Piled anchor and liquid nitrogen frozen soil wall combined support implementation method and supporting structure manufactured through method

An implementation method and composite support technology are applied in sheet pile wall, foundation structure engineering, excavation and other directions, which can solve the problems of long formation time of frozen soil wall, low construction efficiency of support structure, complicated construction, etc., and achieve convenient and fast construction. , Small footprint, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

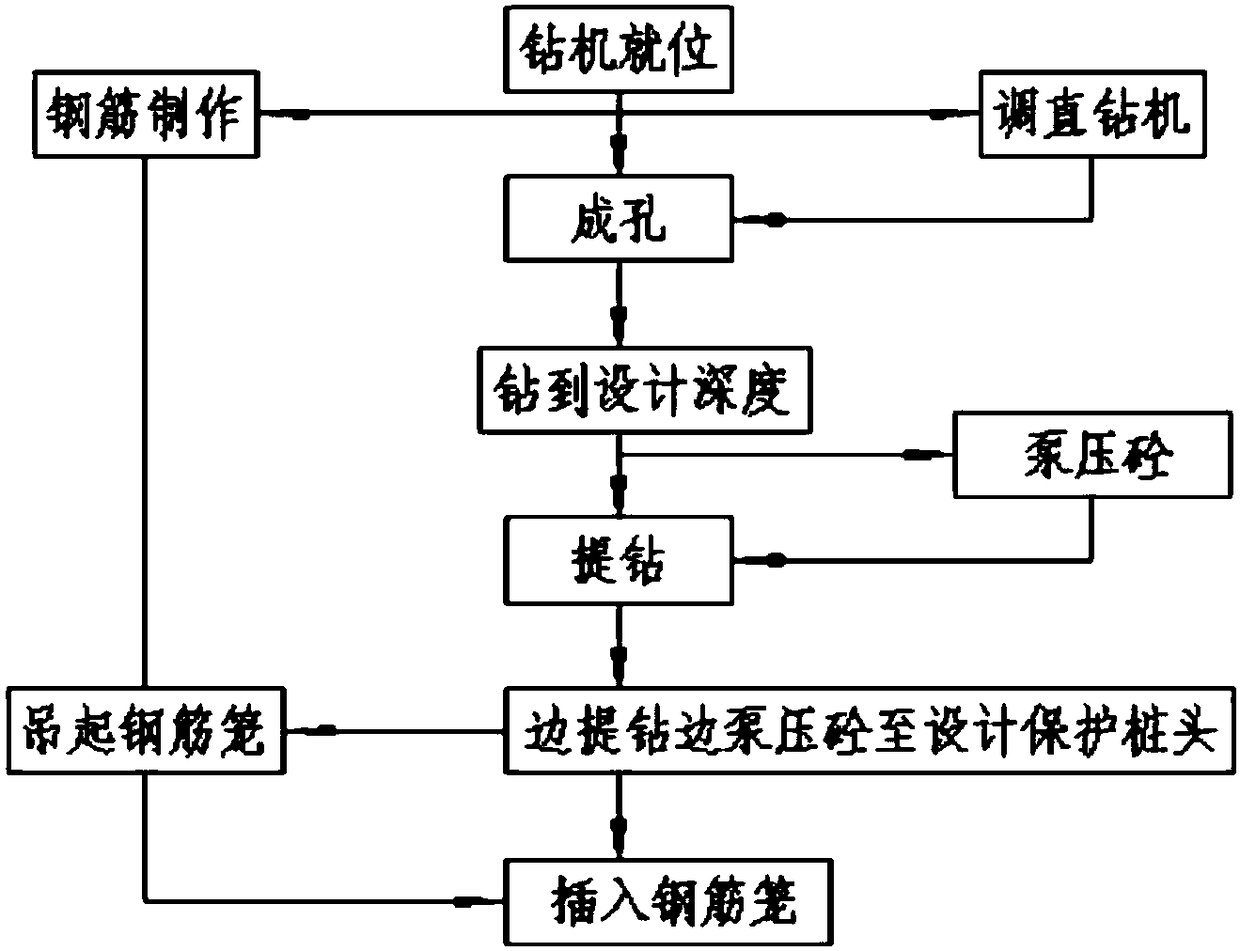

[0045] The specific implementation method is as follows:

