Method for preventing bottom water onrushing of oilfield

A bottom water and oil field technology, applied in the field of applied chemistry, can solve the problems of short validity period, poor effect, high oil-water two-phase permeability, etc., and achieve the effect of reducing permeability and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Optionally, wherein, the preparation method of the nanoparticles includes: adding the aqueous solution of the polymerized monomer to the oil phase medium to obtain a polymerization reaction system and performing visible light photosensitized polymerization to obtain a polymerized product, and then dispersing the polymerized product in the Reinjection into water: the polymerized monomer includes acrylamide and modified monomer, and the oil phase medium includes solvent oil, surfactant and visible light initiator.

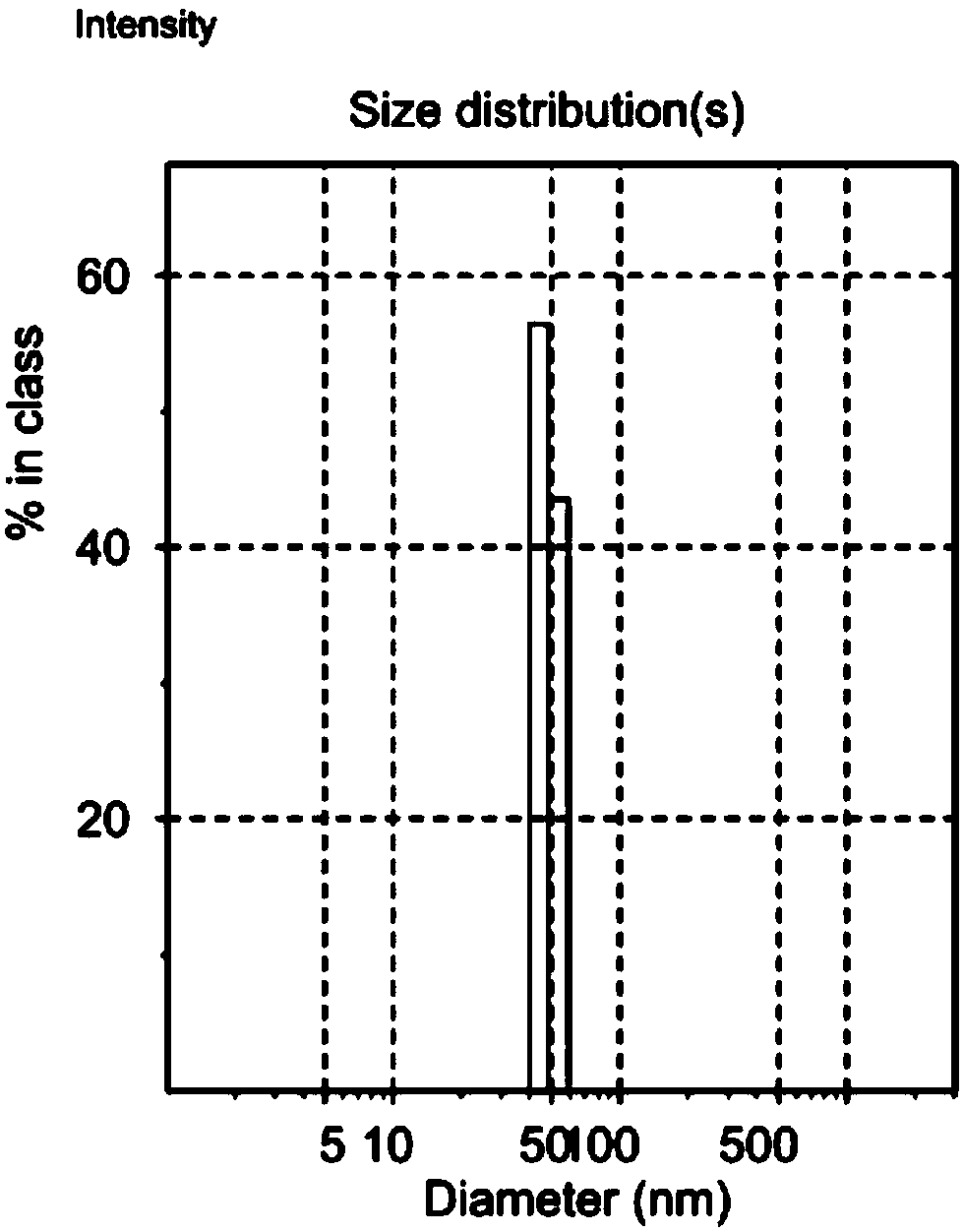

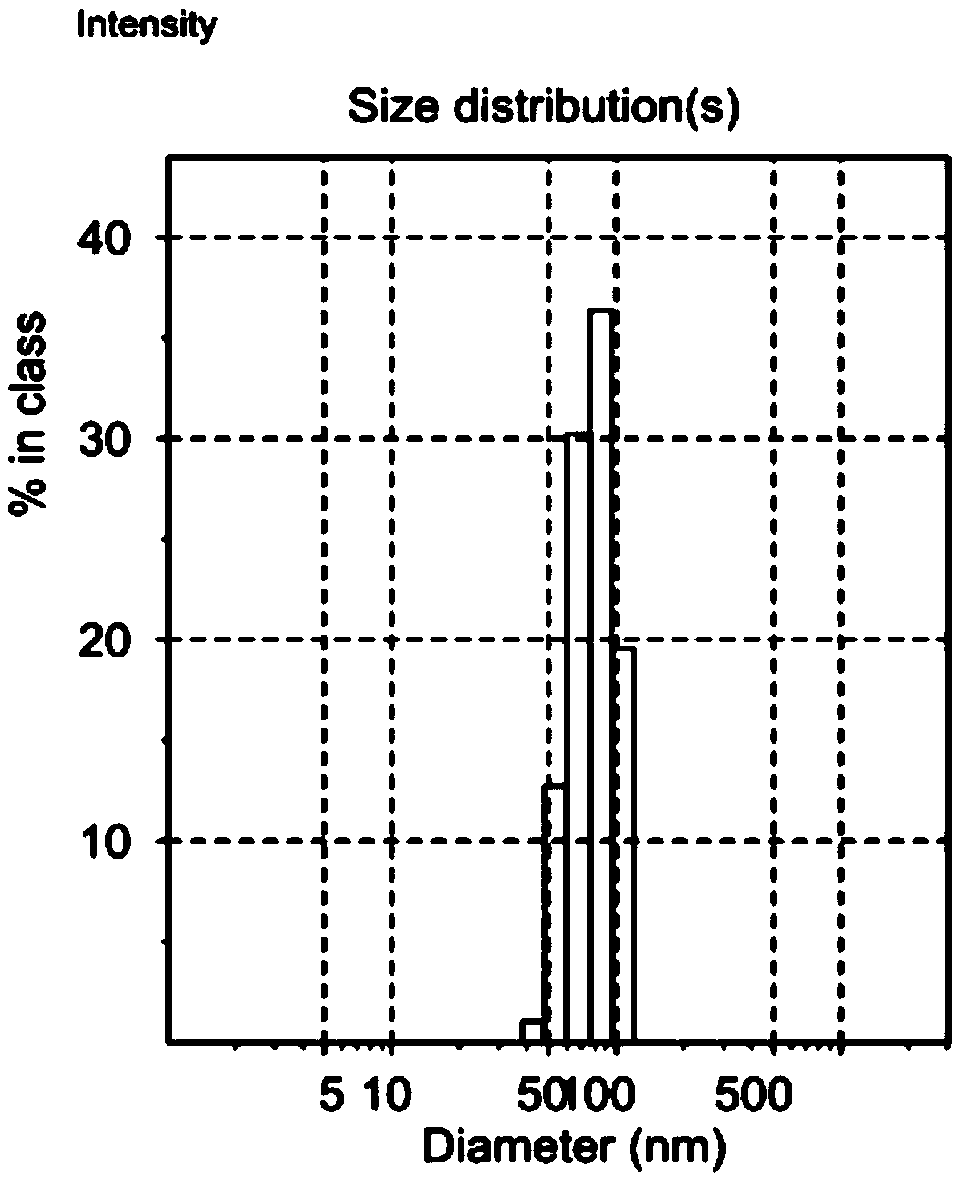

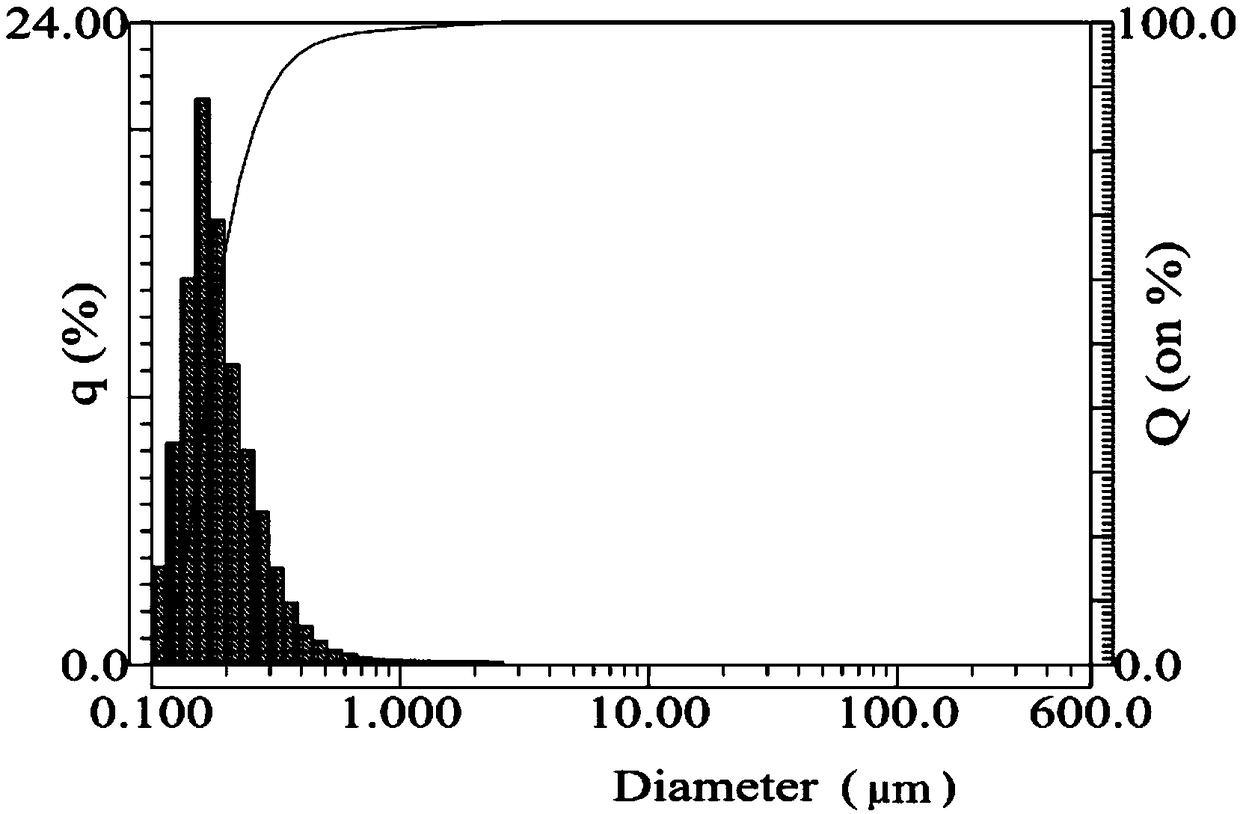

[0031] Among them, visible light photosensitized polymerization is relatively easy to control the reaction speed, which is the reason why the nanoparticles can have a suitable particle