Computerized flat machine yarn nozzle running assembly

A computerized flat knitting machine and yarn feeder technology, which is used in textile and papermaking, weft knitting, knitting and other directions, can solve the problem that the yarn feeder handle cannot be raised and lowered, and achieves rich pattern design, efficient weaving efficiency, and improved weaving. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

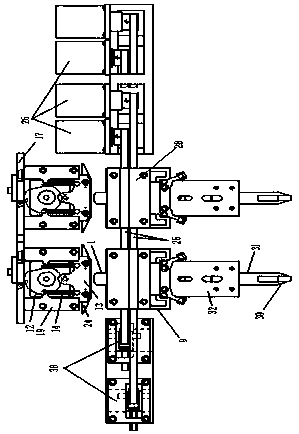

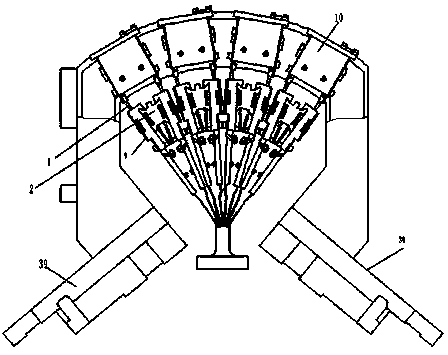

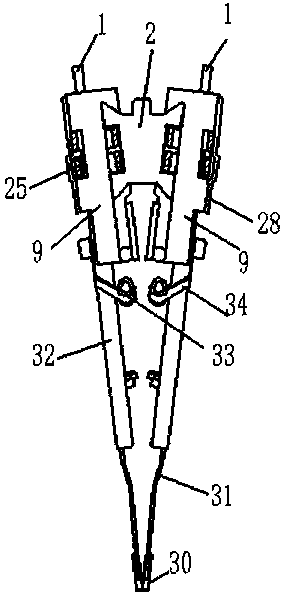

[0041] Computerized flat knitting machine yarn feeder running assembly, such as Figure 1-13 As shown, it includes a flyover, a shuttle rail seat, three or four shuttle rails 2 installed on the shuttle rail seats on both sides, the shuttle rail 2 is distributed in an arc shape, and the yarn feeder seat 9 slidably installed on the shuttle rail 2 is also in a corresponding shape. arc distribution.

[0042] Yarn carrier seat 9 comprises yarn carrier seat body 36 and inclined guide block 37, forms dovetail groove between yarn carrier seat body 36 and inclined guide block 37, and the angle of this dovetail groove coincides with the acute angle of four sides of shuttle rail 2, ensures The yarn carrier seat 9 can slide smoothly along the length direction of the shuttle rail 2. Yarn feeder seat body 36 has stage clip to top press inclined guide block 37, and yarn feeder seat body 36, inclined guide block 37 contact with shuttle rail 2 sides all the time, make shuttle rail 2 and yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com