Automatic production line control system and method

A technology for automated production lines and control systems, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as the inability to realize multiple production line control, single production line control, etc., to improve coordination efficiency and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

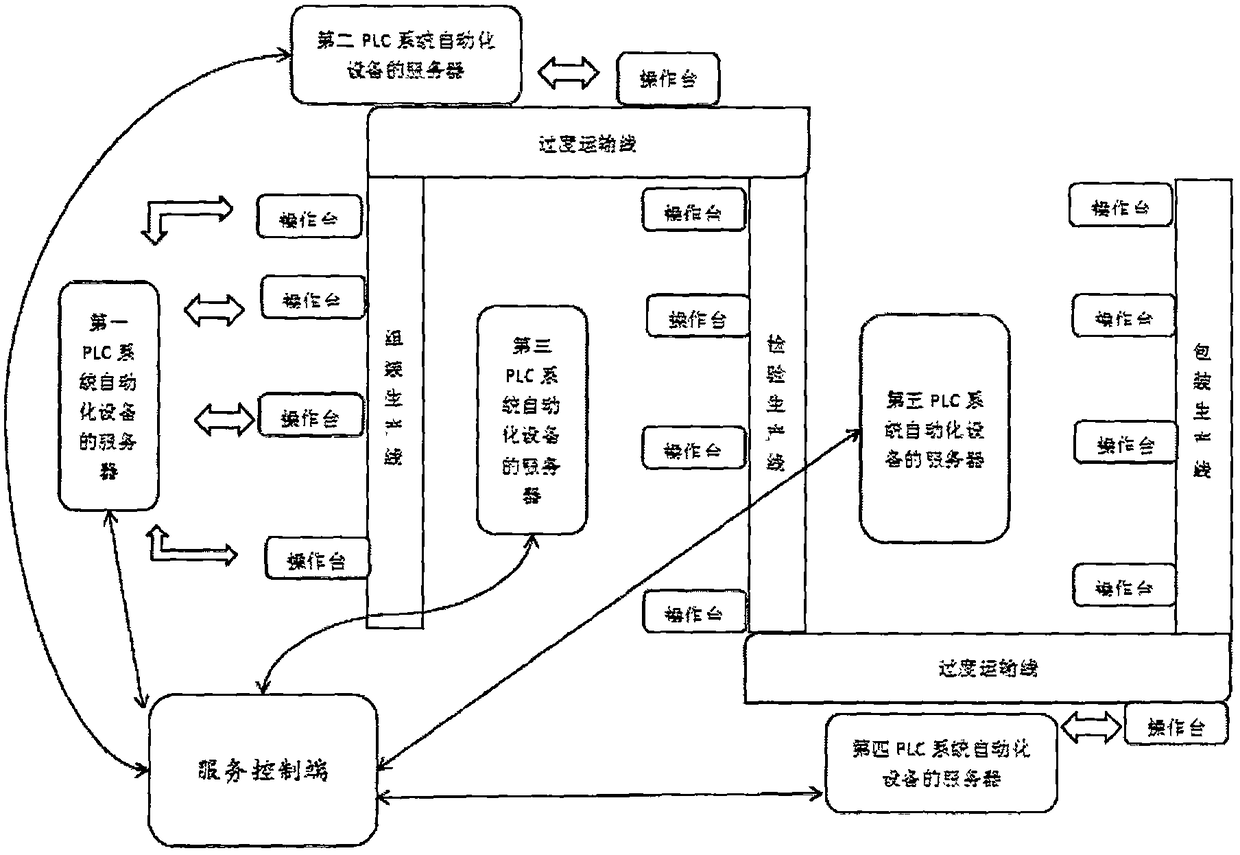

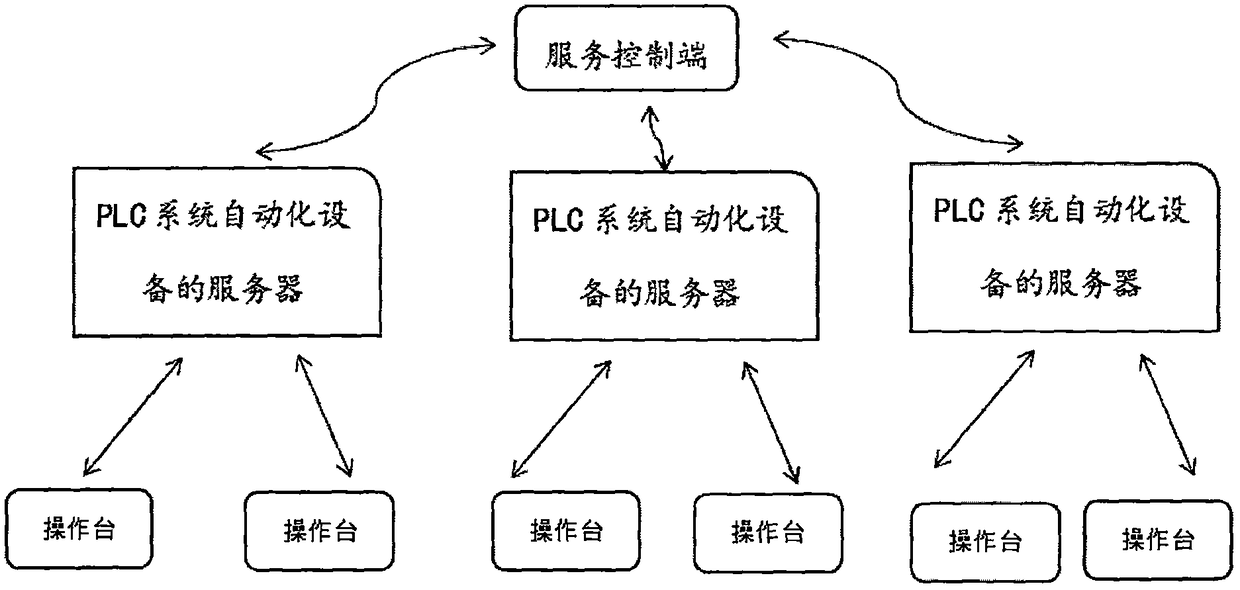

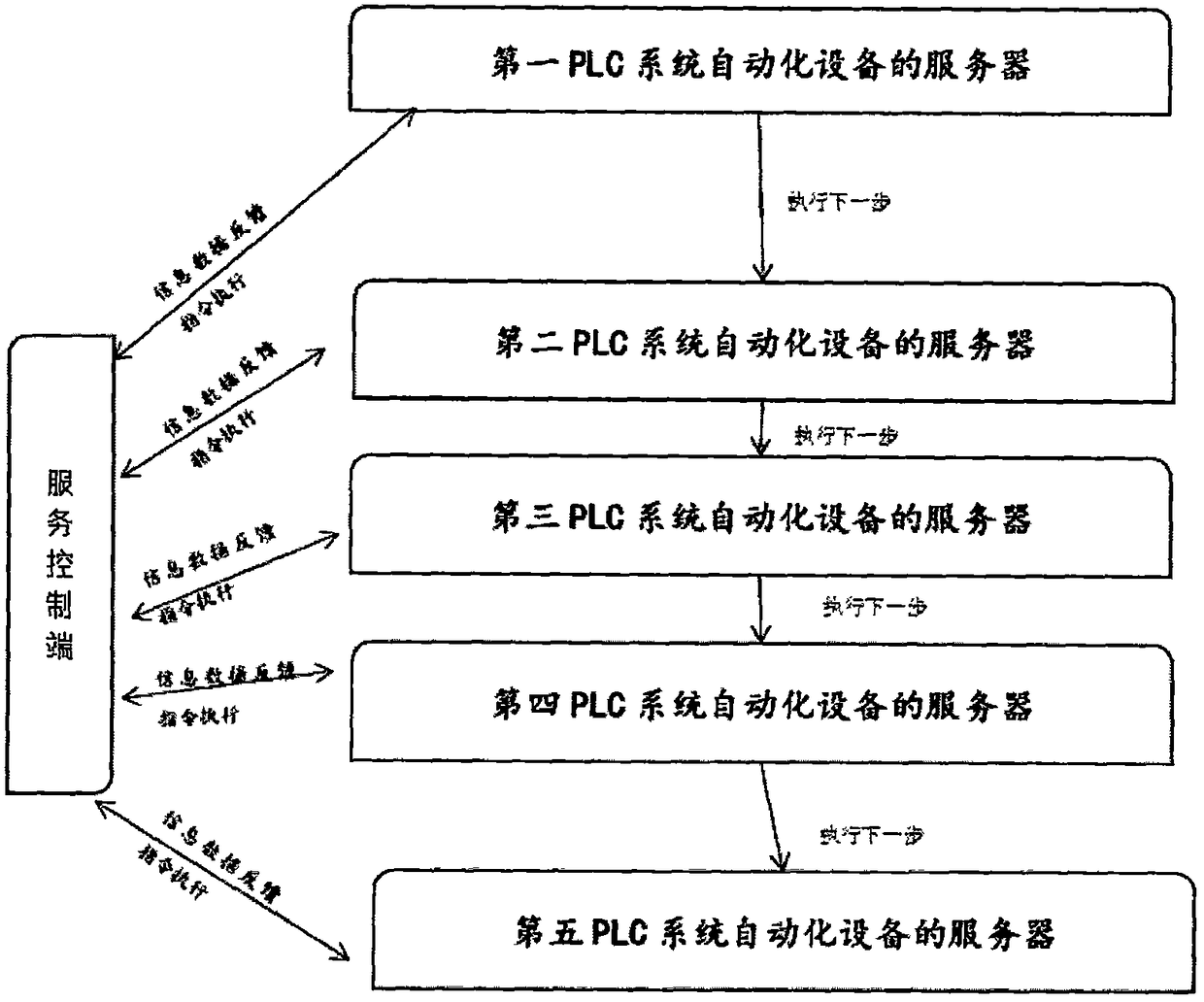

[0030] Such as figure 1 As shown, an automated production line control system includes a service control terminal, a plurality of PLC system automation equipment, the service control terminal and the plurality of PLC system automation equipment communicate through wireless or wired networks respectively, and the PLC system automation equipment includes multiple PLC system automation equipment. An operation desk, and RFID radio frequency reading and writing system, production line, RFID radio frequency reading and writing system includes information reading point and RFID label, and information reading point is arranged on the described production line, and several tooling boards are also placed on the production line, and tooling board An RFID tag is set; the information reading point reads the data information in the RFID tag on the tooling board and transmits the data information to the PLC system automation equipment, and the PLC system automation equipment feeds back the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com