Novel synthesis method of 2-butyl-1,2-benzothiazol-3-one

A technology of isothioline and a new method, which is applied in the field of 2-butyl-1,2-benzisothiazolin-3-one synthesis, can solve the problems of poor selectivity, by-product generation, and large amount of three wastes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

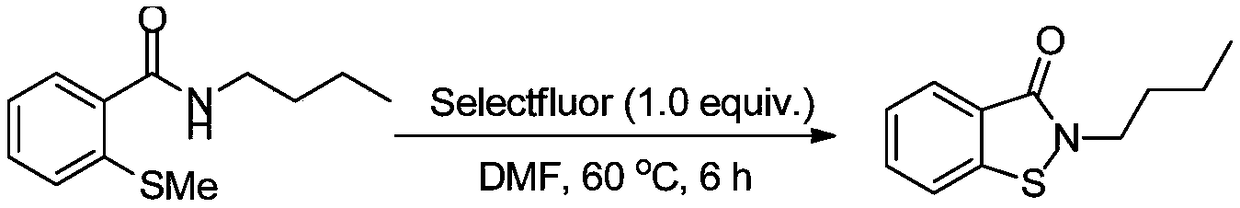

[0010] Add N-butyl-2-methylthiobenzamide (20mmol, 2.23g), 1-chloromethyl-4-fluoro-1,4-diazabicyclo[2.2. 2] Octane bis(tetrafluoroborate) salt (20mmol, 3.55g) and 20mL of N,N-dimethylformamide, the reaction temperature was controlled at 60°C, and the reaction was vigorously stirred for 6h. After the reaction, cool to room temperature, wash the reaction system with water, extract, distill the filtrate under reduced pressure, and collect the main fraction to obtain 2-butyl-1,2-benzisothiazolin-3-one (3.80g, 92%).

[0011] The equations involved in the reaction are as follows:

[0012]

specific Embodiment 2

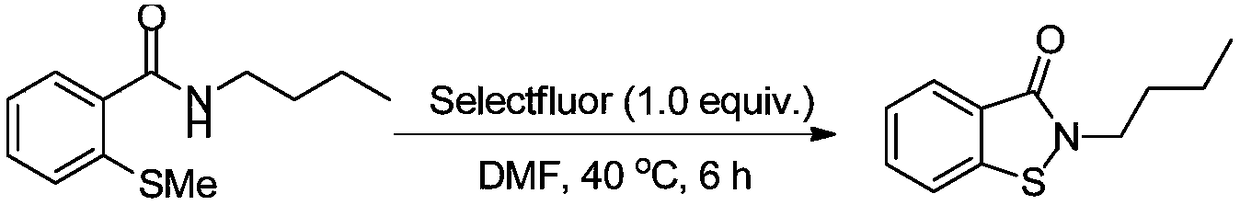

[0013] Add N-butyl-2-methylthiobenzamide (20mmol, 4.46g), 1-chloromethyl-4-fluoro-1,4-diazabicyclo[2.2. 2] Octane bis(tetrafluoroborate) salt (20mmol, 7.10g) and 20mL of N,N-dimethylformamide, the reaction temperature was controlled at 40°C, and the reaction was vigorously stirred for 6h. After the reaction, cool to room temperature, wash the reaction system with water, extract, distill the filtrate under reduced pressure, and collect the main fraction to obtain 2-butyl-1,2-benzisothiazolin-3-one (3.40g, 82%).

[0014]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com