eps of a large vehicle

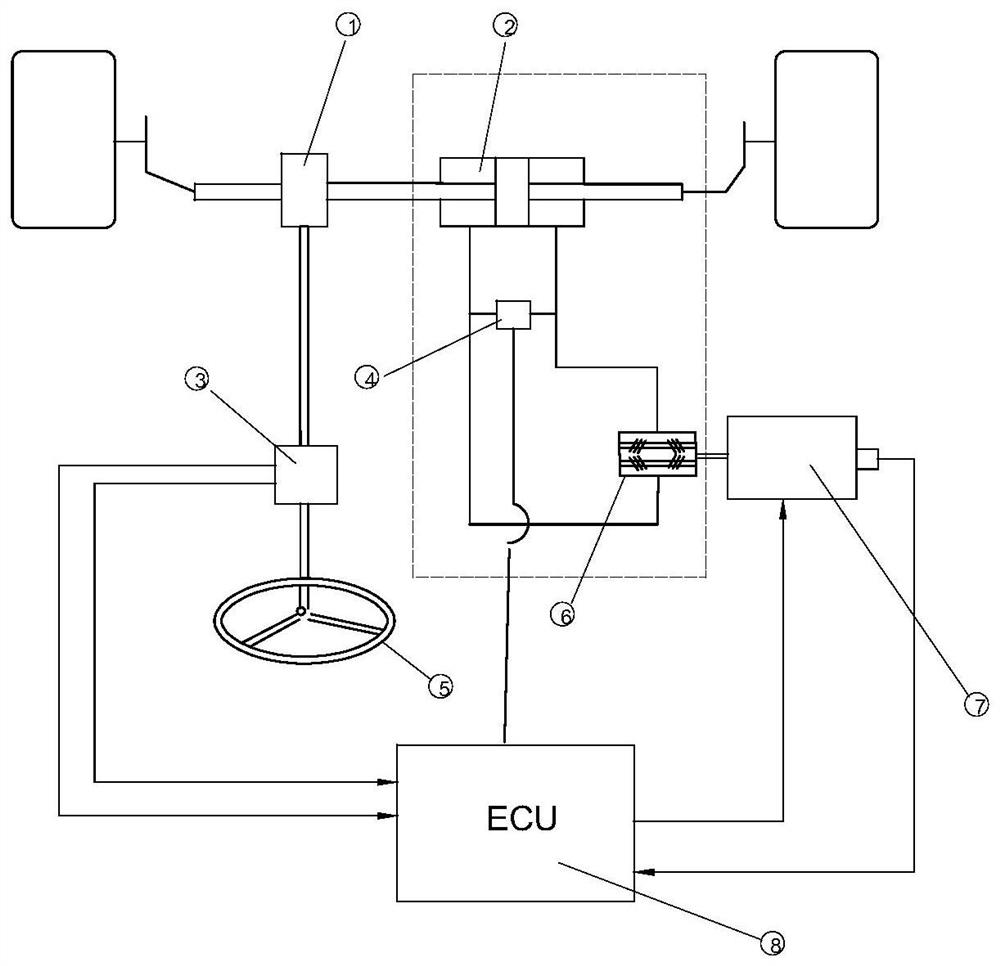

A vehicle, large-scale technology, applied in EPS. In the field of large-scale commercial vehicles, it can solve the problems of large-scale commercial vehicles that cannot be boosted by high power, cannot adjust the size of the boost value, and increase system energy loss, and achieve the effects of eliminating reverse drive requirements, reducing inertia, and reducing manufacturing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

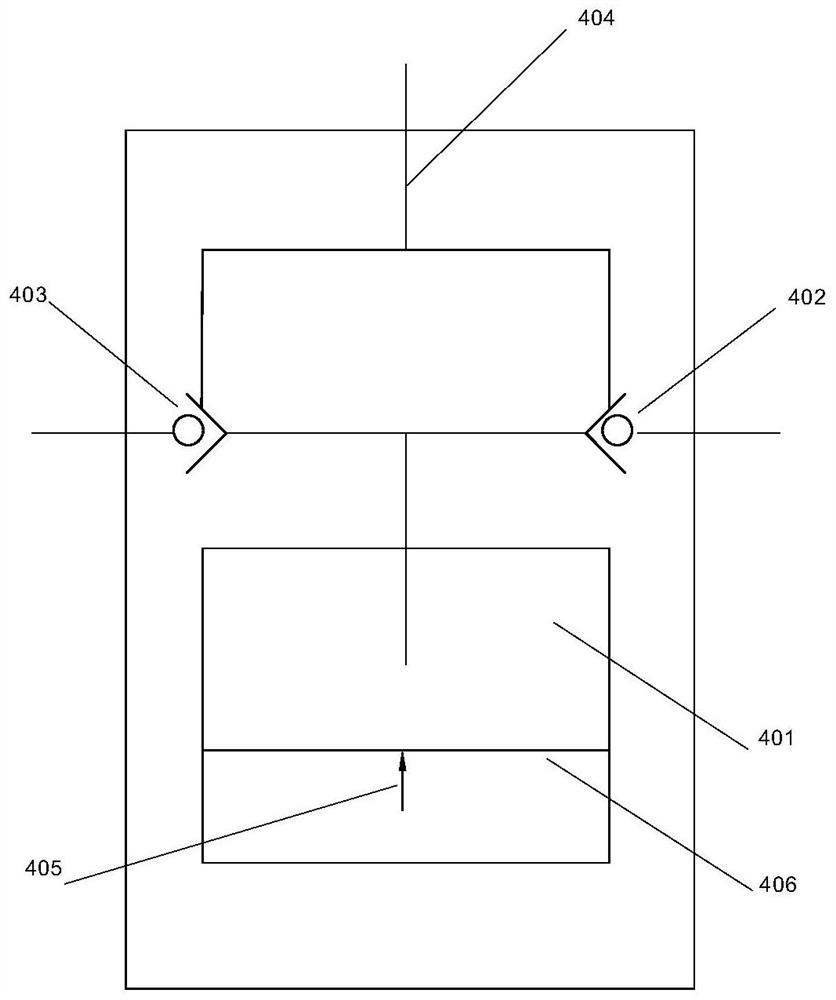

[0019] Embodiment 1: The controller 8 can control the current of the servo motor 7 according to the status signals such as the vehicle speed and the magnitude of the torque, and the servo motor 7 will drive the hydraulic pump 6 according to the magnitude of the current, and the output hydraulic pressure of the hydraulic pump 6 is the same as that of the servo motor. 7 is proportional to the current. The hydraulic pressure output by the hydraulic pump 6 directly drives the hydraulic actuators of the steering system, such as hydraulic cylinders or recirculating ball steering machines.

[0020] When the signal is reversed, the servo motor 7 reverses, and the hydraulic pump 6 has a symmetrical forward and reverse characteristic, exchanging the input and output flow; the reduction of the circuit stiffness of the hydraulic system will have an adverse effect on the execution of the system. By improving The rigidity of the pipeline can be reduced, and the pressure compensator in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com