Preparation method of ultrafine tungsten trioxide material

A technology of tungsten trioxide and sodium tungstate, applied in the nano field, can solve the problems of dispersion and serious agglomeration of ultrafine tungsten trioxide, and achieve the effect of solving the problem of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

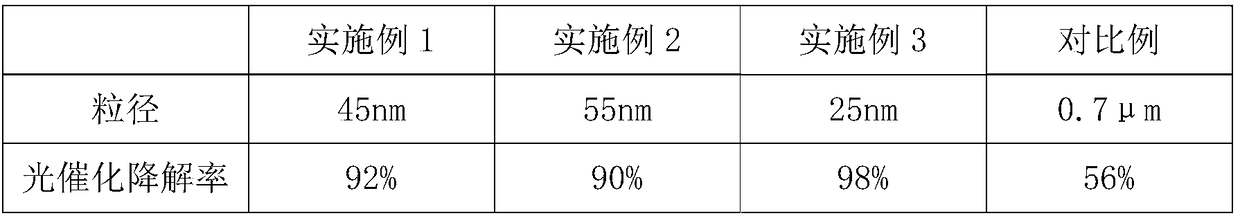

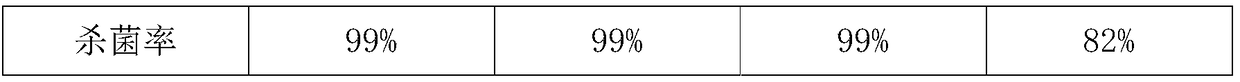

Examples

Embodiment 1

[0031] A method for preparing an ultrafine tungsten trioxide material, comprising the steps of:

[0032] Step 1: Add sodium tungstate to distilled water and stir ultrasonically until it is completely dispersed, then add methylcellulose and stir ultrasonically at low temperature until completely dissolved to obtain an aqueous solution of sodium tungstate;

[0033] Step 2, add concentrated hydrochloric acid to the sodium tungstate aqueous solution and mechanically stir until completely dispersed, then add absolute ethanol and stir evenly to obtain a mixed solution;

[0034] Step 3, adding the mixed solution into the reaction kettle to stand for heating for 1 hour, then ultrasonically dispersing at a constant temperature for 2 hours, and after filtering while hot, use anhydrous ethanol to clean the filtrate at a constant temperature ultrasonically for several times to obtain a gel;

[0035] Step 4, put the gel into anhydrous methanol and ultrasonically disperse it evenly, then ca...

Embodiment 2

[0046] A method for preparing an ultrafine tungsten trioxide material, comprising the steps of:

[0047] Step 1: Add sodium tungstate to distilled water and stir ultrasonically until it is completely dispersed, then add methylcellulose and stir ultrasonically at low temperature until completely dissolved to obtain an aqueous solution of sodium tungstate;

[0048] Step 2, add concentrated hydrochloric acid to the sodium tungstate aqueous solution and mechanically stir until completely dispersed, then add absolute ethanol and stir evenly to obtain a mixed solution;

[0049] Step 3, adding the mixed solution into the reaction kettle and standing for heating for 3 hours, then ultrasonically dispersing at a constant temperature for 4 hours, and after filtering while hot, use absolute ethanol to clean the filtrate at a constant temperature and ultrasonically for several times to obtain a gel;

[0050] Step 4, put the gel into anhydrous methanol and ultrasonically disperse it evenly,...

Embodiment 3

[0061] A method for preparing an ultrafine tungsten trioxide material, comprising the steps of:

[0062] Step 1: Add sodium tungstate to distilled water and stir ultrasonically until it is completely dispersed, then add methylcellulose and stir ultrasonically at low temperature until completely dissolved to obtain an aqueous solution of sodium tungstate;

[0063] Step 2, add concentrated hydrochloric acid to the sodium tungstate aqueous solution and mechanically stir until completely dispersed, then add absolute ethanol and stir evenly to obtain a mixed solution;

[0064] Step 3, adding the mixed solution into the reaction kettle to stand for heating for 2 hours, then ultrasonically dispersing at a constant temperature for 3 hours, and after filtering while hot, use absolute ethanol to clean the filtrate at a constant temperature and ultrasonically for several times to obtain a gel;

[0065] Step 4, put the gel in anhydrous methanol and ultrasonically disperse it evenly, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com