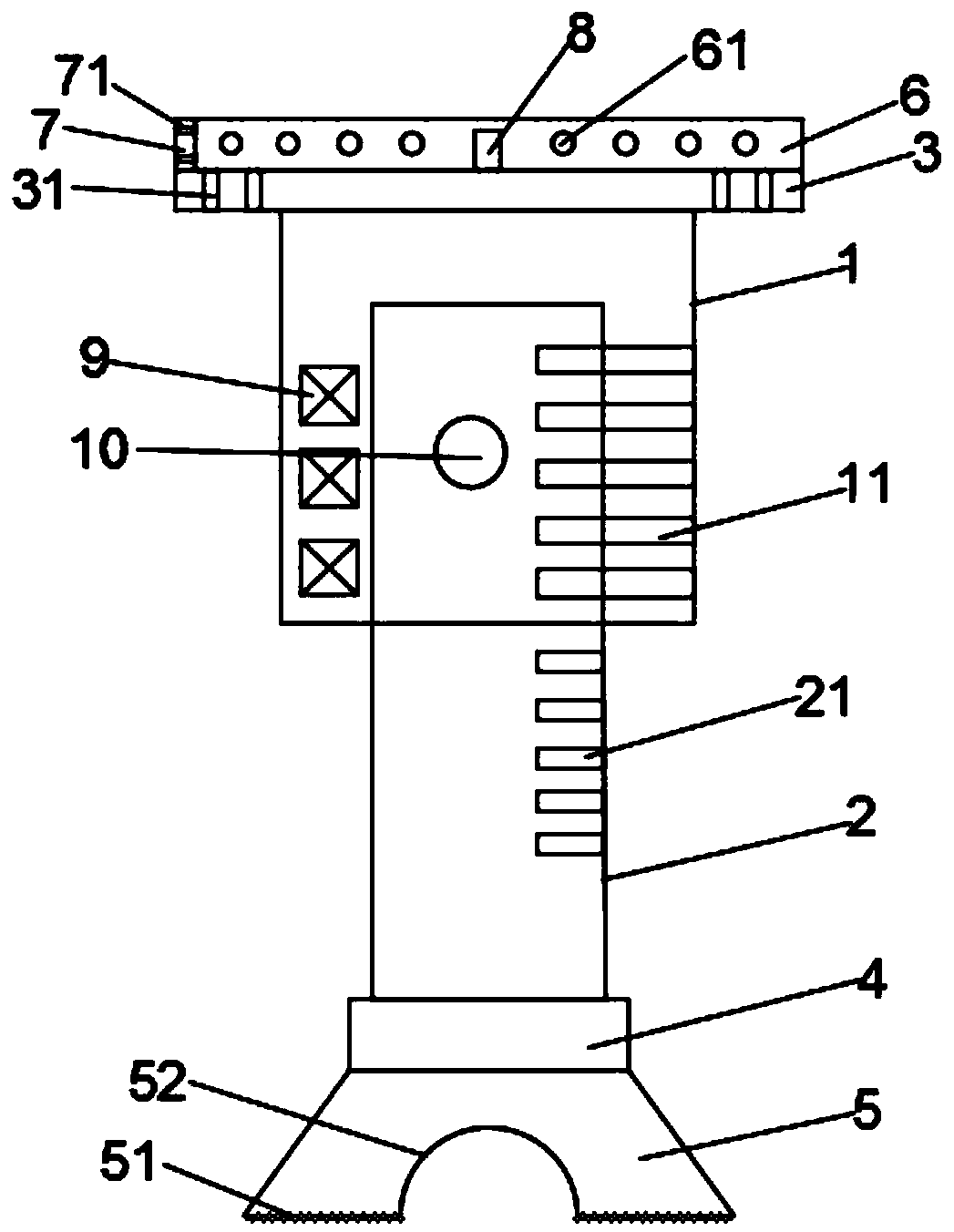

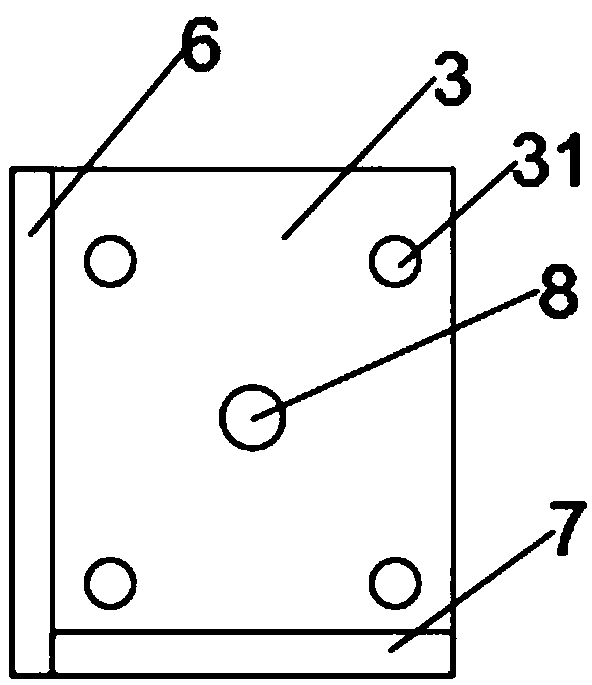

Height-adjustable cabinet leg with night vision function

An adjustable and functional technology, applied in the field of hardware and furniture, can solve the problems of non-adjustable, complex and single function, and achieve the effect of simple and reasonable structure, improved installation speed and strong function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the antirust and antibacterial coating comprises the following steps: mixing nano-zinc powder, modified nano-zinc oxide, ceramic powder, mica powder, halloysite micropowder and high-strength carbon fiber in a formula quantity, adding formula quantity 2 / 3 of deionized water dispersed for 20min to prepare the slurry; adding water-based epoxy resin, anionic acrylic resin emulsion, acrylic acid-maleic anhydride copolymer (PAA-PMA), sodium gluconate, 1-hydroxyethylene -1,1-diphosphonic acid (HEDP) and tung oil, then stirred and reacted at 1000r / min for 1h; cooled to room temperature, then added the remaining 1 / 3 of deionized water and continued to stir at 600r / min for 30min.

Embodiment 2

[0029] The preparation method of the antirust and antibacterial coating comprises the following steps: mixing nano-zinc powder, modified nano-zinc oxide, ceramic powder, mica powder, halloysite micropowder and high-strength carbon fiber in a formula quantity, adding formula quantity 2 / 3 deionized water dispersed for 30min to