Spinning method for regenerated yarn with optimal fiber component

A technology of fiber groups and fibers, applied in the direction of fiber mixing, fiber treatment, natural fibers, etc., to achieve the effect of improving environmental protection performance and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

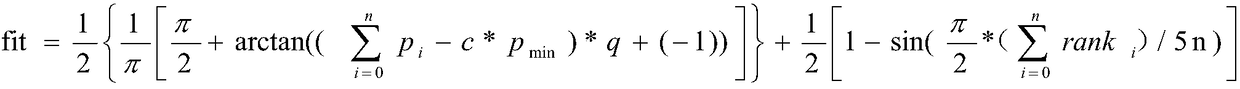

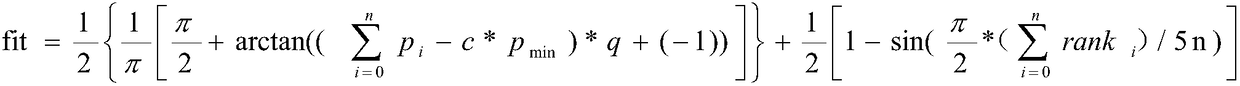

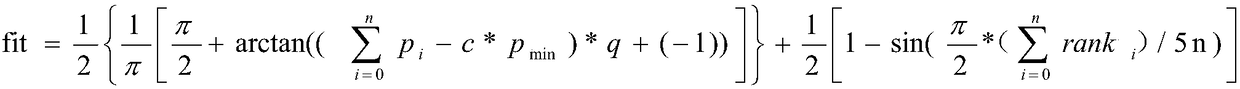

Image

Examples

Embodiment 2

[0049] Step 1: Obtain the filling cotton to be used, crush the filling cotton with a pulverizer to obtain cotton wool for use, and the cotton wool ingredients are: 90 parts of cotton wool, 9 parts of milk protein fiber, 14 parts of chitin fiber, and 8- 10 parts, mixed thoroughly, put in and soaked in a collagen solution with a mass volume ratio of 1.5%, slowly heated up to 52°C, kept warm for 1.5H, then taken out, and dried evenly with hot air below 40°C, the drying time is 2.5H, obtain the first mixture after drying;

[0050] Step 2: Put the dried first mixture obtained in step 1 into the pre-prepared solution for soaking, the soaking time is 3H, and the hot air below 40°C is used for uniform drying, and the drying time is 2.5H, and the dried The second mixture after drying; wherein, the composition of the solution is: a mixed solution of 2-10 parts of polyacrylic acid, 6 parts of vinyl acetate, 7.5 parts of sorbic acid, 25 parts of sodium chloride, and 80 parts of distilled ...

Embodiment 3

[0054] Step 1: Obtain the filling cotton to be used, crush the filling cotton with a pulverizer to obtain cotton wool for use, and the ingredients of cotton wool are: 100 parts of cotton wool, 10 parts of milk protein fiber, 15 parts of chitin fiber, and 10 parts of bamboo pulp fiber , put it in after mixing thoroughly, soak it in the collagen solution with a mass volume ratio of 1.5%, slowly raise the temperature to 55°C, keep it warm for 1.5H, take it out, and use hot air below 40°C to dry it evenly, and the drying time is 3H. obtaining the first mixture after drying;

[0055] Step 2: Put the dried first mixture obtained in step 1 into the pre-prepared solution for soaking for 2-4 hours, and use hot air below 40°C for uniform drying for 3 hours to obtain The second mixture after drying; wherein, the composition of the solution is: a mixed solution of 2-10 parts of polyacrylic acid, 7 parts of vinyl acetate, 8 parts of sorbic acid, 30 parts of sodium chloride, and 85 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com