White light series organic electroluminescence device

An electroluminescent device, white light technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve problems such as angle dependence considerations, complex structures, etc., to achieve optimized devices, wide application fields, simplified structures and preparation processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A white light series organic light-emitting device, the structure of the device is:

[0033] ITO / HAT-CN(100nm) / NPB(15nm) / TCTA(5nm) / TCTA: FIrpic(10nm, 8%) / 26DCzPPy: FIrpic(10nm, 20%) / PO-01(0.5nm) / TmPyPB(15nm ) / Bepp 2 : KBH4(10nm, 15%) / HAT-CN(100nm) / NPB(15nm) / TCTA(5nm) / TCTA: FIrpic(10nm, 8%) / 26DCzPPy: FIrpic(10nm, 20%) / PO-01( 0.5nm) / / TmPyPB(50nm) / Cs 2 CO 3 (1nm) / Al(200nm).

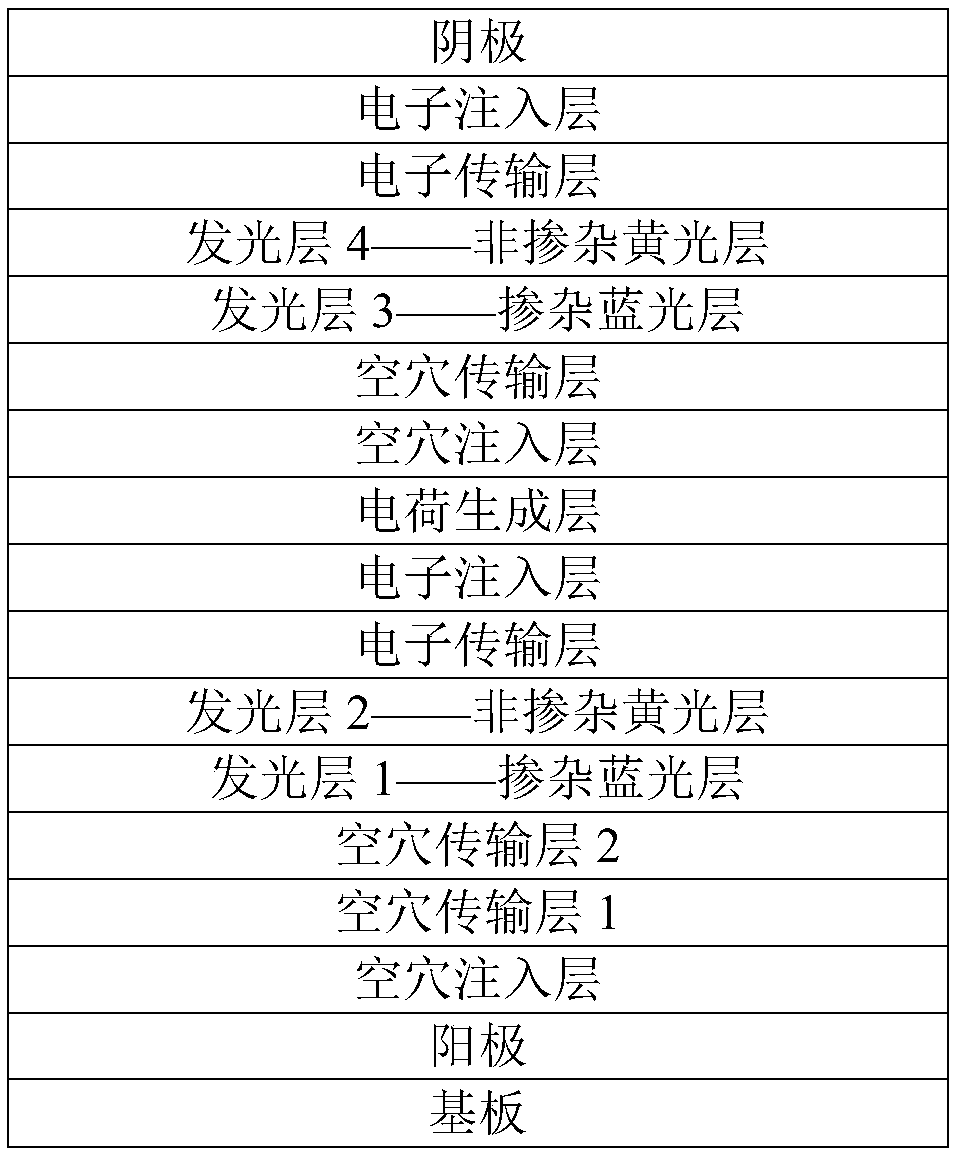

[0034] The structure of the device is as figure 1 Said, it is stacked by the following layers in sequence: substrate, anode, hole injection layer, hole transport layer 1, hole transport layer 2, doped blue layer, non-doped yellow light layer, electron transport layer, electron injection layer , Charge generation layer, hole injection layer, hole transport layer, doped blue light layer, non-doped yellow light layer, electron transport layer, electron injection layer, cathode.

