3D printing device boom system and debugging method

A 3D printing and jib technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of reduced printing accuracy and large deflection, and achieve the effect of small deflection and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

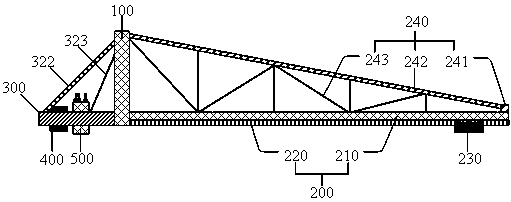

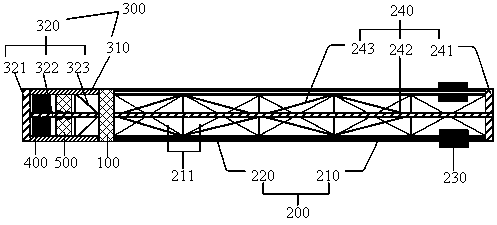

[0057] see Figure 1 to Figure 3 , the present invention provides a 3D printing device arm frame system, including a vertically arranged door frame 100, a boom frame 200 and a balance arm frame 300 respectively arranged on both sides of the door frame 100, and a balance arm frame 300 arranged on the The standard counterweight assembly 400 on, and the hydronic balance assembly 500.

[0058] Wherein, the boom frame 200 includes a boom beam 210, a guide rail 220 arranged below the boom beam 210, and a horizontal drive braking device for the print head that can move horizontally along the guide rail 220 is provided on the guide rail 220. 230. combine figure 1 and figure 2 As shown, the boom beams 210 are two groups parallel to each other, the two groups of boom beams 210 are fixedly connected by a plurality of reinforcing rods 211 , and the boom beams 210 are formed into a stable whole by a plurality of reinforcing rods 211 . The boom frame 200 also includes an upper arm fram...

Embodiment 2

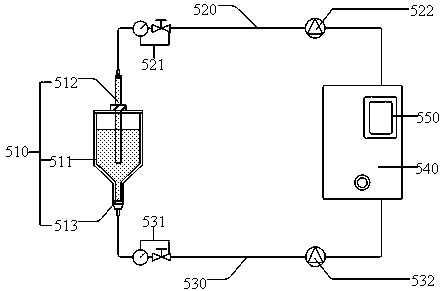

[0068] When printing the main structure of a 3D building, such as a 1m×1m support column, the diameter of the 3D printing head may reach 30cm or more, and the weight of the 3D printing head is relatively heavy. When the 3D printing head runs along the guide rail 220, the boom frame 200 The change of the torque above is relatively large, and the inflow flow control valve 521 / outflow flow control valve 531 needs a large adjustment range. When printing auxiliary structures on the wall, it is possible to replace it with a print head with a diameter of 3 cm. The weight of the 3D print head is small, and the moment change on the boom frame 200 is small when running along the guide rail 220, and the flow into the flow control valve 521 / The outflow flow control valve 531 requires a smaller adjustment range and higher adjustment accuracy.

[0069] For this, as Figure 4 As shown, in the 3D printing device arm support system provided in this embodiment, the liquid circulation balance ...

Embodiment 3

[0071] The present invention also provides a debugging method for the arm support system of the 3D printing device as in Embodiment 1, the following will be combined with the attached Figures 1 to 4 This debugging method is further introduced. This debugging method includes:

[0072] Step 1: Determine the mass of the standard counterweight assembly 400 through static load calculation m 1 . In the case that the printing head horizontal drive braking device 230 is located at the end of the guide rail 220 close to the door frame 100 and the 3D printing head is installed, according to the moment balance on the boom frame 200 and the balance arm frame 300 and the distance between the standard counterweight assembly 400 and the door frame A distance of 100 determines the mass of the standard counterweight assembly 400 m 1 . From Example 1, it can be seen that . A standard weight assembly 400 can include a plurality of weights with a total mass of m 1 , The position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com