Method for preparing high-quality biological polysaccharide

A technology of mass percentage content and xanthan gum, which is applied in the field of purification of xanthan gum coarse powder, can solve the problems of destroying product properties, reducing product recovery rate, etc., achieving low cost, fewer production process steps, and simple and easy technical operation The effect of mastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

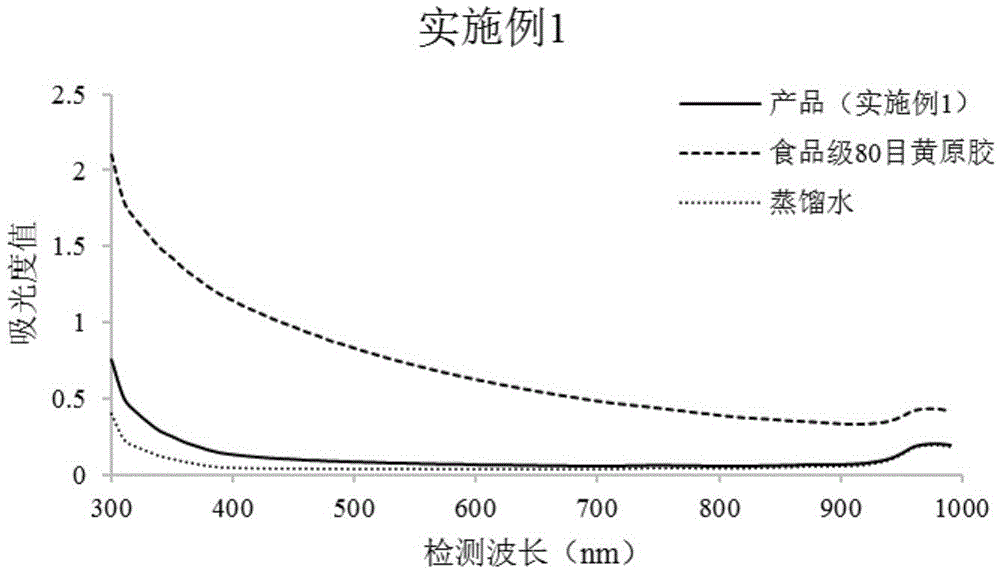

Embodiment 1

[0050]1. Preparation of xanthan collagen sample solution: Mix Fufeng food grade 80 mesh xanthan gum powder with 10 times the weight of glucose powder evenly, add a small amount of high-speed stirring distilled water at 90°C one by one, continue stirring until fully dissolved, and prepare the quality A xanthan collagen-like solution with a percentage content of 0.25%, and cooled to about 37° C. for use.

[0051] 2. Lipase enzymatically removes impurities: dissolve Solarbio lipase (L8070, enzyme activity 100-400U / mg) in physiological phosphate buffer, add the lipase solution to the 0.25 % xanthan collagen-like solution. Afterwards, the mixture was stirred and mixed at 37°C for 30 minutes, and left at 37°C for 12 hours for enzymatic hydrolysis.

[0052] 3. Enzyme inactivation: heating the xanthan gum solution after the enzymolysis treatment in step 2 in a boiling water bath to inactivate lipase.

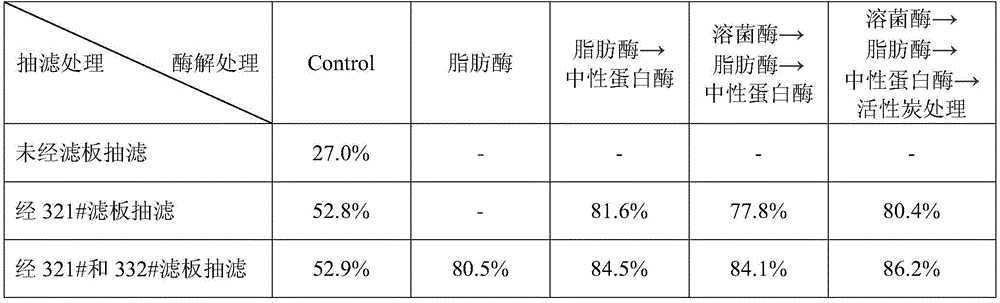

[0053] 4. Vacuum suction filtration: according to 311# (clarifying filter cardboa...

Embodiment 2

[0061] 1. Preparation of xanthan collagen sample solution: add Fufeng food grade 200-mesh xanthan gum powder into distilled water at 90°C with high-speed stirring in small amounts until fully dissolved, and prepare a xanthan collagen sample with a mass percentage of 0.25%. solution and cooled to about 40°C for later use.

[0062] 2. Lipase enzymatically removes impurities: dissolve Solarbio lipase (L8070, enzyme activity 100-400U / mg) in physiological phosphate buffer, add the lipase solution to the 0.25 % xanthan collagen-like solution. Afterwards, the mixture was continuously stirred at 40° C. for 2 h to carry out enzymatic hydrolysis.

[0063] 3. Enzyme inactivation: heat the xanthan gum solution after enzymolysis in step 2 in a water bath at 90°C to inactivate the enzyme.

[0064] 4. Vacuum suction filtration: in the order of 311# (pore size 10 μm) → 321# (pore size 1.5 μm) → 332# (pore size 0.8 μm) → 334# (pore size 0.45 μm), use the filter plate to inactivate the enzyme...

Embodiment 3

[0071] 1. Preparation of xanthan collagen sample solution: add Fufeng food grade 200 mesh xanthan gum powder into distilled water and stir evenly, and heat to 80°C to fully dissolve it, and prepare xanthan collagen with a mass percentage of 0.50% The sample solution was cooled to about 40°C for later use.

[0072] 2. Activated carbon adsorption and impurity removal: Add activated carbon with a volume percentage of about 2% to the 0.50% xanthan collagen-like solution prepared in step 1, stir well, and absorb at 4°C overnight, use 300-mesh filter cloth and 311# (pore size 10 μm) filter plate vacuum filtration to remove activated carbon.

[0073] 3. Lysozyme enzyme decontamination: Dissolve Solarbio lysozyme (L8020, enzyme activity >20000U / mg) in physiological phosphate buffer, add lysozyme solution according to the enzyme dosage of 5000U / ml, and remove it by activated carbon adsorption in step 2 in the mixed xanthan gum solution. Afterwards, the mixture was continuously stirre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com