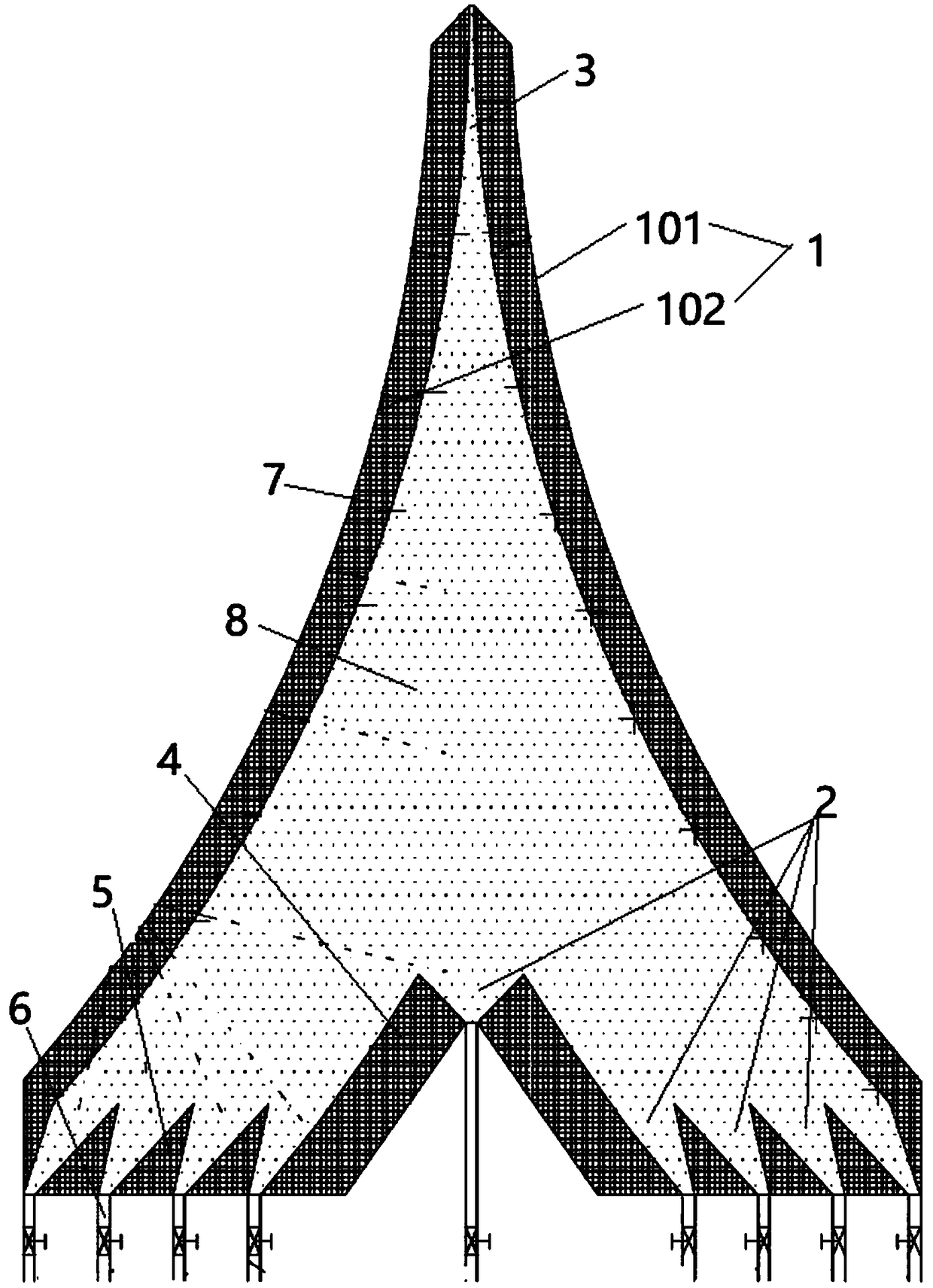

Protein electrophoretic separation and purification method and protein electrophoretic separation and purification device

An electrophoretic separation and purification device technology, which is applied in the field of protein separation, can solve problems such as the inability to separate protein mixtures in batches, and achieve the effects of facilitating batch production, improving separation purity, and concentrating the output liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

