Anti-scale water cooling bearing bush

A water-cooled bearing and bearing pad technology, which is applied to bearing components, shafts and bearings, bearing cooling, etc., can solve the problem of easy scaling of cooling water channels, achieve strong anti-scaling ability of water channels, simple structure, easy disassembly, cleaning and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

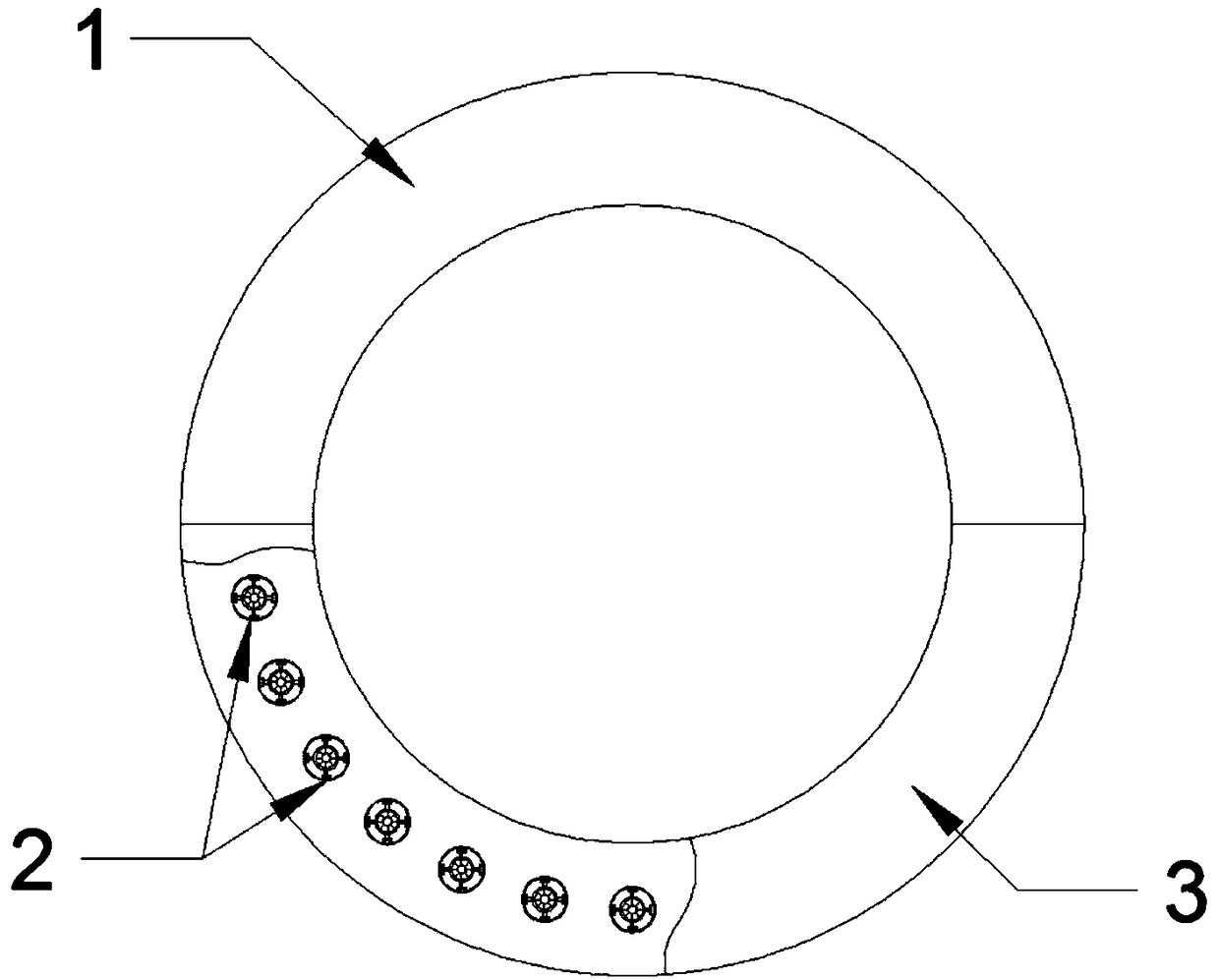

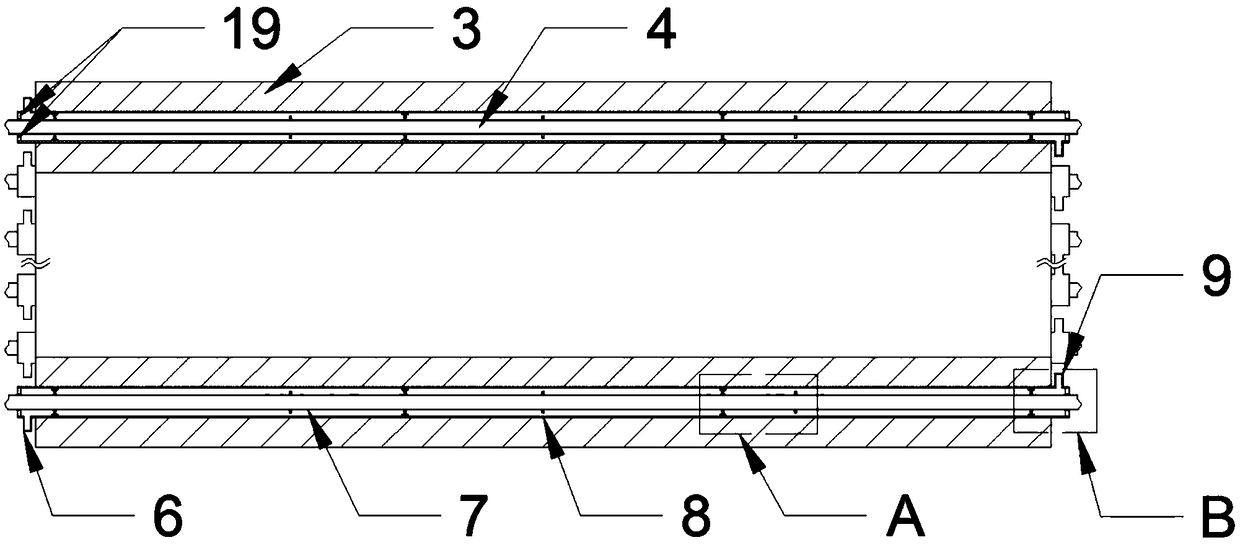

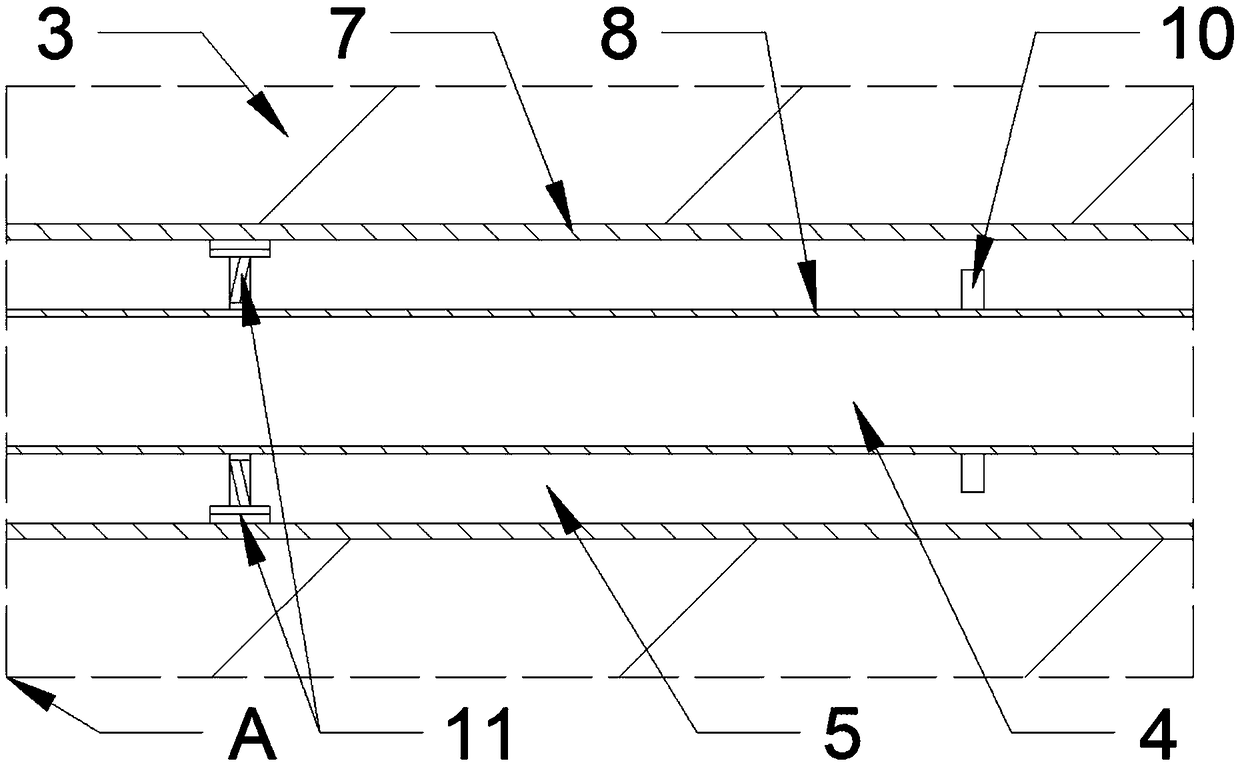

[0034] Such as Figure 1~4 , an anti-scaling water-cooled bearing pad, including an upper bearing pad 1 and a lower bearing pad 3 fixedly connected to each other; the inside of the lower bearing pad 3 is provided with several water-cooling through holes 2; each of the water-cooling through-holes 2 Both are equipped with water-cooling tubes; the water-cooling tubes include a water-cooling outer tube 8 whose outer wall is in contact with the inner wall of the water-cooling through hole 2 and whose two ends extend to the outside of the water-cooling through-hole 2, and which are arranged in the water-cooling outer tube 8 and whose two ends extend to the water-cooling