Energy-saving and environment-friendly rice processing equipment

A technology for rice processing, energy saving and environmental protection, applied in lighting and heating equipment, heating devices, dryers and other directions, can solve the problems affecting the quality of rice processing, poor rice grinding quality, and single equipment function, and achieve good crushing effect. The effect of reducing energy consumption and avoiding excess moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

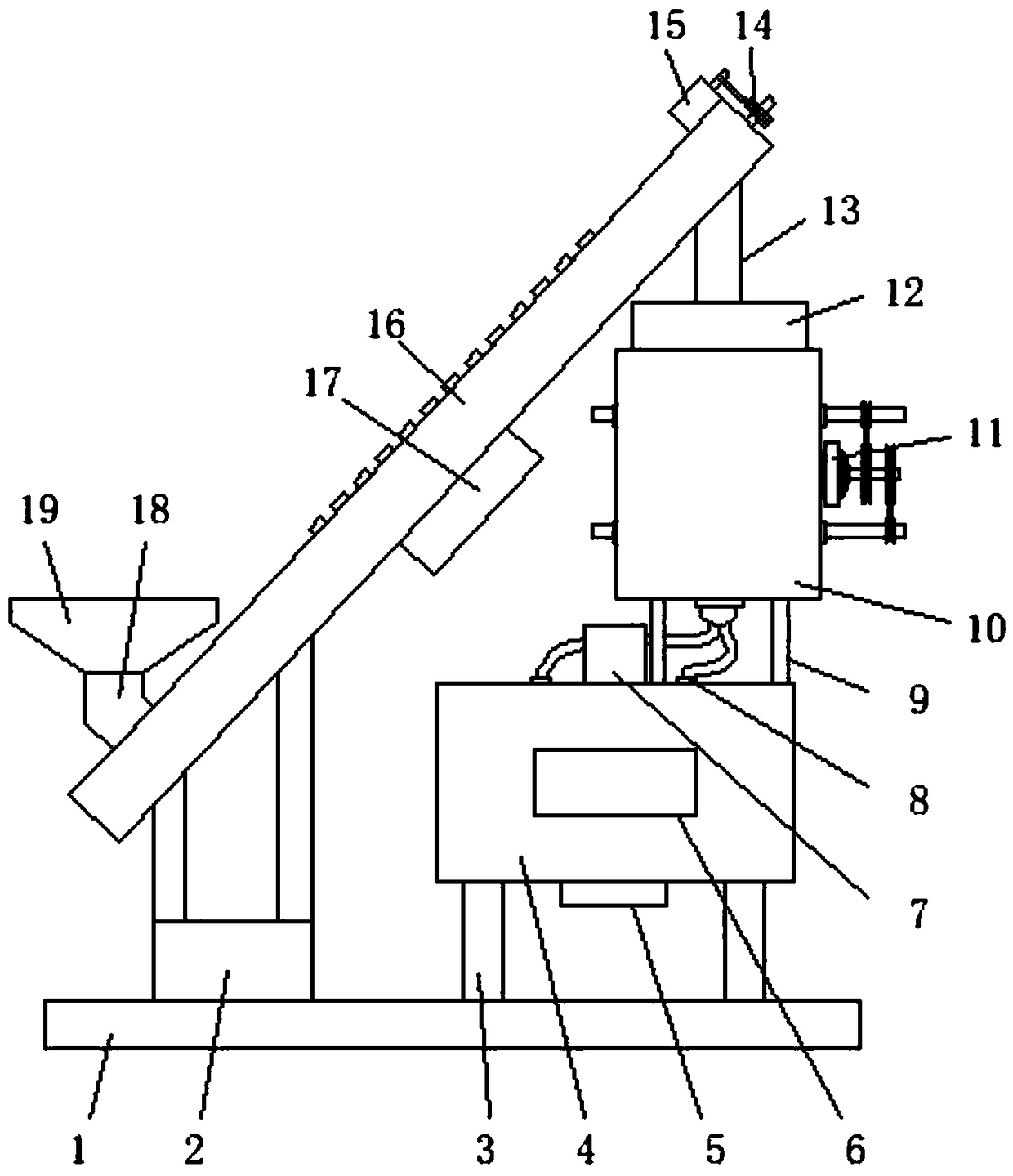

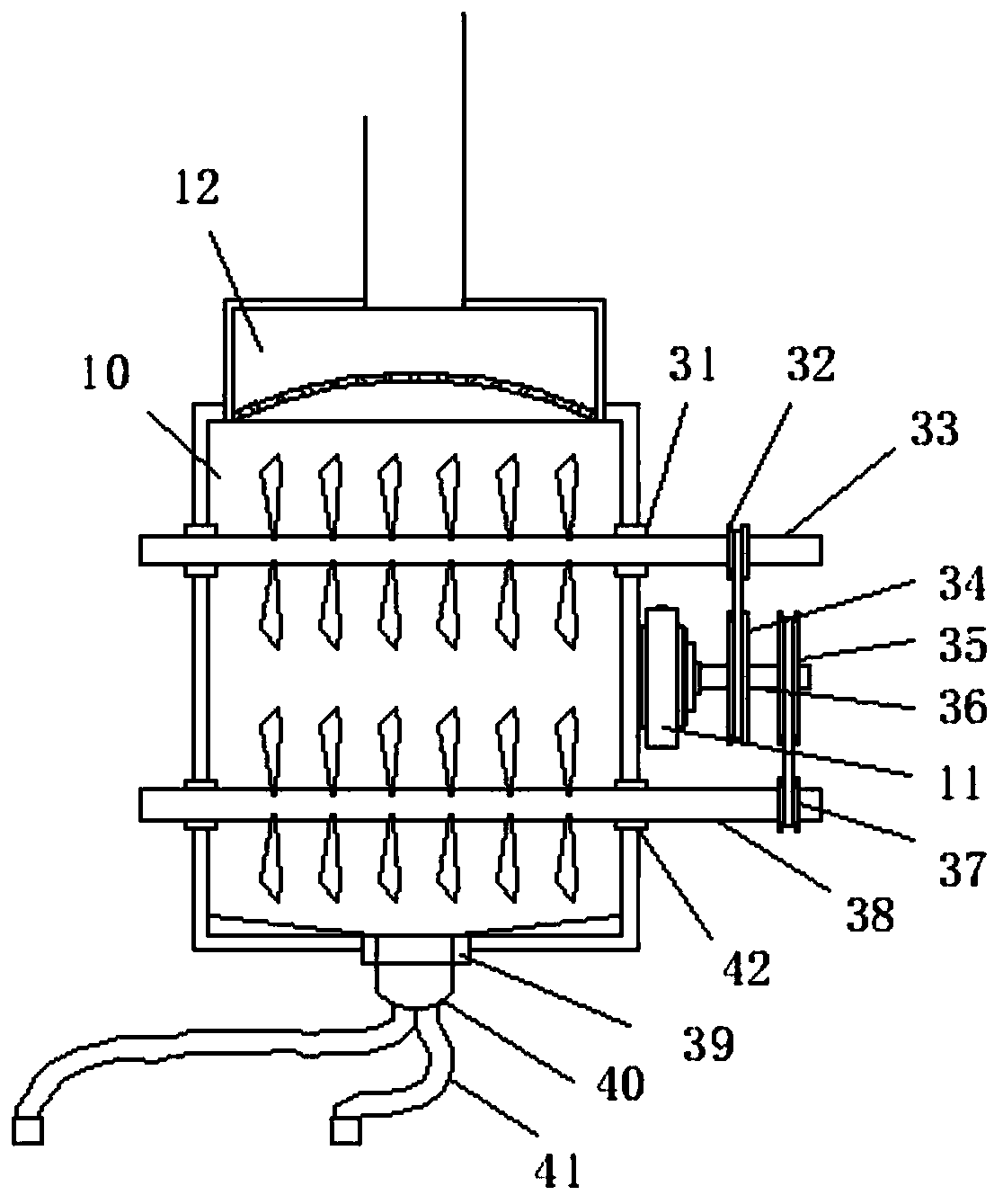

[0029] Example 1, such as Figure 1-3 The pulverizing motor 11 drives the first driven wheel 32 to rotate through the first driving wheel 34, drives the first driving wheel 37 to rotate through the second driving wheel 35, and drives the first driving wheel 37 to rotate, thereby driving the first rotating rod 33 and the second rotating rod 38 Rotate so that the pulverizing blade 25 smashes the rice, the radius of the first driving wheel 34 and the second driving wheel 35 is three times of the radius of the first driven wheel 32 and the first driving wheel 37, thereby the first rotating rod 33 can be improved. and the rotating speed of the second rotating rod 38, improve the efficiency of device smashing, improve the efficiency of device, play the effect of energy saving.

