Thermistor Hold Assemblies for High Current Charging Connectors

A technology for charging connectors and thermistors, which is applied to thermistors, thermometers with direct heat-sensitive electric/magnetic elements, parts of connecting devices, etc., can solve the problems of reducing process flexibility and achieve The effect of flexible use and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

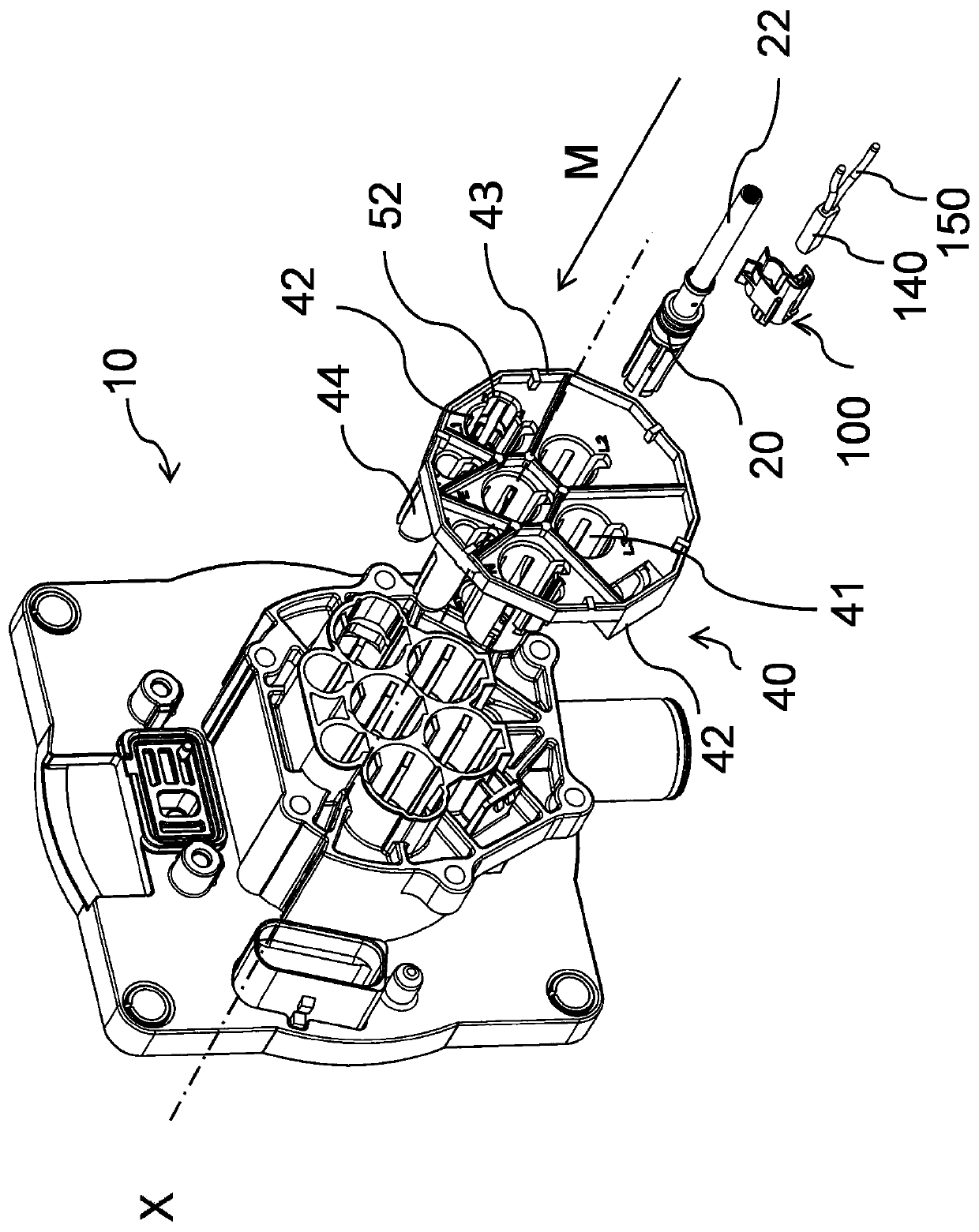

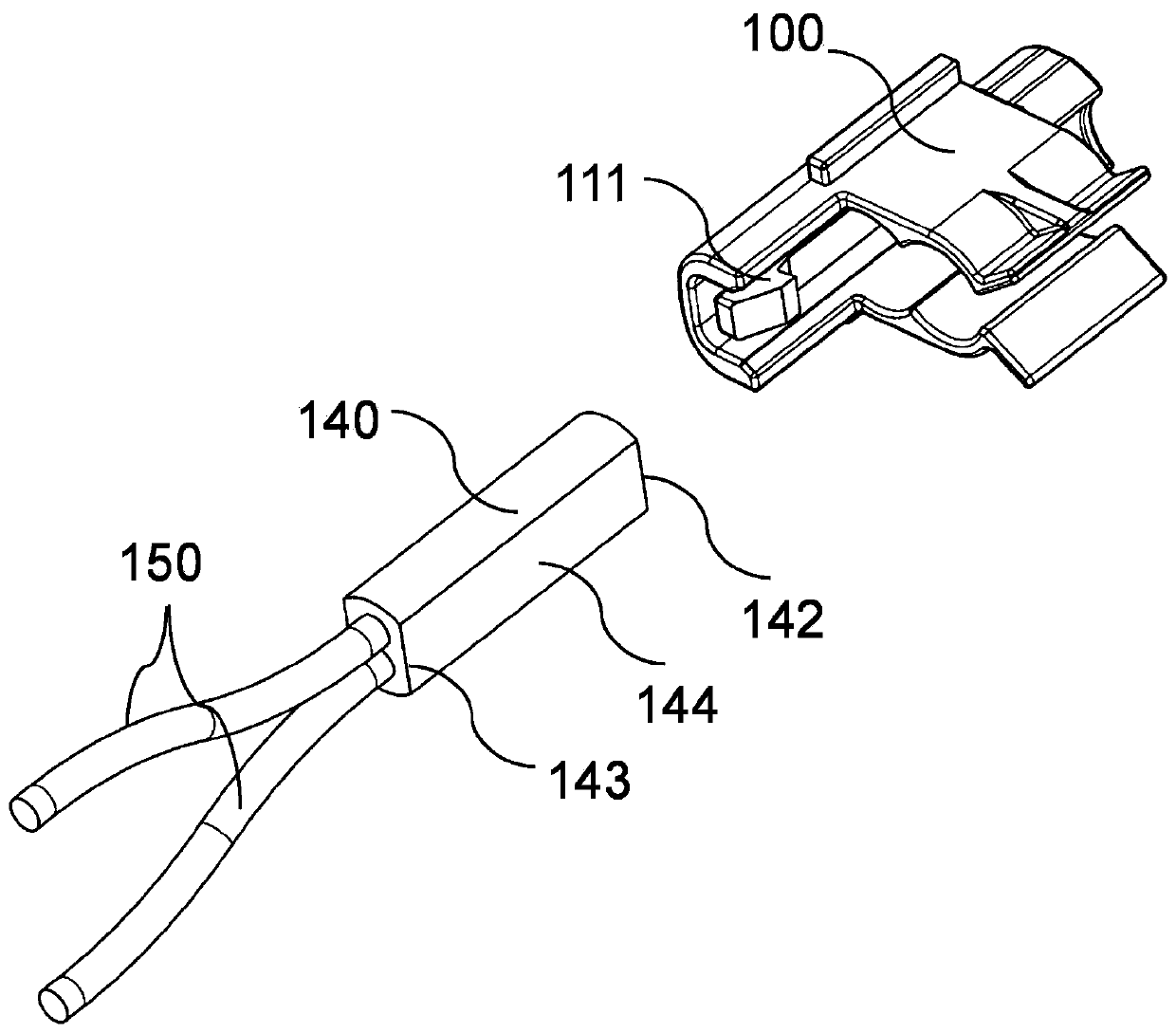

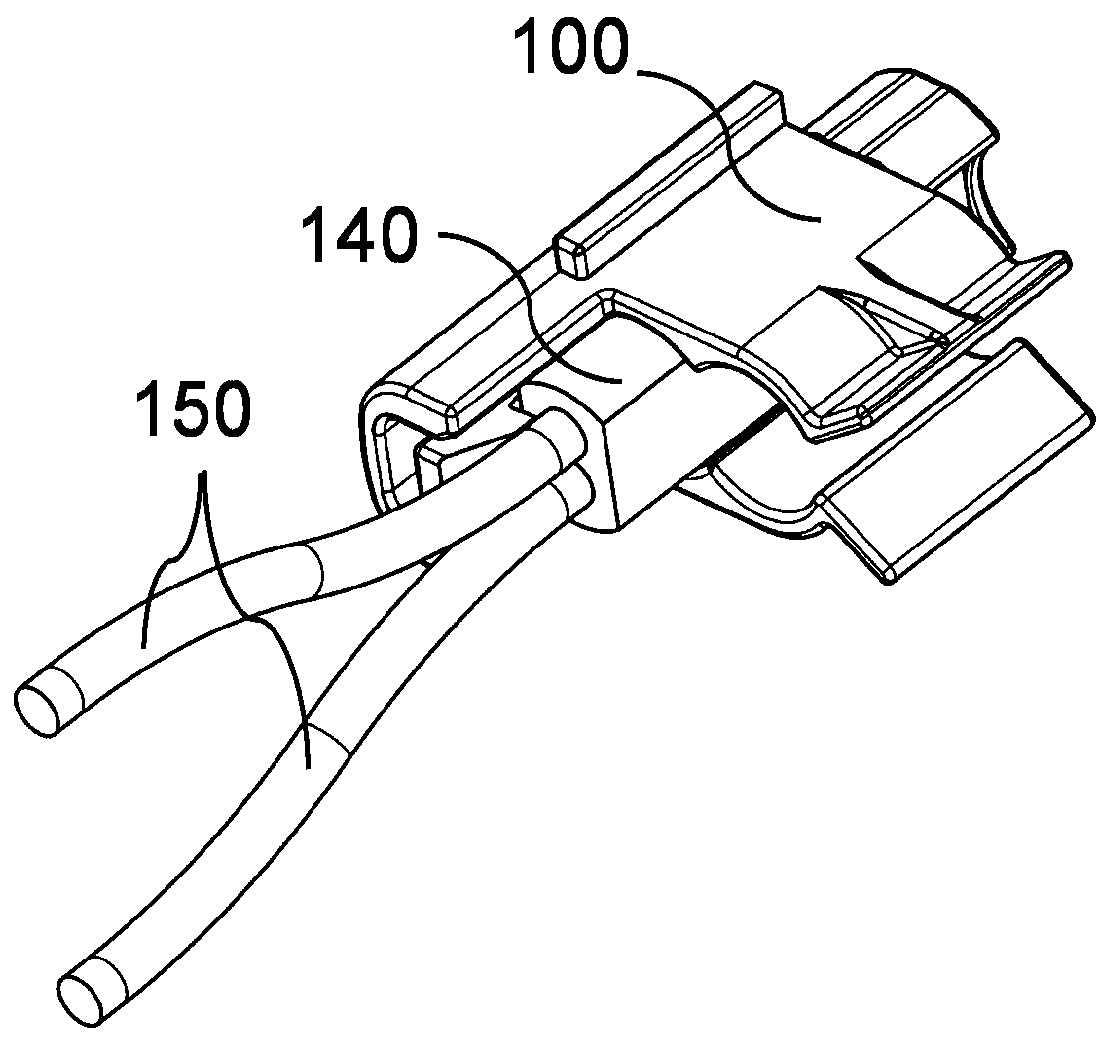

[0028] figure 1 An exploded perspective view of a thermistor retaining assembly for a high current charging connector including a terminal retaining structure 40 is shown. The terminal holding structure 40 is attachable to the high current charging connector housing 10 . The terminal holding structure 40 includes a channel 41 to guide the high current wire 22 through the terminal holding structure 40 . The terminal holding structure 40 includes a clip cavity 52 extending along the mating axis X of the high current charging connector housing 10 , and wherein the clip cavity 52 extends into the channel wall 42 perpendicular to the mating axis. The assembly includes a thermistor holding clip 100 adapted to hold a thermal sensor 140 and configured to clip onto the high current wire 22 . At a stage when the thermistor retention assembly is finally assembled, the thermistor retention clip 100 is at least partially received and retained in the clip cavity 52 . The terminal holding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com