Synthesis technology of ethylene sulfate

A technology of vinyl sulfate and synthesis process, applied in the direction of organic chemistry, etc., can solve the problems of difficult treatment, large amount of waste water, etc., and achieve the effects of low production cost, less three wastes, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

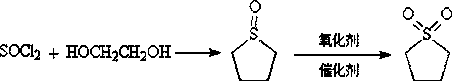

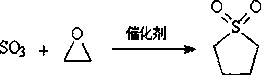

Method used

Image

Examples

Embodiment 1

[0027] Add 62g (1mol) of ethylene glycol, 242g (2mol) of dimethylaniline, and 1000mL of chloroform into the reaction flask, cool the temperature to -10°C, add 135g (1mol) of sulfuryl chloride dropwise under stirring, and control the temperature not to exceed 0 ℃. After the dropwise addition was completed, the reaction was incubated for 1 hour. The dimethylaniline hydrochloride produced by filtration, the mother liquor was washed with deionized water to neutrality, after drying with anhydrous sodium sulfate, the solvent was evaporated to dryness to obtain 101 g of a light yellow solid, which was recrystallized with dichloromethane to obtain 94 g of a white product, passed The product was analyzed by liquid chromatography to be vinyl sulfate, and the yield was 75.8%. Melting point: 95-97°C. GC analysis purity: 99.5%.

Embodiment 2

[0029] Add 62g (1mol) of ethylene glycol, 222g (2.2mol) of triethylamine, and 1000mL of dichloromethane into the reaction flask, cool the temperature to -10°C, add 135g (1mol) of sulfuryl chloride dropwise under stirring, and control the temperature not to exceed 0 ℃. After the dropwise addition was completed, the reaction was incubated for 1 hour. The produced triethylamine hydrochloride was filtered, the mother liquor was washed with deionized water until neutral, dried with anhydrous sodium sulfate, and the solvent was evaporated to dryness to obtain 87 g of light yellow solid. Recrystallization with dichloromethane gave 78g of white product. The product was analyzed by liquid chromatography to be vinyl sulfate, and the yield was 63%. Melting point: 95-97°C. GC analysis purity: 99.48%.

Embodiment 3

[0031] Add 62g (1mol) of ethylene glycol, 200g (2.5mol) of pyridine, and 1000mL of dichloroethane into the reaction flask, cool the temperature to -10°C, add 135g (1mol) of sulfuryl chloride dropwise under stirring, and control the temperature not to exceed 0°C . After the dropwise addition was completed, the reaction was incubated for 1 hour. The generated pyridine hydrochloride was filtered, the mother liquor was washed with deionized water until neutral, dried with anhydrous sodium sulfate, and the solvent was evaporated to dryness to obtain 97 g of light yellow solid. Recrystallization with dichloromethane gave 87g of white product. The product was analyzed by liquid chromatography to be vinyl sulfate, and the yield was 70.2%. Melting point: 95-97°C. GC analysis purity: 99.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com