Adsorbent material for adsorbing VOCs and preparation method thereof

An adsorption material and adsorbent technology, which is applied in the field of adsorption material for adsorbing VOCs and its preparation, can solve the problems of easy blocking of molecular sieve adsorption channels, decreased adsorption performance, and easy carbon deposition on the surface of molecular sieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

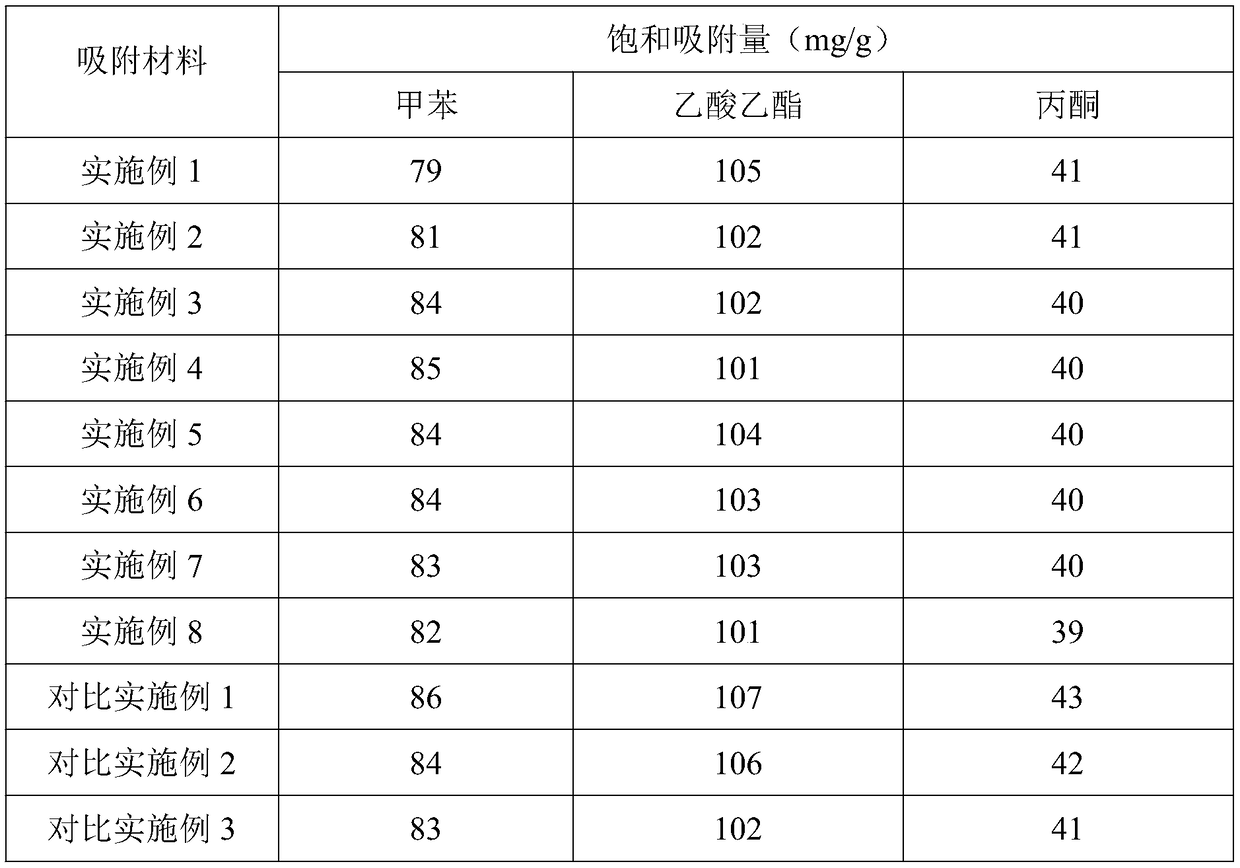

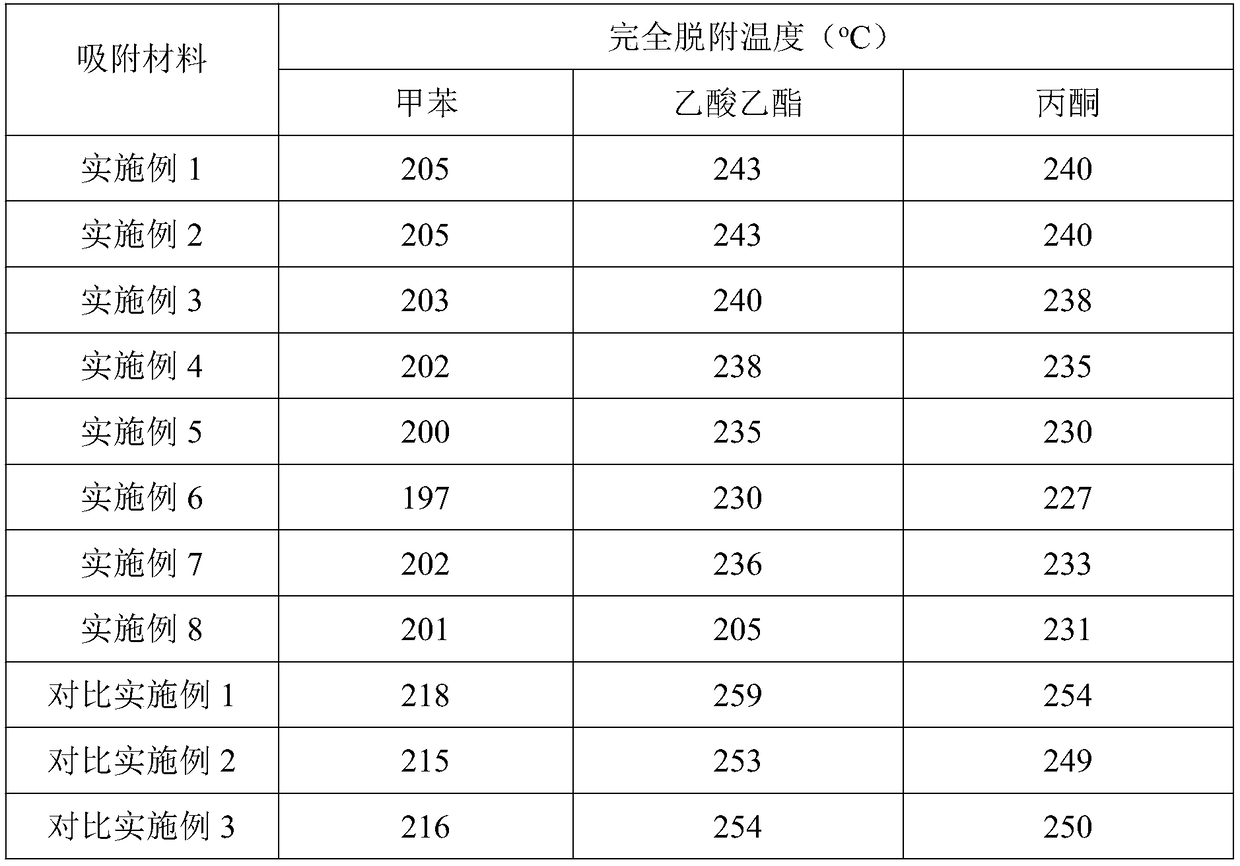

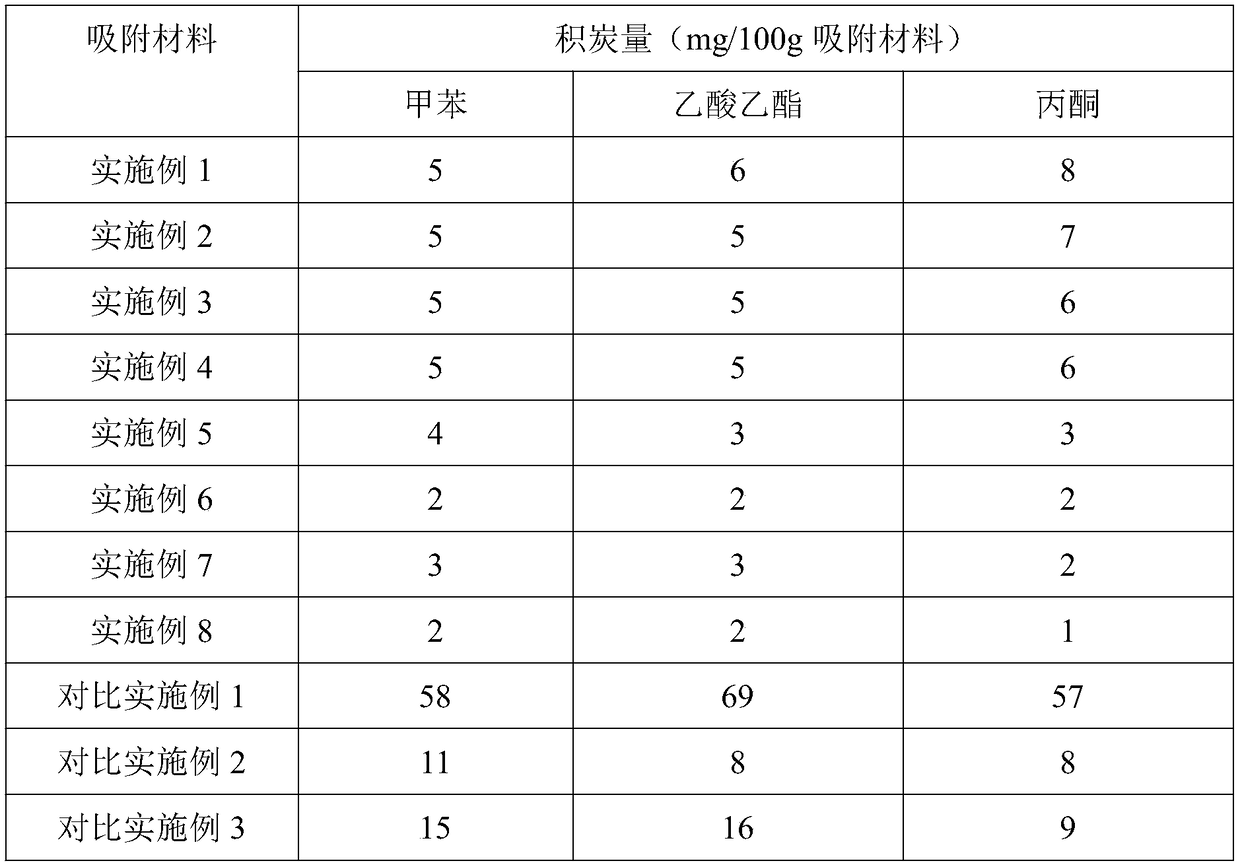

Examples

Embodiment 1

[0020] (1) Pt(NO 3 ) 2 The solution was added to 50g of BN carrier, soaked for 2 hours, then fried in a water bath at 90°C, dried in an oven at 120°C for 8 hours, and finally calcined at 500°C for 4 hours to obtain a Pt / BN catalyst;

[0021] (2) with Ce(NO 3 ) 3 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 The molar ratio of O is 7:3, and 30.39g Ce(NO 3 ) 3 ·6H 2 O and 12.88g Zr(NO 3 ) 4 ·5H 2 O, add 100mL deionized water to dissolve, stir evenly, soak for 2 hours, then fry in a water bath at 90°C, dry in an oven at 120°C for 8 hours, and finally roast at 500°C for 4 hours to obtain CeO 2 -ZrO 2 catalyst;