[0035] Perform performance testing on the finished device of Example 1 obtained in this example, and the efficiency diagram is as ...

Embodiment 2

[0037] A white light series organic light-emitting device, the structure of the device is:

[0038] ITO / HAT-CN(100nm) / NPB(15nm) / PO-01(0.5nm) / m-MTDATA(3nm) / TCTA: FIrpic(10nm, 8%) / TmPyPB(15nm) / Bepp2: KBH4(10nm, 15%) / HAT-CN(100nm) / NPB(15nm) / TCTA(5nm) / PO-01(0.5nm) / Bphen(1.5nm) / TCTA: FIrpic(10nm, 8%) / TmPyPB(50nm) / Cs2CO3(1nm) / Al(200nm).

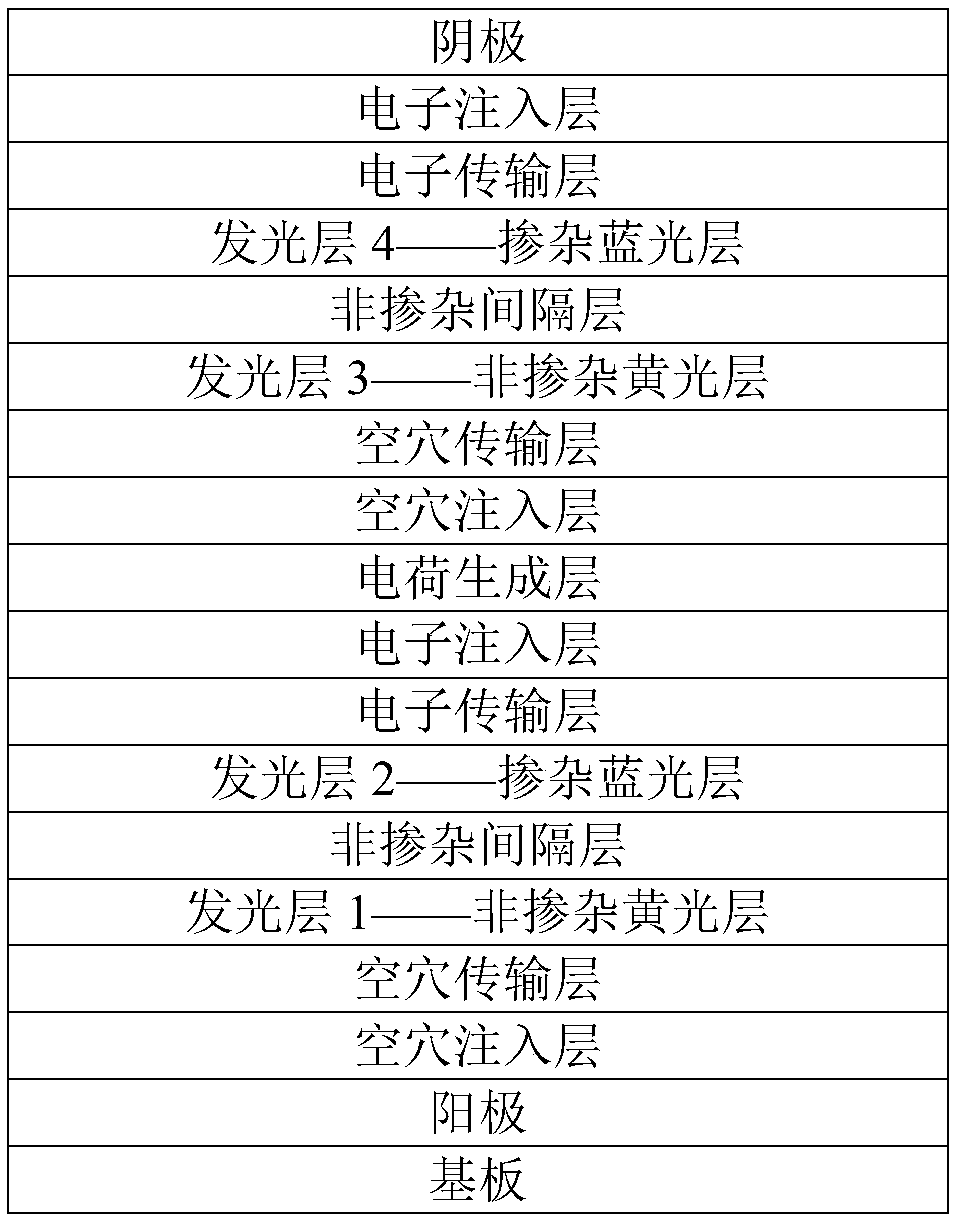

[0039] The structure of the device is as figure 2 Said, it is superimposed by the following layers in sequence: substrate, anode, hole injection layer, hole transport layer, undoped yellow light layer, undoped spacer layer, doped blue light layer, electron transport layer, electron injection layer, Charge generation layer, hole injection layer, hole transport layer, non-doped yellow light layer, non-doped spacer layer, doped blue light layer, electron transport layer, electron injection layer, cathode.

