High-strength reinforced concrete segment for tunnel support and production method thereof

A technology of reinforced concrete and concrete, which is applied in the direction of earthwork drilling, tunnel, tunnel lining, etc., can solve problems such as the support requirements of unfavorable geological tunnel sections, and achieve the effect of long-term stable reduction, performance improvement, and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment the present invention is described in further detail:

[0016] For the high-strength reinforced concrete segment for tunnel support of the present invention, 35kg-40kg of inorganic nanomaterials and 6kg-8kg of polypropylene crude fiber are added to each cubic meter of concrete in the production of segment raw materials referring to C45, C50, and C55 conventional high-strength concrete;

[0017] Inorganic nanomaterial indicators and polypropylene crude fiber indicators are as follows:

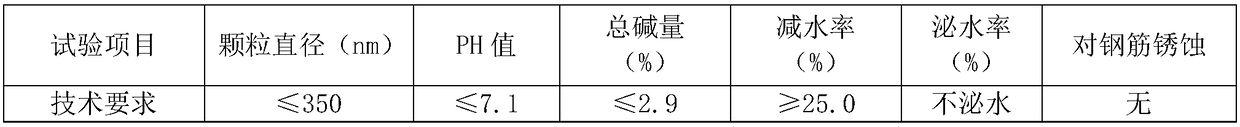

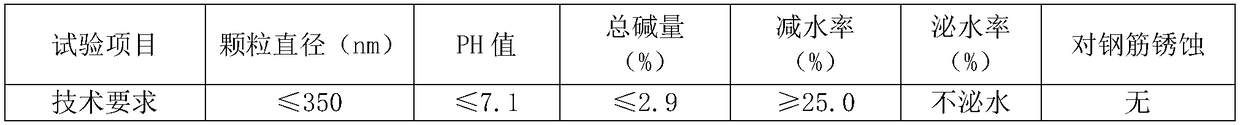

[0018] Inorganic Nanomaterial Index Table

[0019]

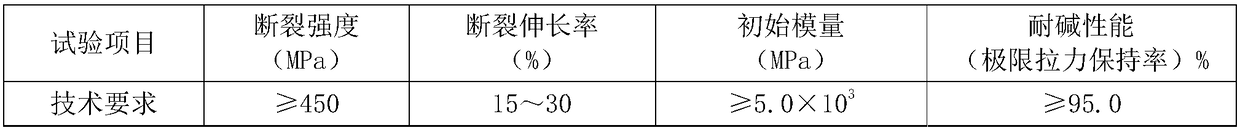

[0020] Polypropylene Crude Fiber Index Table

[0021]

[0022] The production method of the above-mentioned high-strength reinforced concrete segment for tunnel support comprises the following steps:

[0023] (1) Testing and testing of composite materials: Inorganic nanomaterials and polypropylene crude fibers added in segment production, the indicators of the two materials are teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com