Device and method for producing zirconium silicate shot through continuous-method ceramic melt atomization

A continuous method, zirconium silicate technology, applied in the direction of ceramic molding machines, abrasives, manufacturing tools, etc., can solve the problems of difficult control of the size range of microbeads, difficult control of melt process parameters, discontinuous production, etc., to achieve easy and precise control , stable melt parameters and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

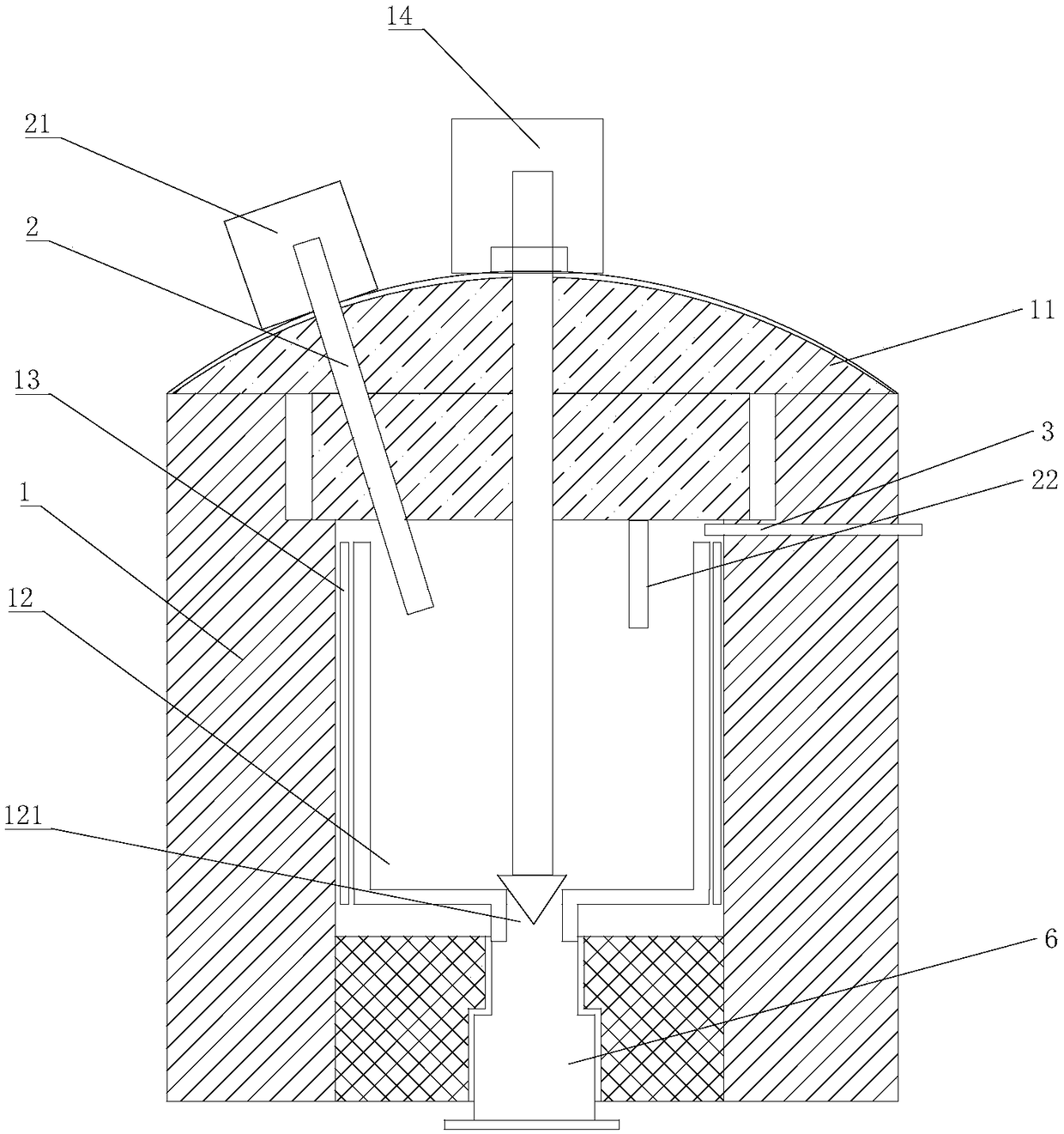

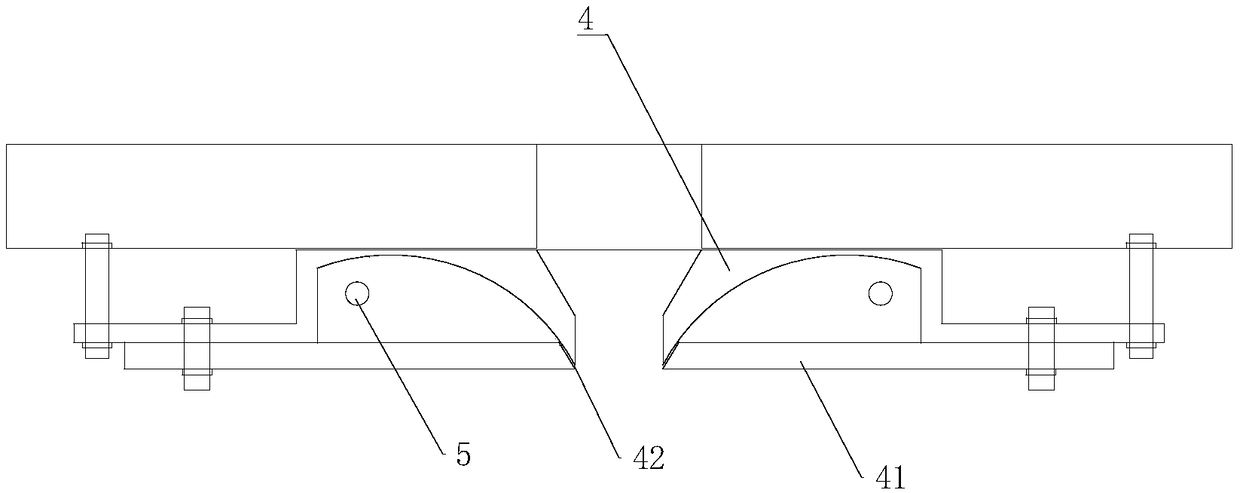

[0028] This embodiment provides a device and method for producing zirconium silicate shot peening by atomizing a continuous method of ceramic melt, the structure is as follows figure 1 and 2 shown.

[0029] A device for continuously producing zirconium silicate shot peening by atomizing ceramic melt, comprising an atmosphere-protected resistance furnace, the atmosphere-protected resistance furnace comprises a furnace body 1 and a furnace cover 11, and the inner cavity of the furnace body 1 is provided with a furnace body for melting ceramic raw materials A tungsten crucible 12 that is a ceramic solution, a leak nozzle 121 is provided at the bottom of the tungsten crucible 12, and a heating element 13 connected to a power supply is arranged on the outside of the tungsten crucible 12. The heating element 13 is a graphite heating element. A tungsten stopper rod 14 that extends into the bottom of the tungsten crucible 12 to control the sealing or opening of the leak nozzle 121 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com