Corrosion prevention production line for welding epoxy coating in welded steel tube and corrosion prevention process

A technology for welding steel pipes and epoxy coatings, applied in coatings, manufacturing tools, metal processing equipment, etc., can solve the problem of anchor pattern depth, cleanliness level, epoxy coating temperature, solidification slow cooling time cannot be guaranteed, and affect steel pipes Service life and other issues, to solve the effect of incomplete curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

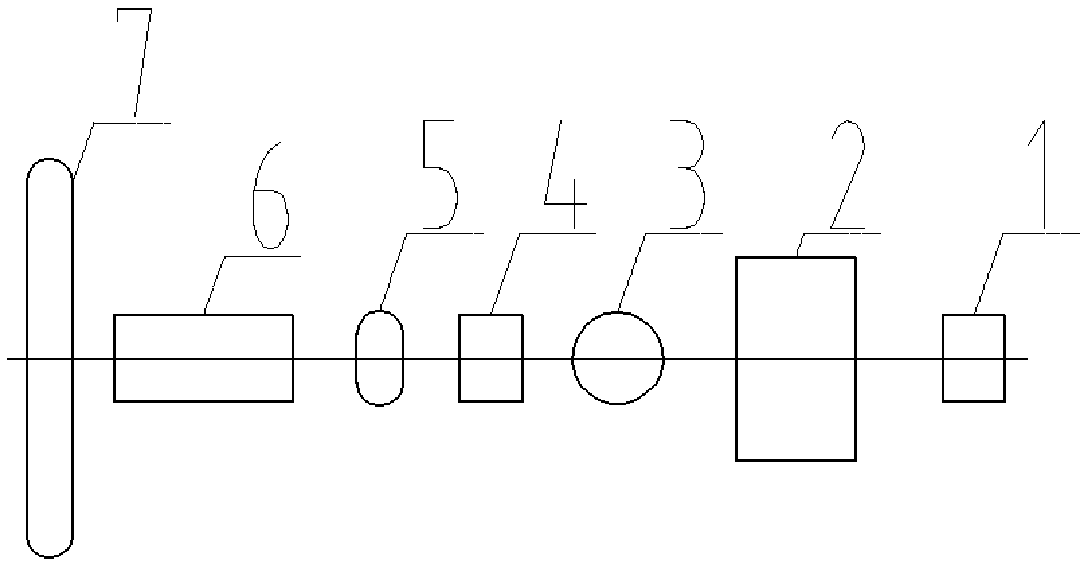

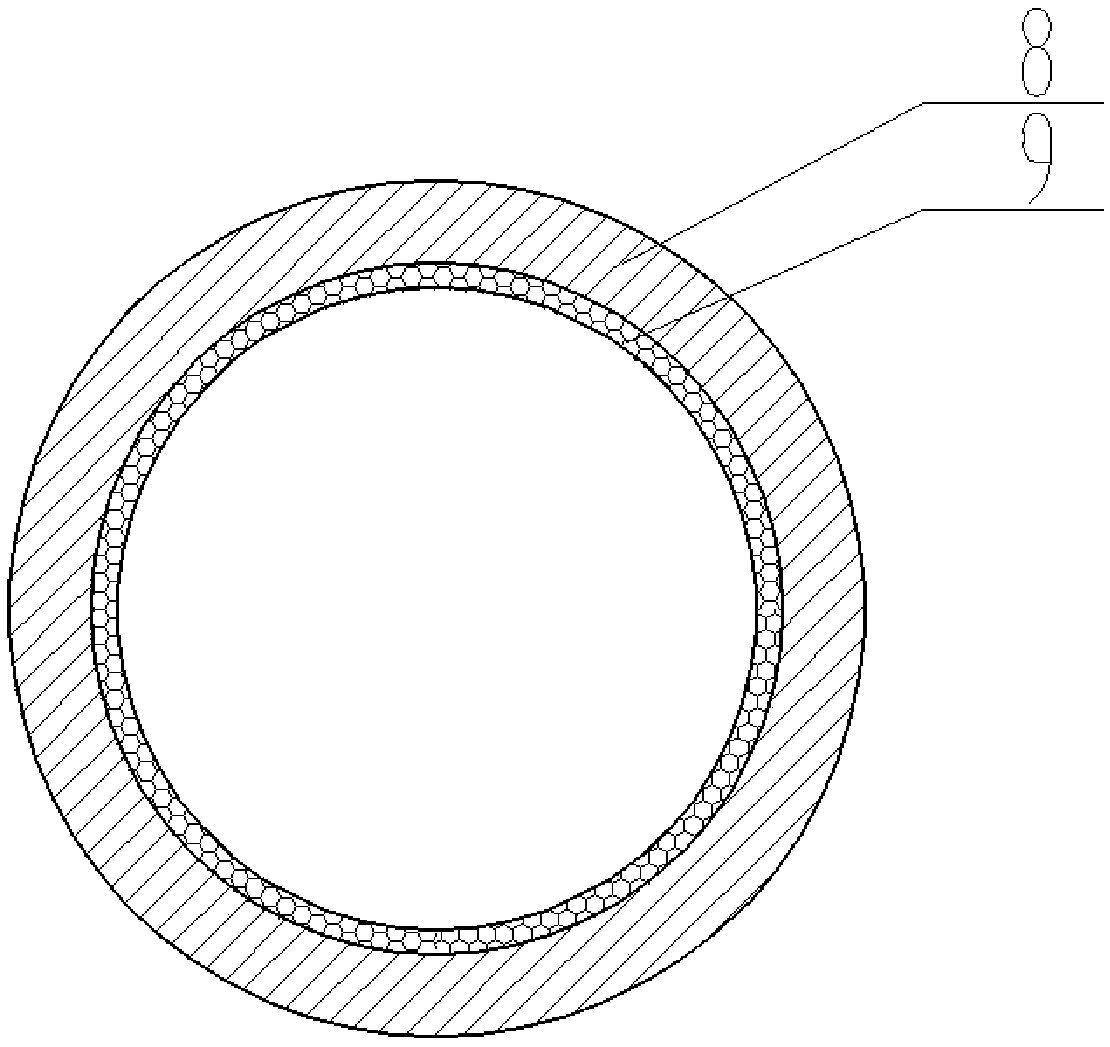

[0021] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0022] An anti-corrosion production line for welding epoxy coating inside welded steel pipes, characterized in that: all production lines are arranged in sequence by a flame preheating furnace 1, an inner wall shot blasting derusting machine 2, an internal purging device 3, an intermediate frequency heating furnace 4, and temperature detection It is composed of an alarm device 5, an epoxy powder coating and dust removal device 6, and a curing slow cooling furnace 7.

[0023] An anti-corrosion process for welding epoxy coatings in welded steel pipes is characterized in that it includes the following process steps:

[0024] (1) Preheating: Preheat the welded steel pipe through the flame preheating furnace Ⅰ1, and burn off the grease on the surface of the steel pipe at the same time;

[0025] (2) Shot blasting: pass the preheated steel pipe through the inner wall shot blasting derusting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com