Deodorizing, ventilating and disinfecting method of livestock breeding shed based on adsorption filtration

A technology of adsorption filtration and disinfection method, which is applied in the field of livestock breeding and ventilation, can solve the problems of surrounding air pollution and other problems, and achieve the effects of saving energy, improving air quality, and saving breeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

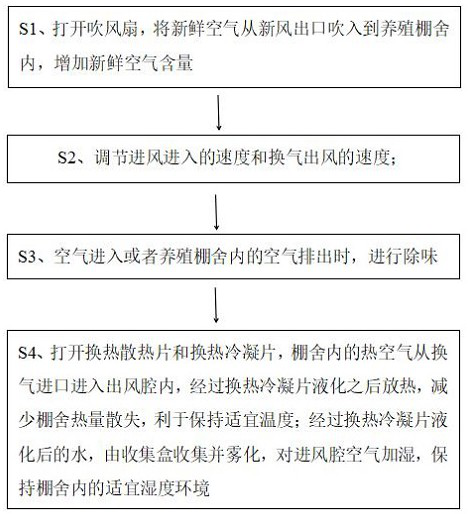

[0050]Such asfigure 1 As shown, a deodorization and ventilation disinfection method for livestock breeding sheds based on adsorption filtration includes the following steps:

[0051]S1. Install the deodorizing, ventilation and disinfection device on the side wall of the breeding shed, turn on the blowing fan 6, and blow fresh air into the breeding shed from the fresh air outlet 9 to increase the fresh air content.

[0052]S2. By controlling the forward rotation or reverse rotation of the first motor 18, the windshield amount of the first baffle 20 and the second baffle 21 is indirectly controlled, and the speed of the inlet wind and the speed of the ventilation outlet are adjusted.

[0053]S3. When air enters or the air in the breeding shed is discharged, the filter screen 26 provided by the blowing fan 6 or the exhaust fan 11 is used to deodorize, and the first filter mechanism 7 separates the second filter mechanism 12 for adsorption, deodorization and deodorization. The ultraviolet lamp 1...

Embodiment 2

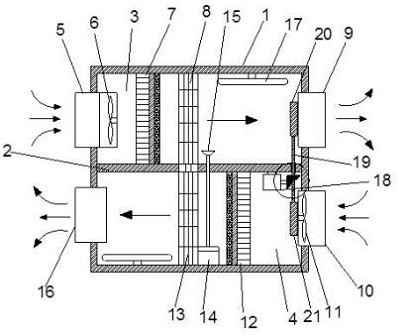

[0059]Such asFigure 2-5As shown, a deodorizing and ventilating disinfection device for livestock breeding sheds based on adsorption and filtration; comprising a housing 1; the housing 1 is provided with a transverse partition 2 inside which connects the housing 1 Divided into two upper and lower cavities, the upper part of the partition 2 is the air inlet chamber 3, and the lower part of the partition 2 is the air outlet chamber 4; one end of the air inlet chamber 3 is provided with a fresh air inlet 5, and the fresh air inlet is provided inside The blowing fan 6 blows fresh air into the air inlet cavity 3; the air outlet side of the blowing fan 6 is provided with a first filter mechanism 7, and the first filter mechanism 7 is provided inside the air inlet cavity 3. The other side of a filter mechanism 7 is provided with a heat exchange fin 8, and the other side of the heat exchange fin 8 is provided with an ultraviolet lamp 17, which is connected to the inner wall of the housing 1;...

Embodiment 3

[0075]On the basis of the second embodiment, when the air volume adjustment mechanism is adjusting, when the air inlet volume needs to be increased, the air volume should be reduced accordingly. The first motor 18 rotates to drive the active bevel gear 22 and The driven auxiliary gear rotates, and the driven bevel gear 23 drives the threaded rod 19 to move toward the ventilation inlet 10 through the internal threaded hole, until the first baffle 20 is completely separated from the fresh air outlet 9, and the second file completely blocks the ventilation inlet 10. Increase the air outlet area of the fresh air outlet 9 and increase the fresh air volume; when ventilation is required, increase the air volume to make the first motor 18 rotate in reverse, and the threaded rod 19 drives the first baffle and the second baffle Moving toward the fresh air outlet 9, the second baffle is completely separated from the ventilation inlet 10, and the first baffle 20 completely shields the fresh a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com