Aero-engine time lag-containing non-determinacy fuzzy dynamic model modeling method

An aero-engine and uncertainty technology, which is applied in the modeling of aero-engine dynamic models and uncertain fuzzy dynamic model modeling of aero-engines with time-delay, can solve problems such as complexity and uncertainty, and achieve increased The effect of model dynamic information, improving calculation speed and real-time performance, and avoiding a large number of iterative solution processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The concrete realization of this embodiment is described in detail below:

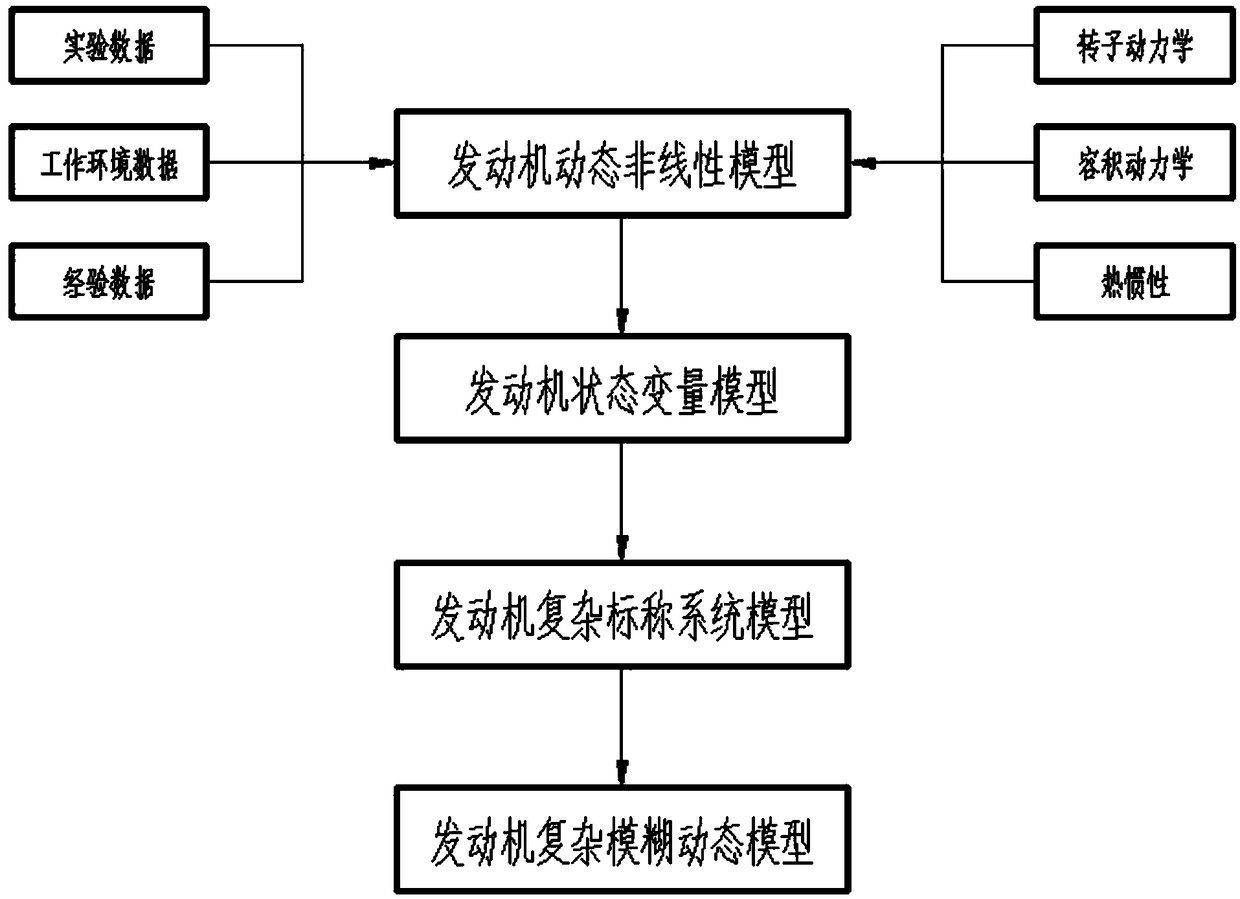

[0044] (1) Establish engine multi-dynamic component-level model

[0045] For a twin-shaft turbofan engine with afterburner, the cavity to be considered is selected from the combustion chamber, the high-low pressure turbine room, the connotation nozzle and the afterburner chamber, etc. The components that do not consider the cavity are the intake duct, fan, compressor, Outer bypass, high pressure turbine, low pressure turbine, mixing chamber and tailpipe.

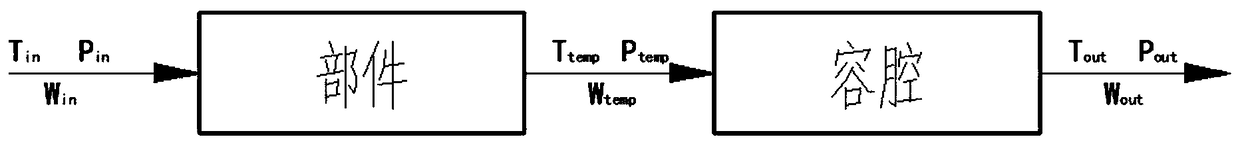

[0046] Establish a component-level model that considers the components of the cavity, consider the volume effect of the cavity (the accumulation effect of flow and energy) after the component-level model, establish a volume dynamics model for the corresponding cavity, and realize the correction of the temperature and pressure of the component. Thus, a volume dynamics model considering the cavity parts is established.

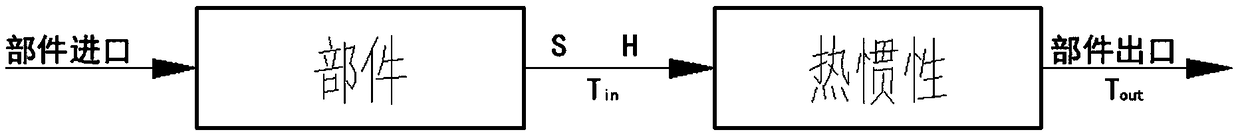

[0047] Select the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com