Microwell plate cleaning device for immunoassay experiment and use method

A technology for immunoassay and cleaning device, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of cross-contamination, affecting the experimental results, and leaving a lot of lotion, and achieves good use effect. , accurate position, good effect of injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

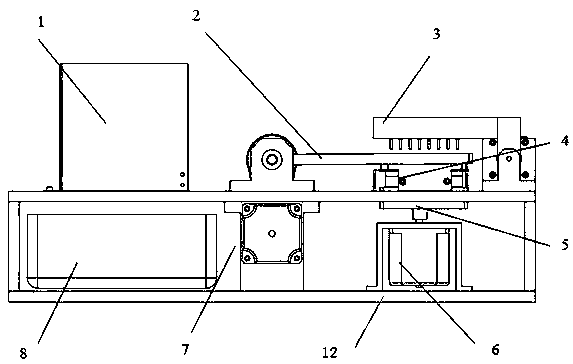

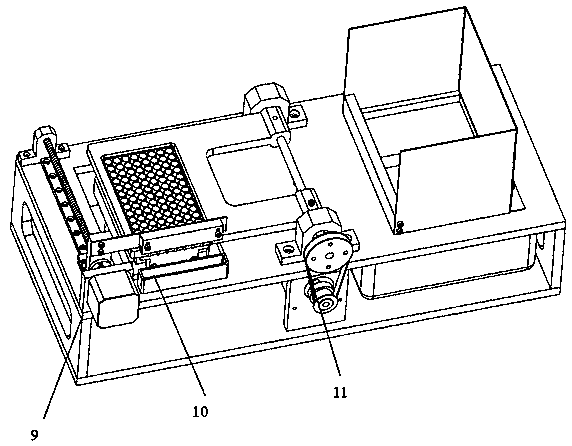

[0020] A microplate cleaning device used in immunoassay experiments, which consists of a frame 12, which is connected to a mixing motor 6 and a rocker motor 7 and fixed by screws, and the rocker motor 7 is connected to the rocker arm 2, the rocker arm 2 is connected to the rocker arm synchronization wheel 11, the mixing motor 6 is connected to the mixing tray 5 with an eccentric wheel, and the mixing tray 5 is connected to the magnet frame 4, so The top of the frame 12 is connected with a liquid injection head moving motor 9, and the liquid injection head moving motor 9 is connected with the liquid injection head 3.

Embodiment 2

[0022] A microplate cleaning device used in immunoassay experiments described in Example 1, wherein the frame 12 is connected to the waste liquid bin 8, the top of the frame 12 is connected to the protective cover 1, and the machine The top of the frame 12 is connected to the washing liquid tank 11, and the magnet frame 4 is connected to the magnet base.

Embodiment 3

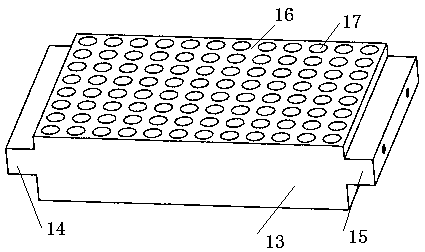

[0024] A microplate cleaning device used in an immunoassay experiment described in embodiment 2, the magnet base includes a base 13, and the base 13 is connected to the left ear plate 14 and the right ear plate 15, and the base 13 is inserted into the cylindrical magnet of the magnet holder 4, the base 13 is connected to the microporous plate 16, the base 13 and the microporous plate 16 are opened with a set of communicating micro-holes 17, the The micro sockets 17 are parallel to each other laterally and parallel to each other vertically, and the sockets 17 correspond to the liquid injection head 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com