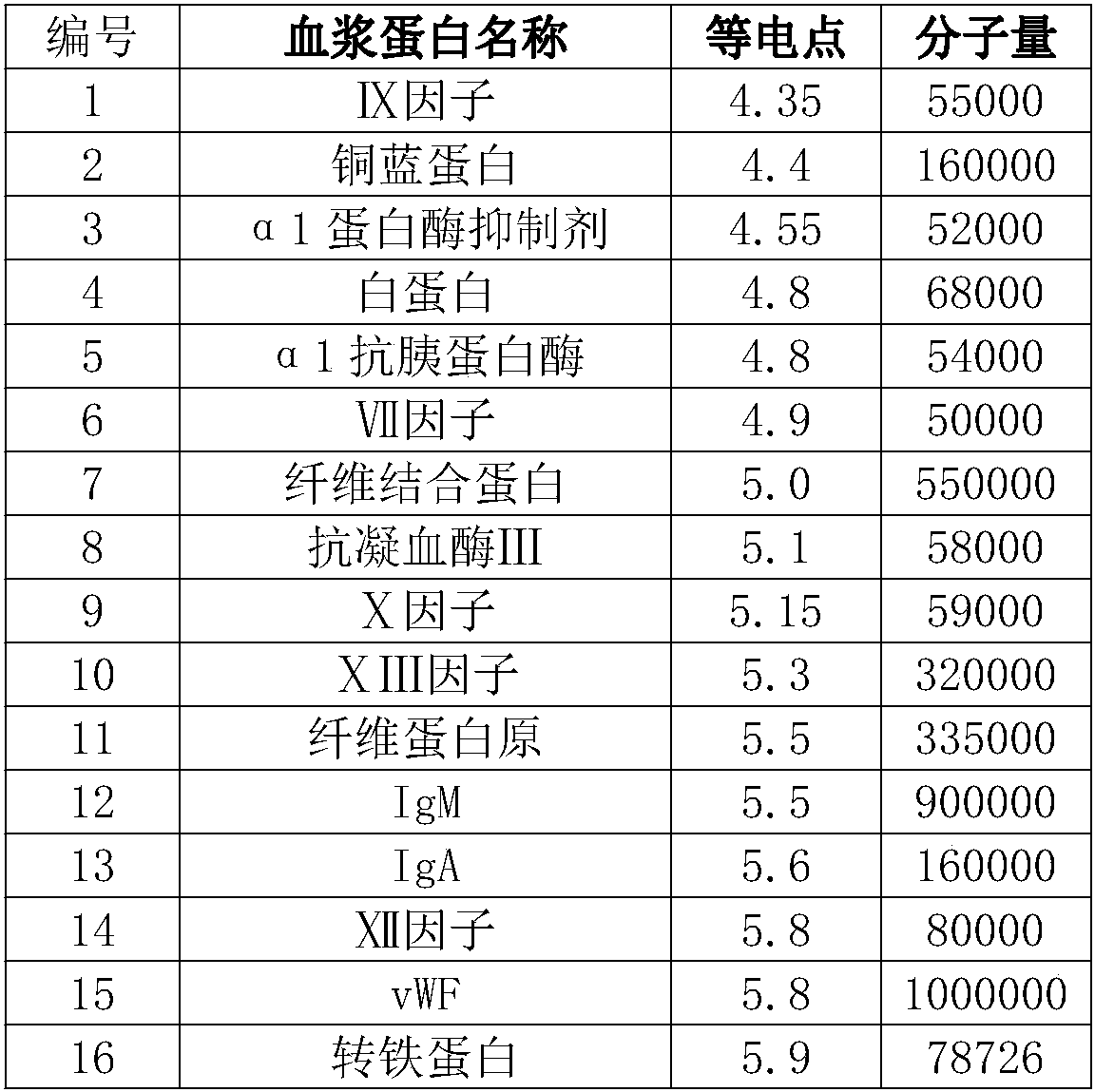

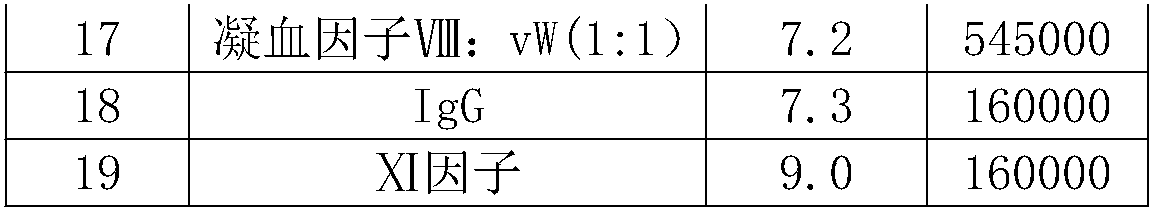

[0025] The components to be separated are: IgG

[0026] A protein electrophoresis separation and purification method, using an electrophoresis separation and purification device to separate the liquid to be separated according to the following steps:

[0027] (1) Adjust the pH of the fused plasma to 7.3, the ionic strength to 0.05-0.10, and control the temperature at 0-6°C;

[0028] (2) Control the electrophoresis power supply voltage in the electrophoresis separation and purification device between 50-300v, and the current is 25-30mA, and the linear flow velocity of the liquid to be separated into the sample feeding slit of the electrophoresis separation and purification device is 0.7-1cm / min;

[0029] (3) Due to the different charges on the surface of different proteins and the different resistance of the molecular size, different proteins will be separated in different bands during the downward movement of the feed liquid, and the IgG will flow out in a straight line in a...

Embodiment 2

[0032] The components to be separated are: IX factor

[0033] A protein electrophoresis separation and purification method, using an electrophoresis separation and purification device to separate the liquid to be separated according to the following steps:

[0034] (1) Adjust the pH of the fused plasma to 4.35, the ionic strength to 0.05-0.10, and control the temperature at 0-6°C;

[0035] (2) Control the electrophoresis power supply voltage in the electrophoresis separation and purification device between 50-300V, and the current is 25-30mA, and the linear flow velocity of the liquid to be separated into the sample feeding slit of the electrophoresis separation and purification device is 0.7-1cm / min;

[0036] (3) In an uncharged state, factor IX is separated at the fastest speed in a straight line in the electrophoretic separation and purification device, while other positively / negatively charged components are separated on both sides of the electrophoretic separation and p...

Embodiment 3

[0039] The components to be separated are: coagulation factor VIII

[0040] A protein electrophoresis separation and purification method, using an electrophoresis separation and purification device to separate the liquid to be separated according to the following steps:

[0041] (1) Adjust the pH of the fused plasma to 7.2, the ionic strength to 0.05-0.10, and control the temperature at 0-6°C;

[0042] (2) Control the electrophoresis power supply voltage in the electrophoresis separation and purification device between 50-300V, and the current is 25-30mA, and the linear flow velocity of the liquid to be separated into the sample feeding slit of the electrophoresis separation and purification device is 0.7-1cm / min;

[0043] (3) Blood coagulation factor VIII is separated at the fastest speed with a straight line trajectory in the electrophoretic separation and purification device in an uncharged state, while other positively / negatively charged components are separated on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com