Anti-blue-ray quantum dot membrane and preparation method thereof

A quantum dot film and anti-blue light technology, which is applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problems of discounted anti-blue light effect, yellowish screen, and difficulty in distinguishing the wavelength of blue light sources, etc., to achieve high light Stability and sensitivity, simple preparation method, and high anti-blue light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

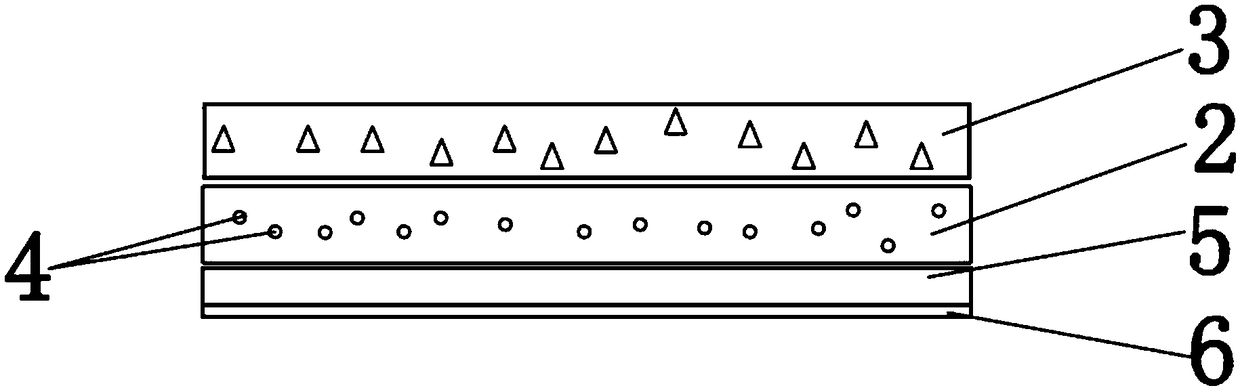

[0070] The anti-blue light quantum dot film is produced by the above steps, wherein the ratio of green quantum dots to red quantum dots is 50:1, the organic solvent is cyclohexane, the material of the light conversion layer is PMMA, the concentration of quantum dots is 0.01%, and the protective film material is selected for Al 2 o 3 + PET.

Embodiment 2

[0072] The anti-blue light quantum dot film is produced by the above steps, wherein the ratio of green quantum dots to red quantum dots is 50:1, the organic solvent is n-hexane, the material of the light conversion layer is PET, the concentration of quantum dots is 0.02%, and the protective film material is selected as SiC+PVC.

Embodiment 3

[0074] The anti-blue quantum dot film is produced by the above steps, wherein the ratio of green quantum dots to red quantum dots is 50:1, the organic solvent is 1-octadecene, the material of the light conversion layer is PS, the concentration of quantum dots is 0.03%, and the protective film Material selection is SiO 2 +PP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com