Novel straddle type monorail double-line combined track beam structure

A straddle-type monorail and track beam technology, which is applied in the field of rail transit, can solve the problems of affecting driving safety, easy cracking of steel boxes, and many structural welds, so as to achieve good overall performance, ensure welding quality, and small web damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

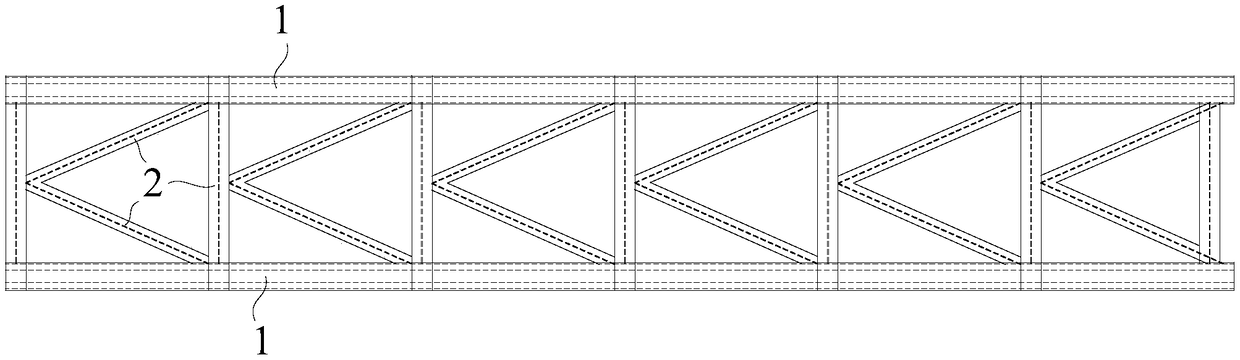

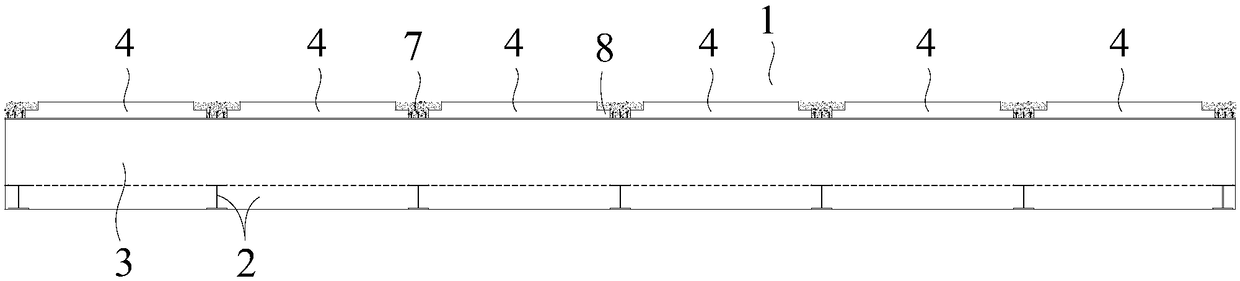

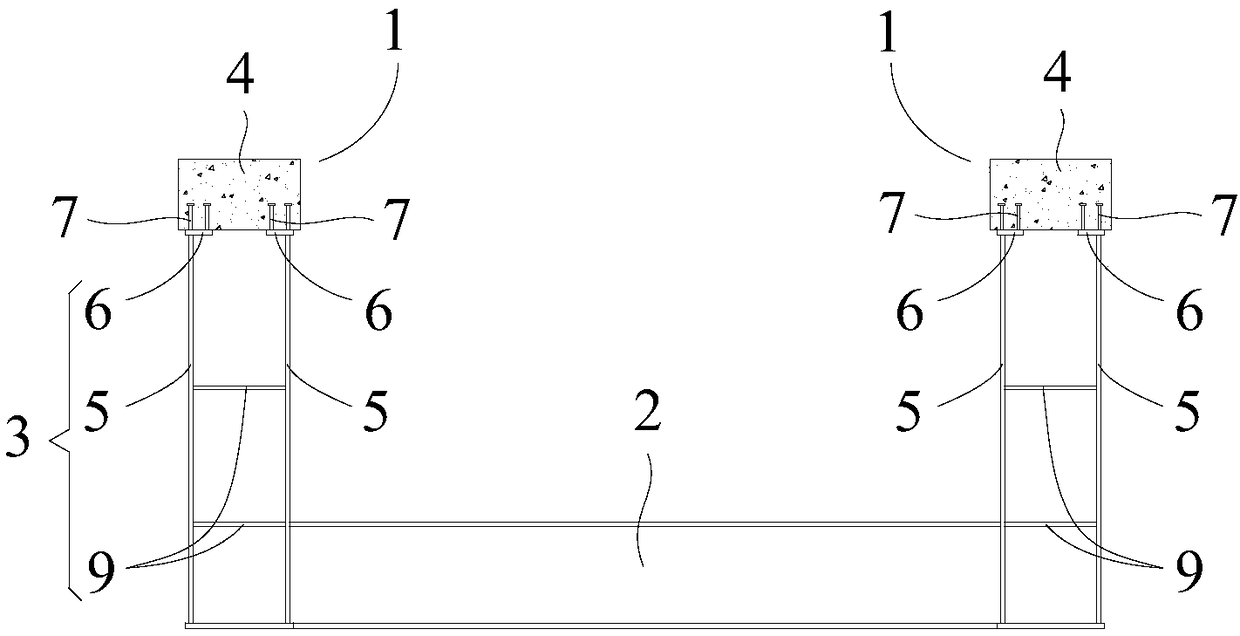

[0034] like Figure 1-4 As shown, a novel straddle-type single-track double-line composite track beam structure according to the present invention includes two opposite track beams 1 , each track beam 1 includes a steel box 3 and a prefabricated OPC board 4 .

[0035]The steel box 3 includes two oppositely arranged webs 5, the top of each web 5 is connected to the top plate 6 to form a T-shaped plate structure, there is a gap between the two top plates 6, and each of the top plates 6 is provided with A plurality of shear stud groups 7, a prefabricated OPC board 4 is arranged between two adjacent shear stud groups 7, and each of the prefabricated OPC boards 4 is provided with protrusions 8 at the bottom of both ends, pouring In the area between the ends of two adjacent prefabricated OPC panels 4, the adjacent two prefabricated OPC panels 4 and the corresponding shear stud groups 7 are integrated, so that the prefabricated OPC panels 4 The steel box 3 is connected, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com