[0022] (3) Mix molecular sieve, Pt / BN and CeO with ZSM-5 (silicon-aluminum ratio is 300) / USY 2 -ZrO 2 The mass ratio of catalyst is 100:0.5:1, the mass ratio of ZSM-5 (silicon-aluminum ratio is 300) and USY molecular sieve is 1:1, respectively weigh 50g ZSM-5 (silicon-aluminum ratio is 300) molecular sieve, 50g USY Molecular sieves, 0.5g Pt / BN catalyst and 1g CeO 2 -ZrO ...

Embodiment 2

[0025](1) the preparation method of Pt / BN catalyst is identical with embodiment 1;

[0026] (2)CeO 2 -ZrO 2 The preparation method of catalyst is identical with embodiment 1;

[0027] (3) Mix molecular sieve, Pt / BN and CeO with ZSM-5 (silicon-aluminum ratio is 300) / USY 2 -ZrO 2 The mass ratio of the catalyst is 100:0.5:1, and the mass ratio of ZSM-5 (the ratio of silicon to aluminum is 300) to USY molecular sieve is 2:1. Weigh 66.67g of ZSM-5 (the ratio of silicon to aluminum is 300) molecular sieve, 33.33 g USY molecular sieve, 0.5g Pt / BN catalyst and 1g CeO 2 -ZrO 2 For the catalyst, add 100ml of deionized water and stir evenly, then fry it in a water bath at 90°C, dry it in an oven at 120°C for 8 hours, and finally bake it at 500°C for 4 hours to obtain the adsorption material.

[0028] The adsorption performance test of the prepared adsorption material is the same as in Example 1, and its adsorption performance is shown in Table 1.

Embodiment 3

[0030] (1) the preparation method of Pt / BN catalyst is identical with embodiment 1;

[0031] (2)CeO 2 -ZrO 2 The preparation method of catalyst is identical with embodiment 1;

[0032] (3) Mix molecular sieve, Pt / BN and CeO with ZSM-5 (silicon-aluminum ratio is 300) / USY 2 -ZrO 2 The mass ratio of the catalyst is 100:0.5:1, the mass ratio of ZSM-5 (the ratio of silicon to aluminum is 300) to USY molecular sieve is 3:1, and 75g of ZSM-5 (the ratio of silicon to aluminum is 300) and 25g of USY molecular sieve are weighed respectively. Molecular sieves, 0.5g Pt / BN catalyst and 1g CeO 2 -ZrO 2 For the catalyst, add 100ml of deionized water and stir evenly, then fry it in a water bath at 90°C, dry it in an oven at 120°C for 8 hours, and finally bake it at 500°C for 4 hours to obtain the adsorption material.

[0033] The adsorption performance test of the prepared adsorption material is the same as in Example 1, and its adsorption performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com