A new low-temperature plasma preparation process of superhydrophobic silica

A technology of low-temperature plasma and low-temperature plasma, which is applied in the treatment of dyed low-molecular organic compounds, fibrous fillers, etc., can solve the problems of difficult practical application and high equipment requirements, and achieve product quality assurance, industrial cost reduction, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

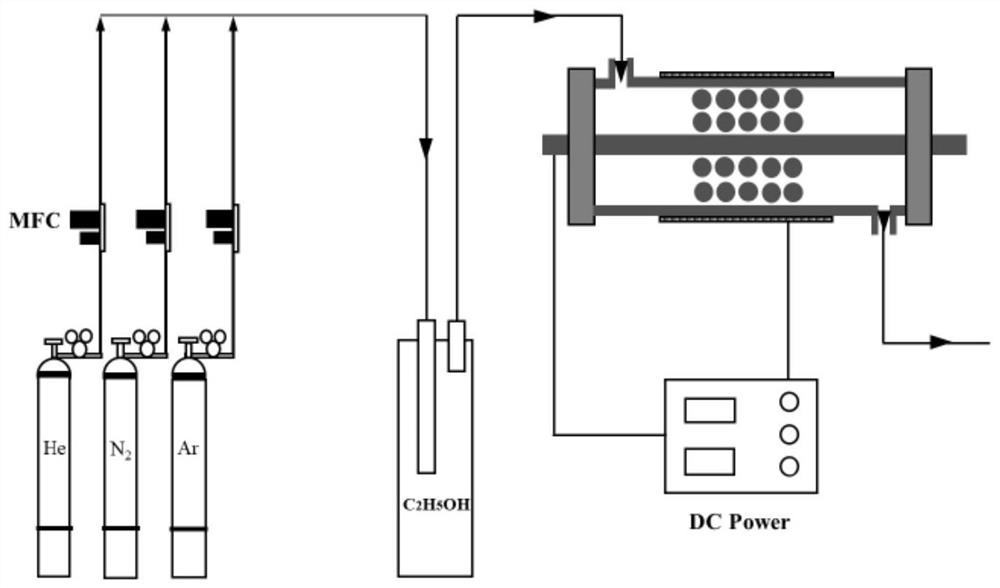

Image

Examples

Embodiment 1

[0025] Put 20g of white carbon black into the low-temperature plasma device; vaporize the modifier at 100°C and mix it with He with a flow rate of 120ml / min; pass the mixed gas into the low-temperature plasma device, the plasma discharge mode For corona discharge, the plasma discharge power is 10W, start the device, react for 60min, and the temperature is 50°C. Repeat the above steps three times. The effects of different modifiers on the properties of hydrophobic silica are shown in Table 1.

[0026] Table 1 Effect of different modifiers on the properties of hydrophobic silica

[0027] Modifier type Static water contact angle (°) ethanol 135.7 Ethylene glycol 138.7 Butanol 142.7 Glycerol 143.7 Ethyl chloride 139.0 Dichloroethane 140.9 Monochloropropane 142.6 Ethylene glycol + monochloropropane 144.7 Ethanol + Dichloroethane 141.2 Glycerol + monochloropropane 143.8

Embodiment 2

[0029] Put 20g of white carbon black into the low-temperature plasma device; vaporize glycerol at 100°C and mix it with a carrier gas with a flow rate of 120ml / min; pass the mixed gas into the low-temperature plasma device, and the plasma discharge The method is corona discharge, the plasma discharge power is 10W, the device is started, the reaction is 60min, and the temperature is 50°C. Repeat the above steps three times. The effects of different carrier gases on the properties of hydrophobic silica are shown in Table 2.

[0030] Table 2 Effect of different carrier gases on the properties of hydrophobic silica

[0031] Type of carrier gas Static water contact angle (°) Ar 142.8 he 143.7 N2 142.1

Embodiment 3

[0033] Put 20g of white carbon black into the low-temperature plasma device; vaporize glycerol at a certain temperature and mix it with He with a flow rate of 120ml / min; pass the mixed gas into the low-temperature plasma device, and the plasma discharge method For corona discharge, the plasma discharge power is 10W, start the device, react for 60min, and the temperature is 50°C. Repeat the above steps three times. The effects of different vaporization temperatures on the properties of hydrophobic silica are shown in Table 3.

[0034] Table 3 Effect of different vaporization temperatures on the properties of hydrophobic silica

[0035] Vaporization temperature (℃) Static water contact angle (°) 50 142.9 100 143.7 150 143.9 200 144.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com