prepare slurry; add water-based epoxy resin, anionic acrylic resin emulsion, acrylic acid-maleic anhydride copolymer (PAA-PMA), sodium gluconate, 1-hydroxyethylene -1,1-Diphosphonic acid (HEDP) and tung oil were then stirred and reacted at 1200r / min for 2h; after cooling down to room temperature, the remaining 1 / 3 of deionized water was added and continued to stir at 800r / min for 50min.

Embodiment 3

[0031]The preparation method of the antirust and antibacterial coating comprises the following steps: mixing nano-zinc powder, modified nano-zinc oxide, ceramic powder, mica powder, halloysite micropowder and high-strength carbon fiber in a formula quantity, adding formula quantity 2 / 3 deionized water dispersed for 25min to prepare a slurry; add water-based epoxy resin, anionic acrylic resin emulsion, acrylic acid-maleic anhydride copolymer (PAA-PMA), sodium gluconate, 1-hydroxyethylene -1,1-diphosphonic acid (HEDP) and tung oil, then stirred at 1100r / min for 1.5h; cooled to room temperature, then added the remaining 1 / 3 of deionized water and continued to stir at 700r / min for 40min.

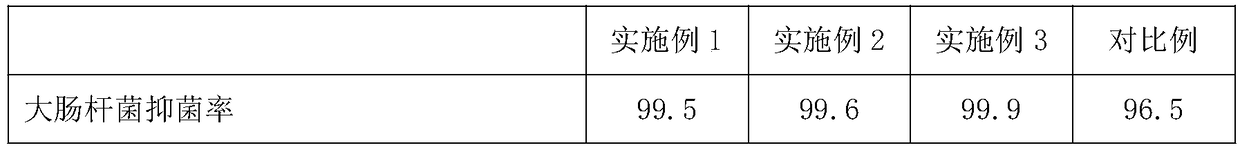

[0032] Table 1 is the composition list (unit: part) of the antirust antibacterial coating of the embodiment of the present invention; Table 2 is the antibacterial rate (unit: %) of the antirust antibacterial coating of the embodiment of the present invention;

[0033] Table 1 is the composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com