Embodiment 2

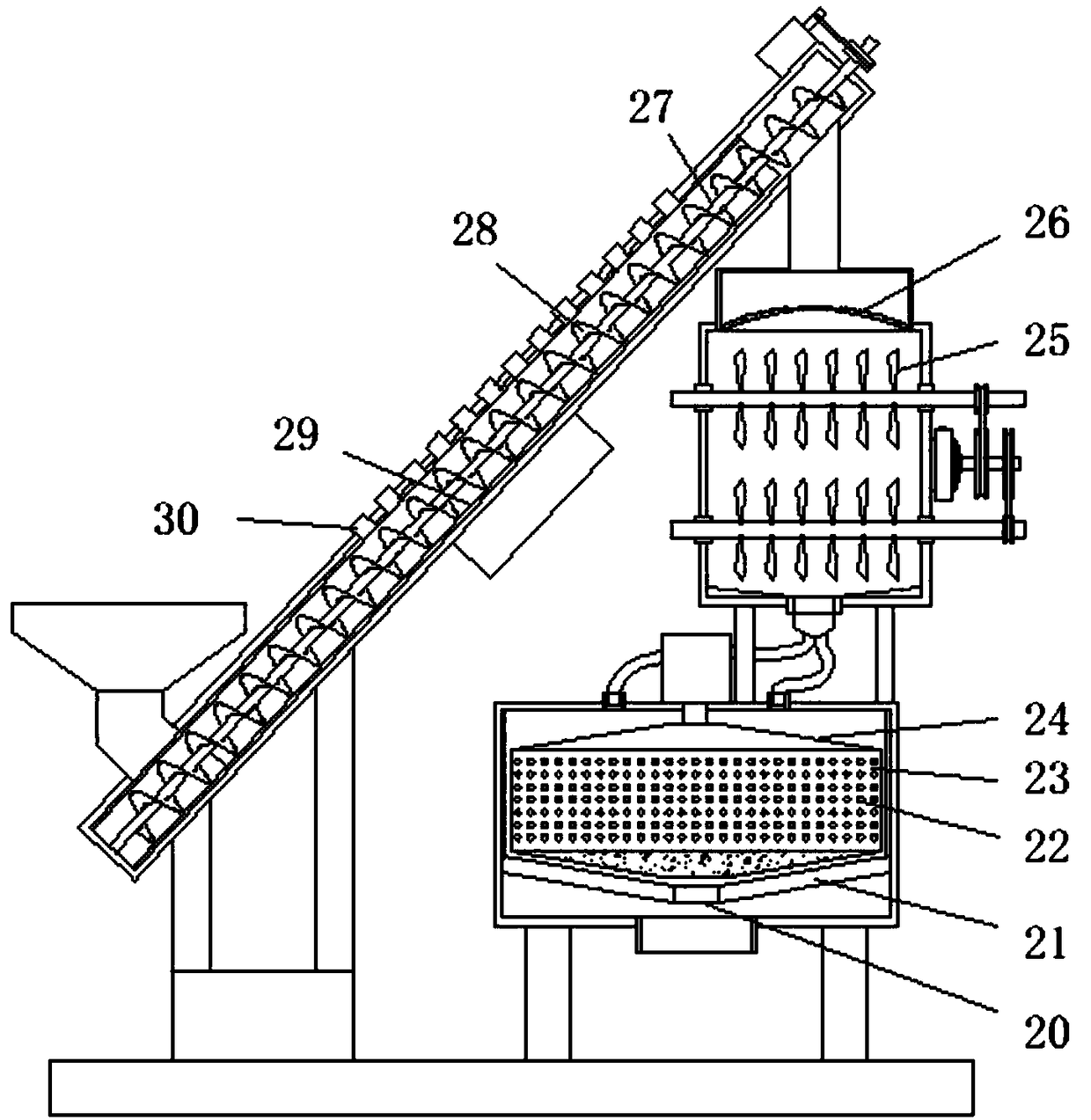

[0030] Example 2, such as figure 1 , 2 , 4,5 When grinding, the rice falls evenly between the grinding disc 23 and the inside of the grinding bin 4 through the blanking plate 24, and is ground by the grinding beads 22 and grinding on the outside of the grinding disc 23, and the preliminary grinding is carried out. The finished rice falls on the top of the grinding plate 21, and the rice is grinded twice by the grinding plate 21 and the grinding disc 23 to improve the grinding effect.

[0031] Working principle: before use, connect the device to the power supply, first put the rice into the inside of the feeding hopper 19, and then turn on the conveying motor 15, crushing motor 11, heater 17 and grinding motor 7 through the control panel 6, so that the conveying motor 15 passes through The belt pulley 14 drives the rotation, thereby driving the spiral blade 28 to rotate, and the rice is transported. At the same time, the heater 17 can be turned on through the control panel 6 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com