[0040] The performance of the finished device of Example 2 obtained in this example was tested, and its maximum efficiency was measured to be 63.5 cd...

Embodiment 3

[0042] A white light series organic light-emitting device, the structure of the device is:

[0043] ITO / HAT-CN(100nm) / NPB(15nm) / PO-01(0.5nm) / TCTA: FIrpic(10nm, 8%) / TmPyPB(15nm) / Bepp 2 :KBH4(10nm, 15%) / HAT-CN(100nm) / NPB(15nm) / TCTA(5nm) / Ir(piq) 3 (0.3nm) / TCTA: FIrpic(10nm, 8%) / TmPyPB(50nm) / Cs 2 CO 3 (1nm) / Al(200nm).

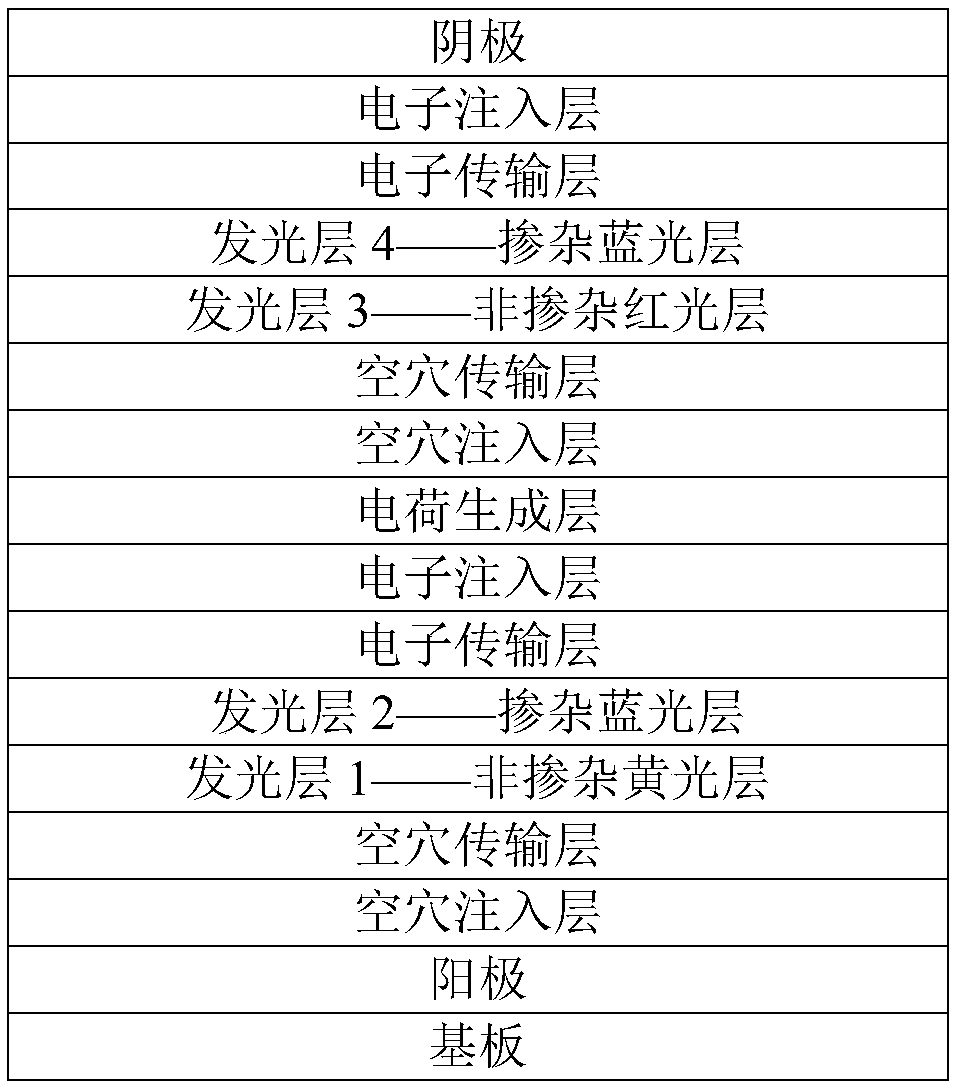

[0044] The structure of the device is as image 3 Said, it consists of the following layers in sequence: substrate, anode, hole injection layer, hole transport layer, non-doped yellow light layer, doped blue layer, electron transport layer, electron injection layer, charge generation layer, hole Injection layer, hole transport layer, non-doped red light layer, doped blue light layer, electron transport layer, electron injection layer, cathode.

[0045] The performance of the finished device of Example 3 obtained in this example was tested, and its maximum efficiency was measured to be 71.8 cd / A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com