size of 10 nm to 300 nm. Wherein, the surface of the nanoparticles in the reinjection water is charged and has a smaller particle size after swelling, so it can maintain stable dispersion in the reinjection water without stratification.

[0032] Optionally, wherein the polymeriz...

Embodiment 1

[0039] The oil reservoir is located in an ordinary waterflooding oilfield, its geological conditions are lacustrine, fluvial or delta sedimentary sandstone, the reservoir is flat, the mineral deposit conditions are temperature 25-70 ℃, pH=7.0-7.8, and total salinity 1000-36000mg / L, the total amount of calcium and magnesium ions is 15-1500mg / L, the average permeability is 1800mD, and the viscosity of crude oil in the oil reservoir is 1-50cP. Significant bottom water outburst occurred in this reservoir.

[0040] According to the reservoir conditions, the most preferred synthetic formula of nanoparticles in the reinjected water is: water phase composition, water 28g, acrylamide 20g, acrylic acid 0.5g, p-vinylbenzenesulfonic acid 1g, AMPSNa5g, N,N '-Methylenebisacrylamide 200mg, pentaerythritol acrylate 5mg, neutralized with 5% NaOH aqueous solution to pH=7.0; oil phase composition: No. 7 white oil 16g, aliphatic sorbitan ester 8g, polyoxyethylene Sorbitan fatty ester 1g, fatty ...

Embodiment 2

[0044] The oil reservoir is located in an ordinary water injection development oilfield, its geological conditions are lacustrine, fluvial or delta sedimentary sandstone, the reservoir is flat, the mineral deposit conditions are temperature 25-70 ℃, pH=7.8-8.2, and the total salinity is 1000-36000mg / L, the total amount of calcium and magnesium ions is 15-1500mg / L, the average permeability is 1800mD, and the viscosity of crude oil in the oil reservoir is 1-50cP. Significant bottom water outburst occurred in this reservoir.

[0045] According to this reservoir condition, the most preferred synthetic formula of nanoparticles in the reinjected water is: water phase composition, water 28g, acrylamide 16g, acrylic acid 0.5g, p-vinylbenzenesulfonic acid 2g, AMPSNa7g, N,N 200 mg of '-methylenebisacrylamide, 5 mg of pentaerythritol acrylate, neutralized with 5% NaOH aqueous solution to pH = 7.0; oil phase composition: 16 g of No. 7 white oil, 8 g of aliphatic sorbitan ester, polyoxyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com