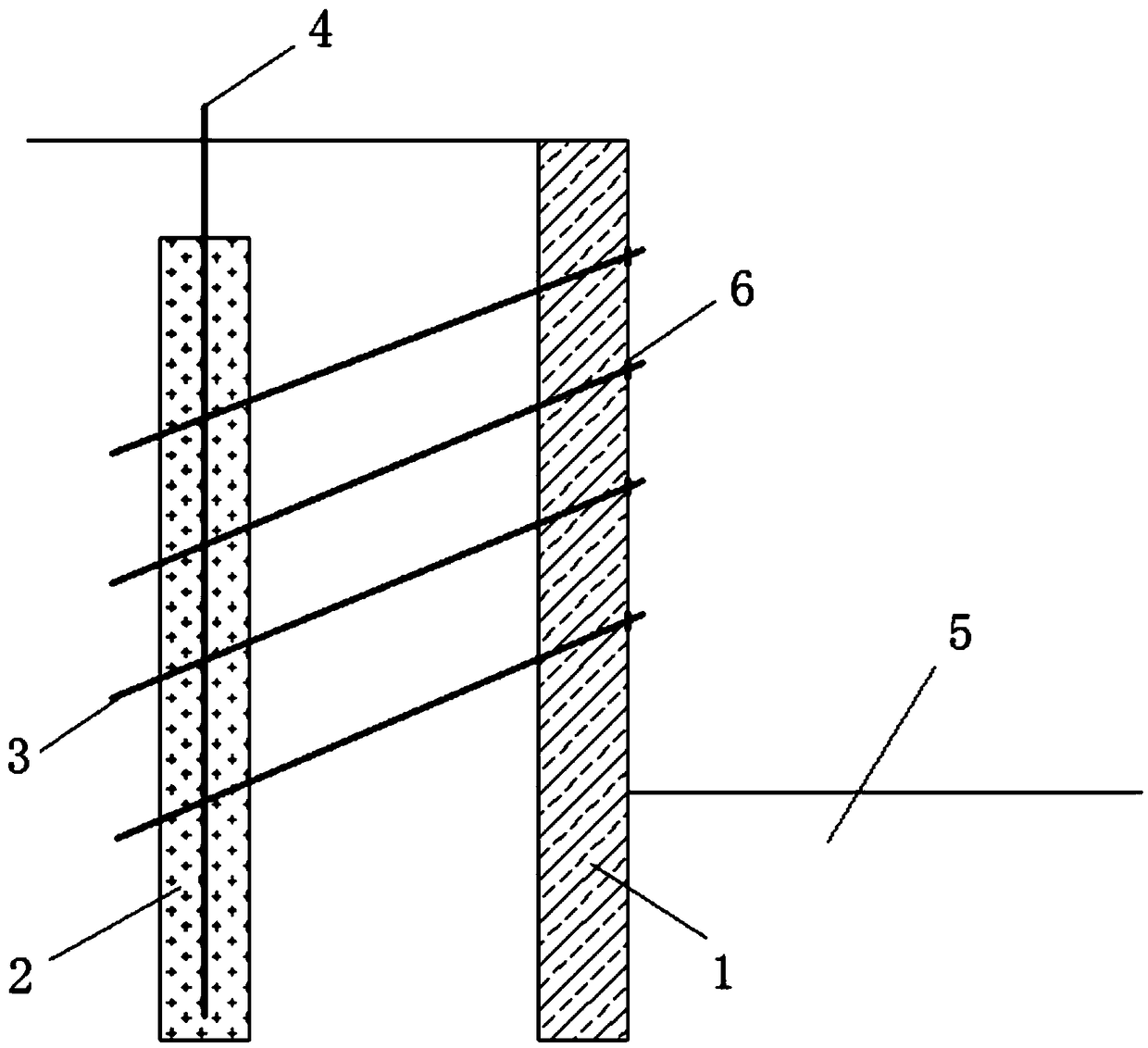

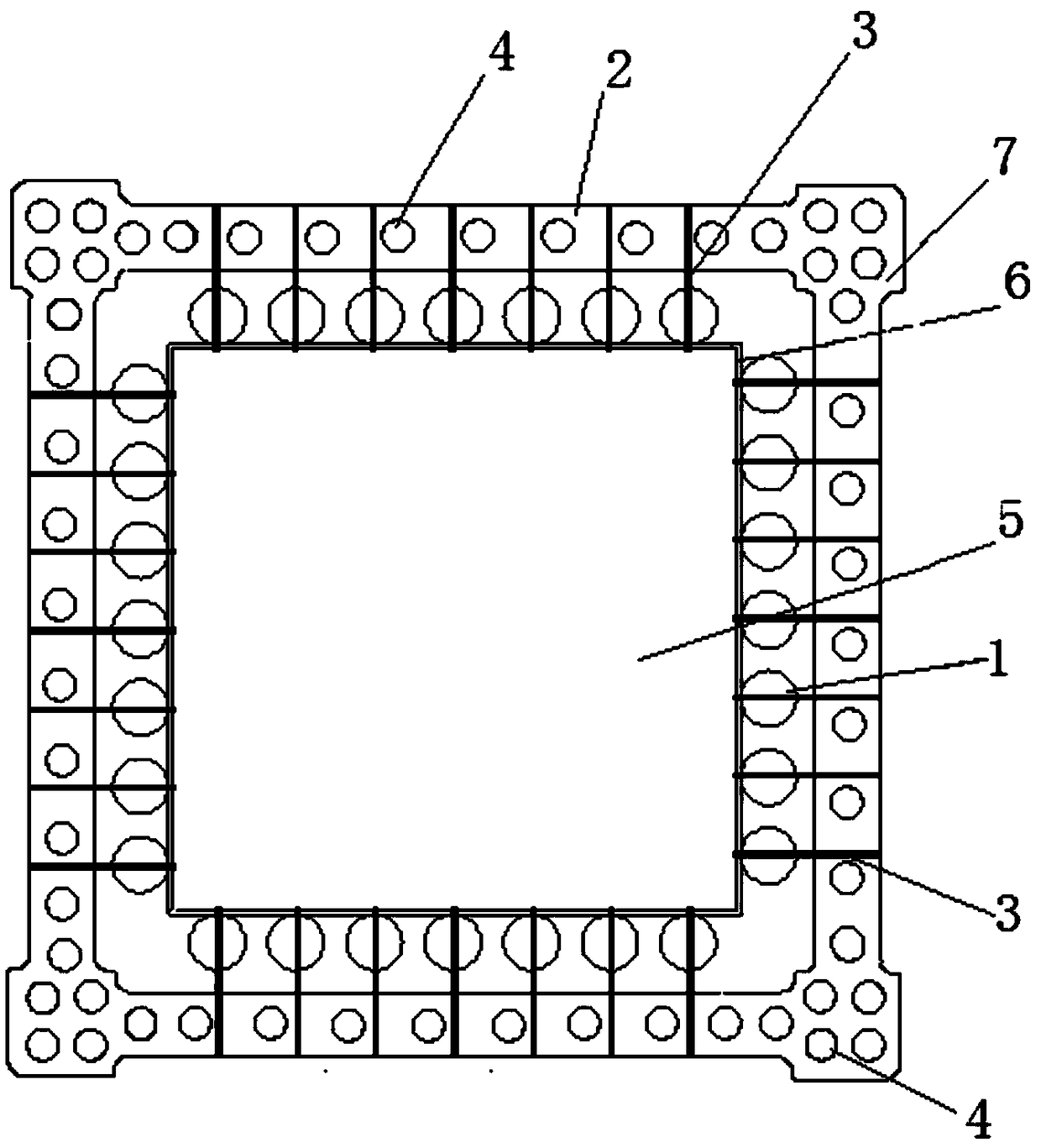

[0046] Step 1. First, set up a drainage system to prevent groundwater from affecting the construction of the supporting structure. Set up surface drainage, internal drainage of the support, and drainage of the foundation pit 5 to prevent the soil from being saturated and reduce the effect on the slope protection pile 1. Hydrostatic pressure on the surface.

[0047] Disperse water and various drainage ditches can be made around the top of the foundation pit 5. Drainage ditches and water collection pits can be set in the foundation pit 5. The distance between the drainage ditches and water collection pits and the side wall is 0.5~1.0m, and the water collection pits are accumulated It should be taken out in time.

[0048] Note: When the water pressure on the side wall of the foundation pit 5 is high, after the step 2 slope protection pile 1 is set, a horizontal water pipe with a length of 400-600mm and a diameter of not less th...

Embodiment 2

[0080] The difference between this embodiment and the first embodiment is that in step (2) of step 4, the liquid nitrogen supply pipeline adopts a pipeline of different materials. Freezing tube 4 uses Ф108×8mm low temperature resistant plastic pipe, temperature measurement tube uses Ф89×5mm low temperature resistant plastic pipe, liquid supply pipe and system connection pipe uses Ф32×3.0mm R304 low temperature resistant plastic pipe, plastic material can be PVC, PPR, ABS , PE and other plastic materials. In this embodiment, there is no need to remove the freezing tube 4 in step (4) of step 3. The steps of removing the freezing pipe 4 are reduced, the construction steps are reduced, and the efficiency is improved.

Embodiment 3

[0082] The difference between this embodiment and Embodiment 1 is that the shape of the liquid nitrogen frozen soil wall 2 does not adopt an upright flat wall but a curved frozen soil wall. In step 1, the freezing pipe 4 is arranged along a curve. The span of the curved frozen soil wall is small, and the rigidity of the end of the liquid nitrogen frozen soil wall 2 and the overall stability of the liquid nitrogen frozen soil wall 2 must be ensured. The frozen column pile 7 needs to bear the thrust transmitted by the curved frozen soil wall and within the range of the pile The pressure of the earth. The tension side of the liquid nitrogen frozen soil wall 2 is also provided with steel bars, glass fiber bars or bamboo bars as tensile materials. This can meet the needs of more shapes of foundation pits 5.

[0083] Attention should be paid to the use of this composite supporting structure during excavation in foundation pit 5:

[0084] (1) In order to ensure that there is absolutely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com