Boiler sand blasting and spraying construction method based on boiler maintenance platform

A technology of maintenance platform and construction method, applied in the directions of injection device, manufacturing tool, metal processing equipment, etc., can solve the problems of hidden danger of personal safety, waste of time and energy, secondary maintenance injury of slope water wall, etc., to avoid falling objects from high altitude. safety hazards, convenient installation and disassembly, and the effect of avoiding high-altitude falls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

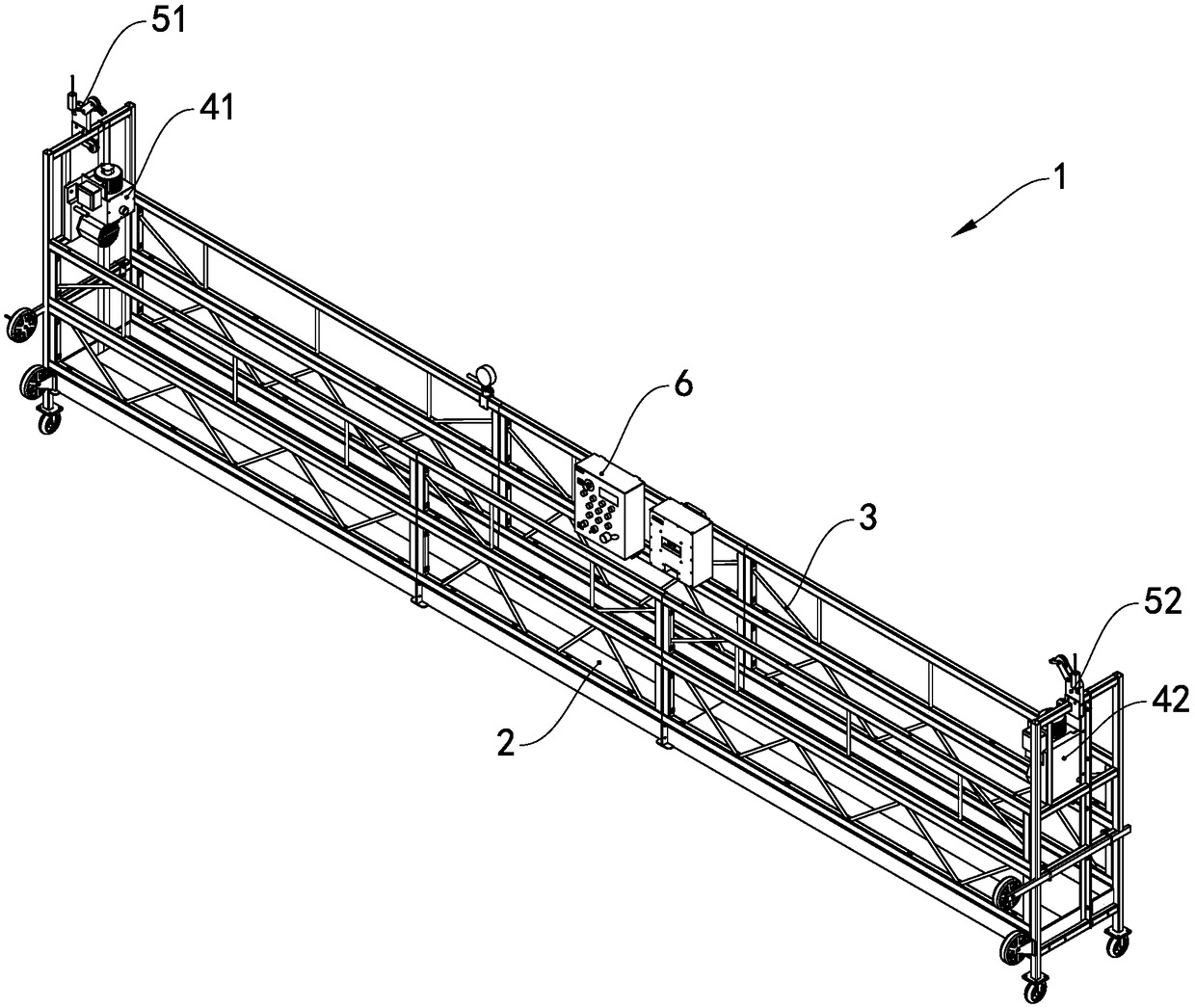

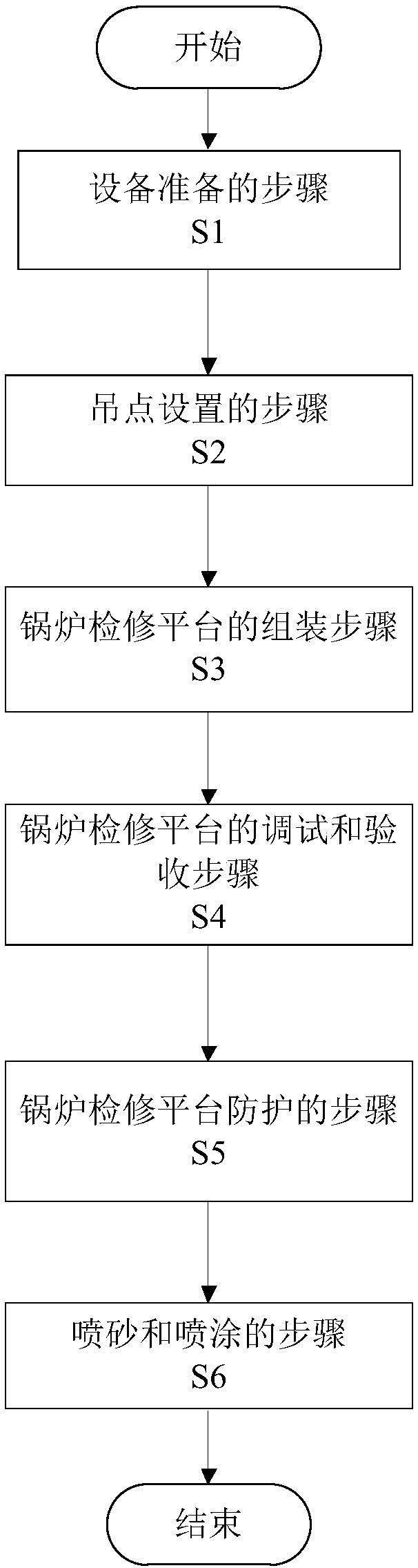

[0035] see figure 1 , a boiler sandblasting and spraying construction method of the boiler maintenance platform 1 of the present embodiment is to use the boiler maintenance platform 1 to transport workers to blast and spray the boiler. The purpose of sand blasting is to remove the oxide layer on the surface of the boiler, and the purpose of spraying is to protect the surface of the boiler by spraying and prolong the service life of the boiler. The sandblasting and spraying construction method of the boiler in this embodiment is suitable for sandblasting and spraying of the hedging boiler, the four-corner tangential boiler, the double tangential boiler, the tower boiler, the glazed chamber boiler and the W boiler.

[0036] Boiler maintenance platform 1 is set on the side wall of the boiler so that it can move vertically up and down through steel wire ropes. Boiler maintenance platform 1 includes lifting platform 2, guardrail 3, central control box 6, magnetic absorber (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com