ELectric vehicLe instrumentation system and scheduLing method thereof

An instrument system and electric vehicle technology, applied in the field of control, can solve problems such as the inability to change the execution sequence, large fluctuations in waiting time, and difficulty in ensuring real-time performance, and achieve the effects of convenient maintenance and transplantation, low scheduling overhead, and high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

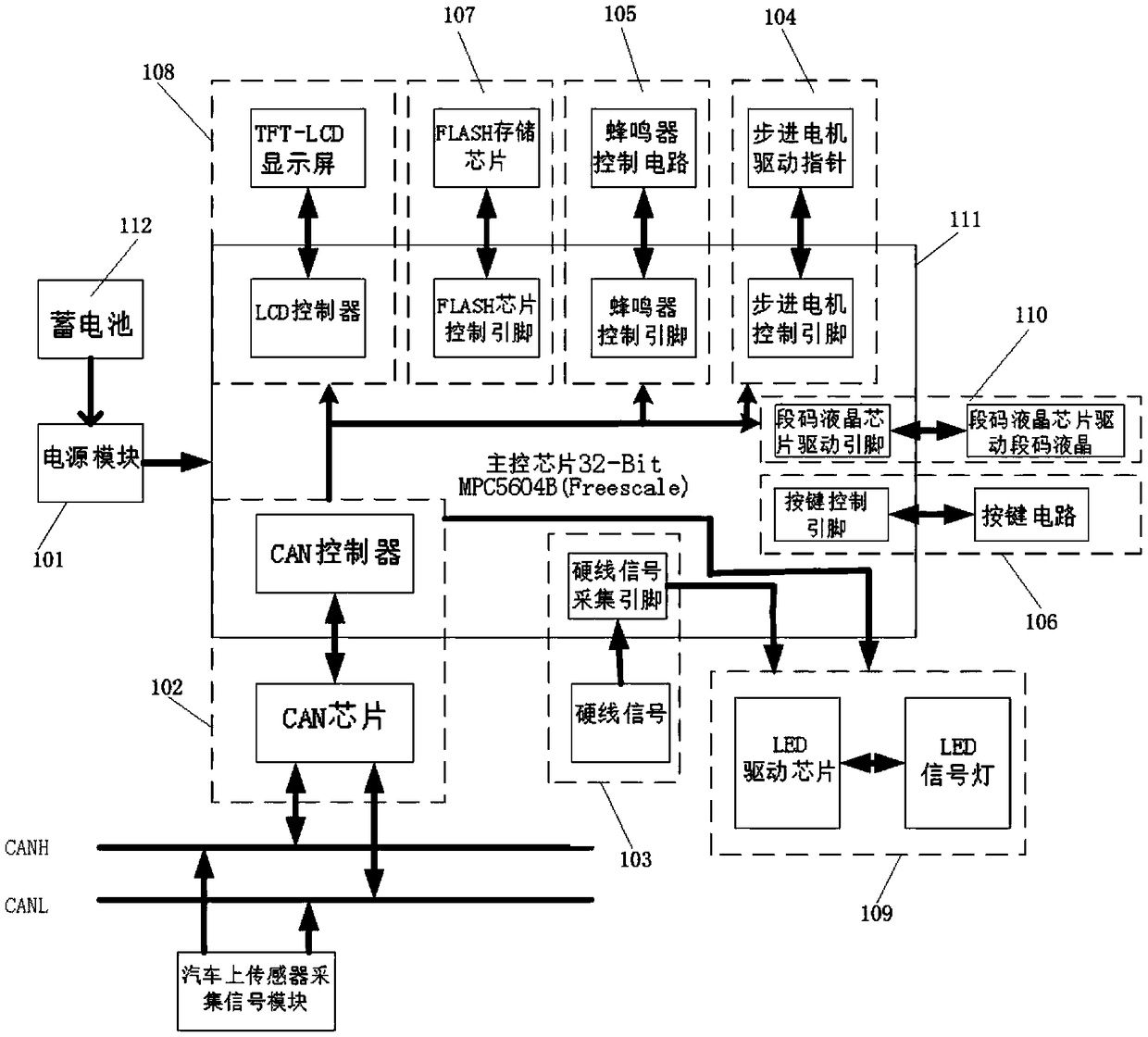

[0025] figure 1 It is a block diagram of the overall structure of the electric vehicle instrument system. The electric vehicle instrument system includes:

[0026] The power module 101 is used to convert the voltage provided by the storage battery 112 into the working voltage required by each component. The storage battery 112 provides 12V working voltage, and the normal working voltage of the device on the present invention is 5V, 3.3V, 1.8V and 1.1V respectively, such as the LED indicator module and the segment code liquid crystal drive chip etc. need 5V working voltage, emulator interface circuit etc. A 3.3V operating voltage is required, while 1.8V and 1.1V operating voltages are used on memory chips. The voltage in the present invention is further divided into two types: cut-off and non-cut-off, in order to reduce the static power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com