outer tube 8. The water-cooled inner tube 7 outside the tube 8; a sealing body 19 is arranged between the inner wall at both ends of the water-cooled outer tube 8 and the outer wall of the water-cooled inner tube 7, so that the water-cooled outer tube 8 and the water-cooled inner tube 7 are tightly sealed and sealed. ...

Embodiment 2

[0041] Based on Example 1, such as figure 2 and 3 , in order to prevent possible metal salts from being adsorbed and deposited on the walls of the first channel 5, the following improvements are made: at least two spoiler rings 10 are evenly distributed on the outer wall of the water-cooled inner tube 7; the spoiler rings Form gap fit between 10 and water-cooled outer tube 8. By setting the turbulence ring 10, the cooling water flowing through the first channel 5 is in a slightly turbulent state. In this case, even if the cooling water in the first flow channel 5 is insufficiently cooled locally, for example, the cooling water near the inner wall of the water-cooled appearance will be cooled by the water-cooled inner tube 7 weaker than the cooling water near the outer wall of the water-cooled inner tube 7, and a small amount of water will appear. The precipitation of calcium and magnesium ions into salt. The formed inorganic salt particles are not easily attached to the wa...

Embodiment 3

[0043] Based on Example 2, in order to prevent the corrosion of the pipe wall near the first flow channel 5 from forming defects that are conducive to the adsorption of metal salts, the following improvements are made: the outer wall of the spoiler ring 10 is coated with a metal magnesium layer. Since both sides of the water-cooled inner tube 7 are in contact with water and are in a heated state for a long time, they are easily corroded and pits are formed on the surface. By adding a metal magnesium layer on the spoiler ring 10, a primary battery is formed between it and the metal material of the water-cooled inner tube 7, and the electrolysis of the magnesium layer replaces the electrolysis of the water-cooled inner tube 7, thereby preventing the water-cooled inner tube 7 Corrosion avoids the formation of surface pits, thereby reducing the possibility of nucleation of calcium and magnesium inorganic salts precipitated in high-temperature cooling water, and avoiding the accumul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com