Electronegative gas electromigration membrane separation method

A gas separation and gas separation membrane technology, applied in separation methods, gas treatment, dispersed particle separation, etc., can solve the problem that the separation of electronegative gas and non-electronegative gas cannot be achieved, the absorption liquid needs subsequent treatment, and the increase of flue gas can be solved. humidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

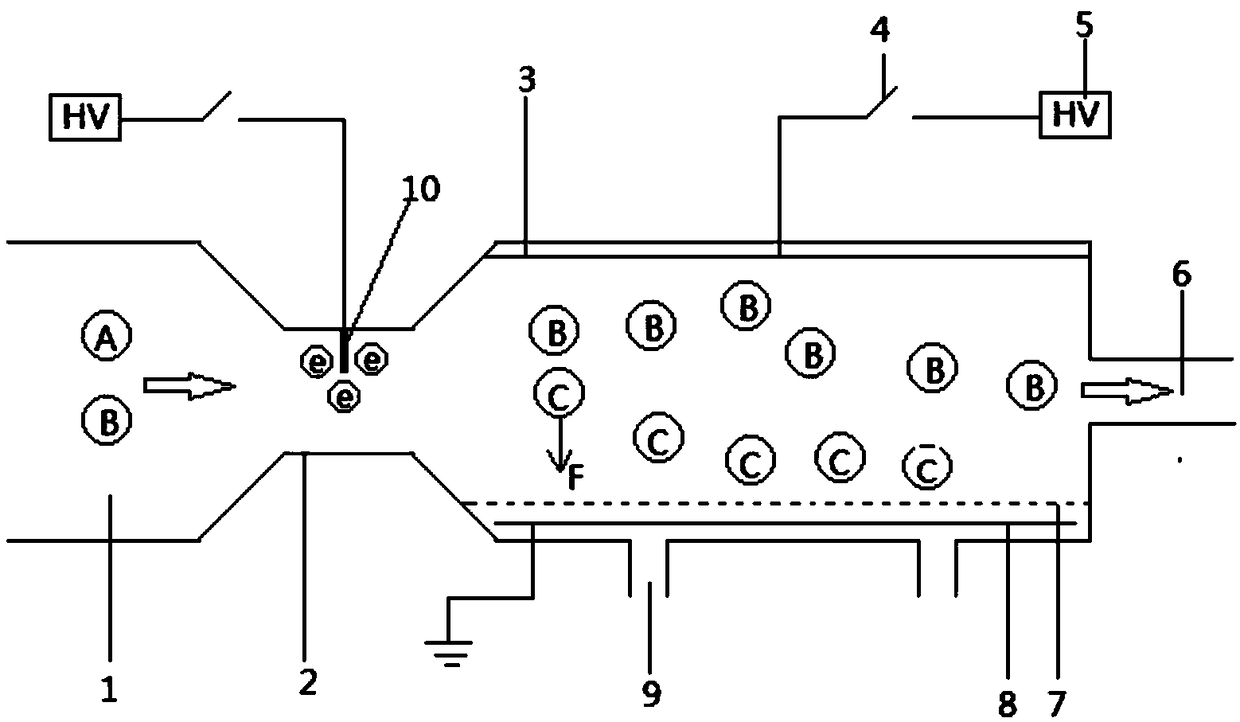

[0024] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 As shown, an electronegative gas electromigration membrane separation method includes the following steps, passing the electronegative and non-electronegative mixed gas to be separated into the gas separation device, and using the electron generator in the gas separation device to generate electrons , the electronegative gas in the mixed gas collides with electrons to generate stable negative ions or negative ion clusters, negative ions or negative ion clusters and uncharged non-electronegative gas enter the gas separation device together with the gas flow formed by the cathode and anode Electric field, a gas separation membrane is provided near the inner side of the anode in the electric field, and the negative ions or negative ion clusters penetrate through the gas separation membrane under the promotion of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com