Preparation method of 4-methylimidazole

A technology of methyl imidazole and formaldehyde, applied in the field of preparation of 4-methyl imidazole, can solve problems such as low production efficiency, poor product quality, etc., and achieve the effects of improved production efficiency and product quality, reliable product performance, and small and medium-sized effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

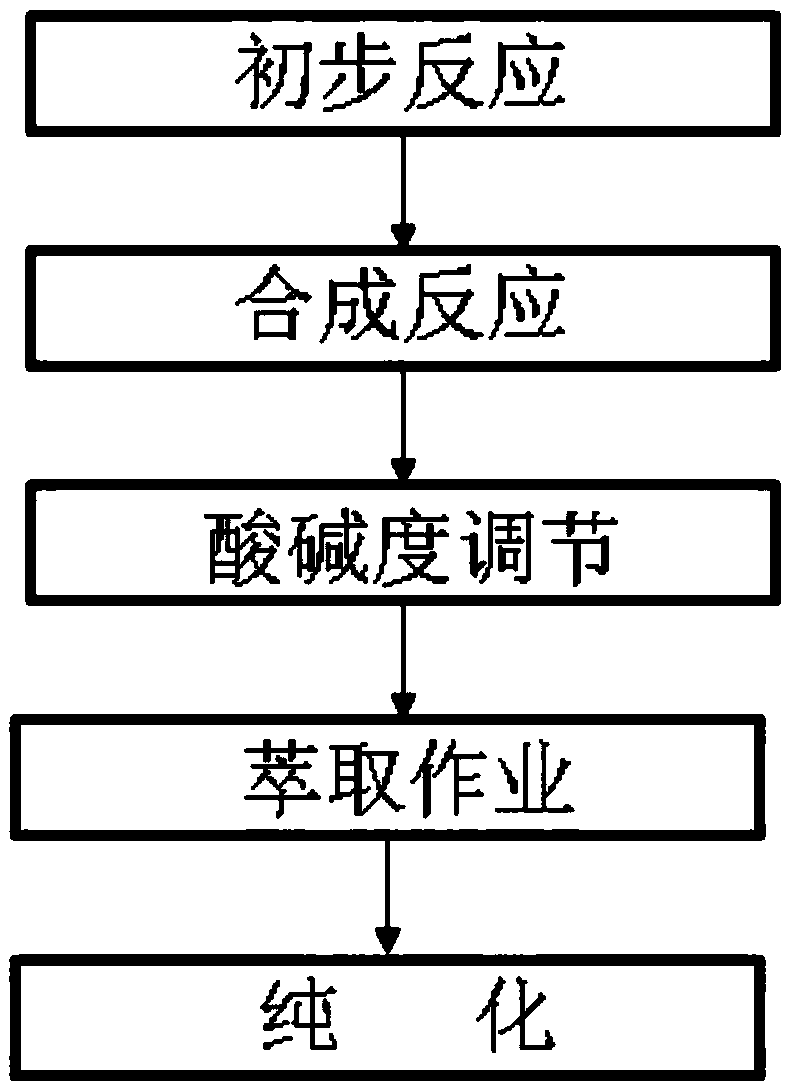

[0022] Such as figure 1 Shown a kind of preparation method of 4-methylimidazole, comprises the steps:

[0023] (1) Preliminary reaction: Add ammonium oxalate, formaldehyde, and methylglyoxal at a uniform speed within 3 minutes to the reaction kettle equipped with a stirring device and a temperature adjustment device, and during the addition process, the materials in the reaction kettle are uniformly separated by the stirring device. For the stirring operation, after completing the addition of materials and continuing to stir for 3 minutes to obtain the mixture, under the condition of keeping the stirring state unchanged, within 10 minutes, the temperature in the reactor was raised to 40°C at a uniform speed, and the mixture was obtained after continuous stirring and heat preservation for 3 hours. Reactants, keep warm and keep the stirring state of the material unchanged for later use;

[0024] (2) Synthesis reaction: Pass ammonia gas into the synthesis reactant prepared in st...

Embodiment 2

[0034] Such as figure 1 Shown a kind of preparation method of 4-methylimidazole, comprises the steps:

[0035] (1) Preliminary reaction: Add ammonium oxalate, formaldehyde, and methylglyoxal at a uniform speed within 10 minutes at the same time to the reaction kettle equipped with a stirring device and a temperature regulating device, and during the addition process, the materials in the reaction kettle are uniformly separated by the stirring device. For the stirring operation, after completing the addition of materials and continuing to stir for 5 minutes to obtain the mixture, under the condition of keeping the stirring state unchanged, within 30 minutes, the temperature in the reactor was raised to 95°C at a uniform speed, and the synthesis was obtained after continuous stirring and heat preservation for 5 hours. Reactants, keep warm and keep the stirring state of the material unchanged for later use;

[0036] (2) Synthesis reaction: Pass ammonia gas into the synthesis rea...

Embodiment 3

[0046] A preparation method for 4-methylimidazole, comprising the steps of:

[0047] (1) Preliminary reaction: Add ammonium oxalate, formaldehyde, and methylglyoxal at a uniform speed within 7 minutes to the reaction kettle equipped with a stirring device and a temperature regulating device, and during the addition process, the materials in the reaction kettle are uniformly separated by the stirring device. For the stirring operation, after completing the addition of materials and continuing to stir for 6 minutes to obtain the mixture, under the condition of keeping the stirring state unchanged, within 20 minutes, the temperature in the reactor was raised to 80°C at a uniform speed, and the synthesis was obtained after continuous stirring and heat preservation for 4 hours. Reactants, keep warm and keep the stirring state of the material unchanged for later use;

[0048] (2) Synthesis reaction: Pass ammonia gas into the synthesis reactant prepared in step (1) at a uniform speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com