Plastic-wood material for moisture-proof door board

A technology of plastic wood material and anti-aging agent, which is applied in the field of plastic wood material for moisture-proof door panels, which can solve the problems of shortened service life of plastic wood door panels and easy condensation of water vapor, and achieve the effect of shortening the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

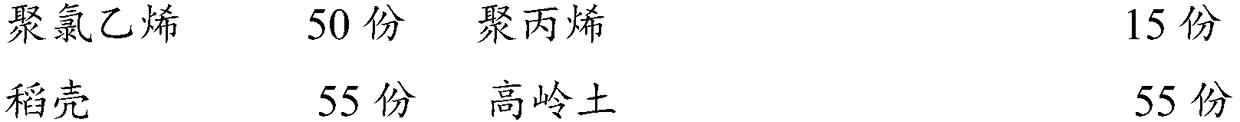

[0020] Plastic wood materials for moisture-proof door panels, according to quality components include:

[0021]

[0022]

[0023] The preparation method is:

[0024] Weigh the components of polyvinyl chloride, polypropylene, rice husk, kaolin, ABS-g-MAH, silicone oil, silane coupling agent, 2,2,4-trimethyl1,2-dihydroquine and stearic acid calcium;

[0025] Put polyvinyl chloride, polypropylene, rice husk and kaolin in a dryer, control the temperature at 60°C, and dry for 50 minutes;

[0026] Add the dried rice husk to a pulverizer and pulverize to 20 mesh to obtain rice husk powder;

[0027] Add rice husk powder, polyvinyl chloride, polypropylene, kaolin, ABS-g-MAH, silicone oil, silane coupling agent, 2,2,4-trimethyl1,2-dihydroquine, calcium stearate to high In the mixer, the mixing speed is 600r / min, the mixing time is 8min, and the mixture is obtained;

[0028] Add the mixture to the twin-screw extruder, control the temperature in the extruder to 185°C, and perform the mixing and gr...

Embodiment 2

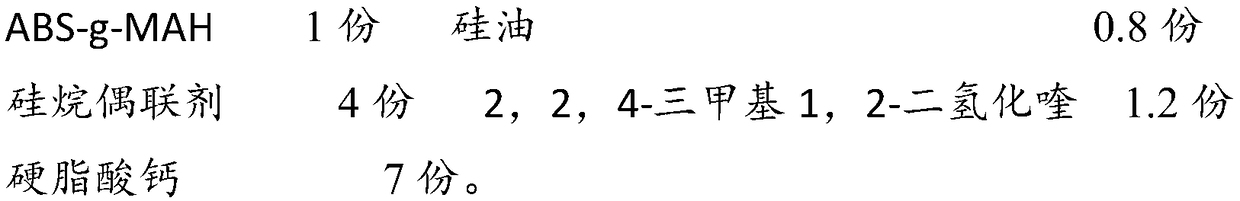

[0031] Plastic wood materials for moisture-proof door panels, according to quality components include:

[0032]

[0033] The preparation method is:

[0034] Weigh the components of polyvinyl chloride, polypropylene, rice husk, diatomaceous earth, PE-g-MAH, silicate, titanate coupling agent, N-phenyl-α-aniline and zinc stearate;

[0035] Put polyvinyl chloride, polypropylene, rice husk and diatomaceous earth in a dryer, control the temperature to 71℃, and dry for 46 minutes;

[0036] Add the dried rice husk to a pulverizer and pulverize to 8 mesh to obtain rice husk powder;

[0037] Add rice husk powder, polyvinyl chloride, polypropylene, diatomaceous earth, PE-g-MAH, silicate, titanate coupling agent, N-phenyl-α-aniline, and zinc stearate to the high mixer In, the mixing speed is 780r / min and the mixing time is 10min to obtain the mixture;

[0038] Add the mixture to the twin-screw extruder, control the temperature in the extruder to 205°C, and perform the mixing and granulation;

[0039...

Embodiment 3

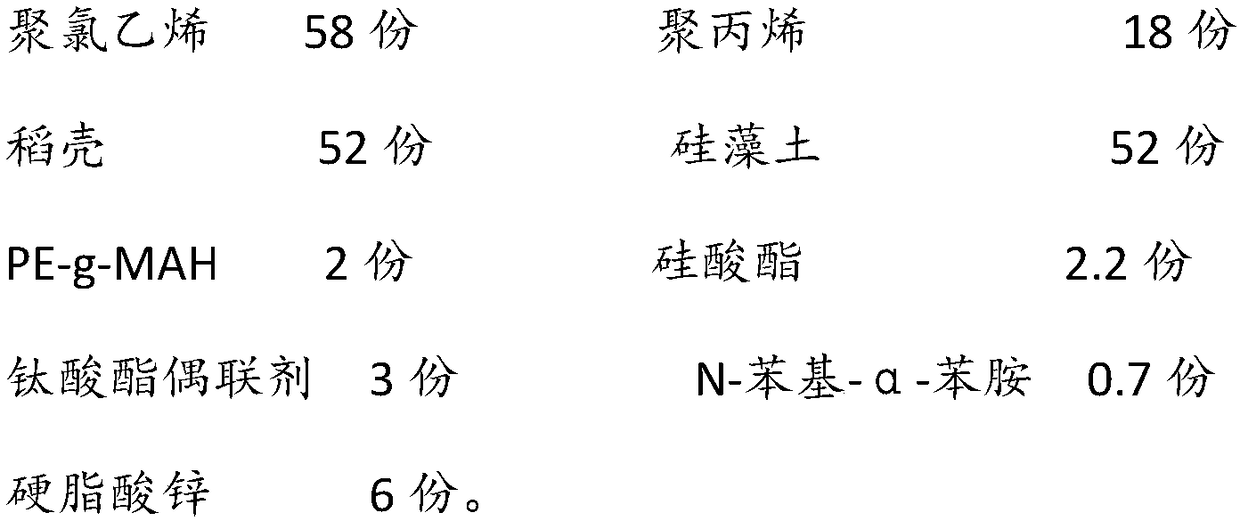

[0041] Plastic wood materials for moisture-proof door panels, according to quality components include:

[0042]

[0043] The preparation method is:

[0044] Weigh the components of polyvinyl chloride, polypropylene, rice husk, talc, PE-g-MAH, phosphate ester, titanate coupling agent, N-phenyl-β-naphthylamine and magnesium stearate;

[0045] Put polyvinyl chloride, polypropylene, rice husk and talcum powder in a dryer, control the temperature at 75℃, and dry for 30 minutes;

[0046] The dried rice husk is added to the pulverizer and crushed to 5 mesh to obtain rice husk powder;

[0047] Add rice husk powder, polyvinyl chloride, polypropylene, talc, PE-g-MAH, phosphate, titanate coupling agent, N-phenyl-β-naphthylamine, and magnesium stearate to the high-mixer , The mixing speed is 900r / min, the mixing time is 15min, and the mixture is obtained;

[0048] Add the mixture to the twin-screw extruder, control the temperature in the extruder to 185°C, and perform the mixing and granulation;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com