A continuously adjustable electrode spacing desalination technology and reaction module for electroadsorption-regeneration

A technology of electrode spacing and electro-adsorption, which is applied in separation methods, special treatment targets, and separation of dispersed particles, can solve problems such as reaching the adsorption platform quickly, low electrode regeneration rate, and increased economic costs, so as to improve electrode regeneration rate, Effect of reducing secondary adsorption and high desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, desalination device

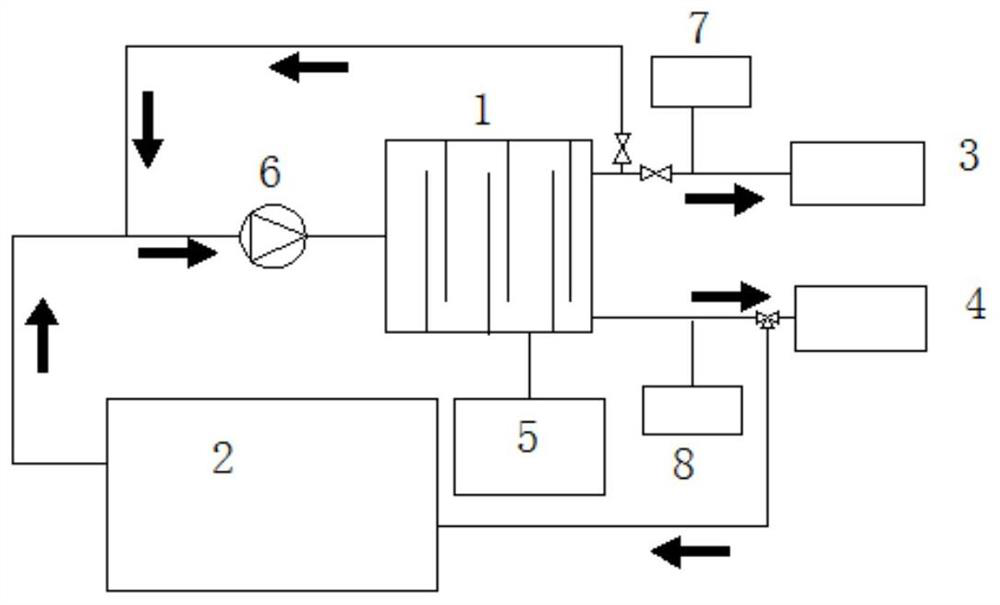

[0022] The desalination reactor includes an electric adsorption desalination device box 1, a raw water tank 2, a clean water tank 3, a final concentrated water tank 4, a power supply 5, a water pump 6, and a conductivity meter 7, 8:

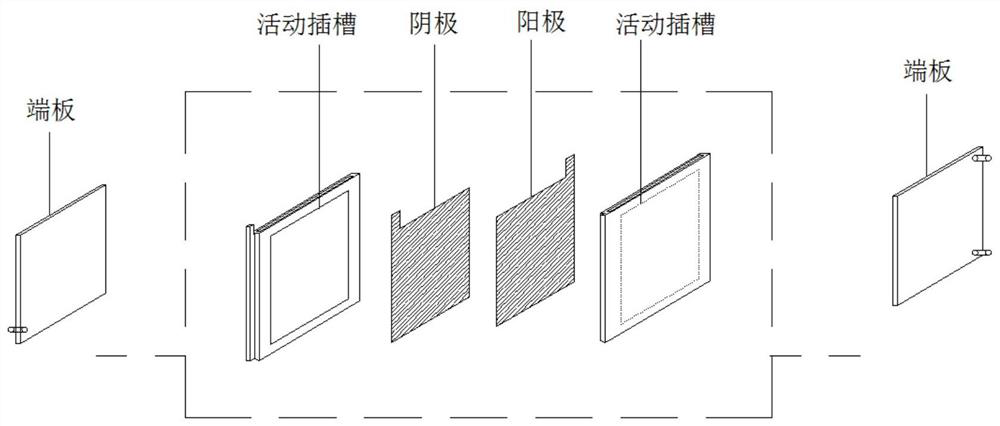

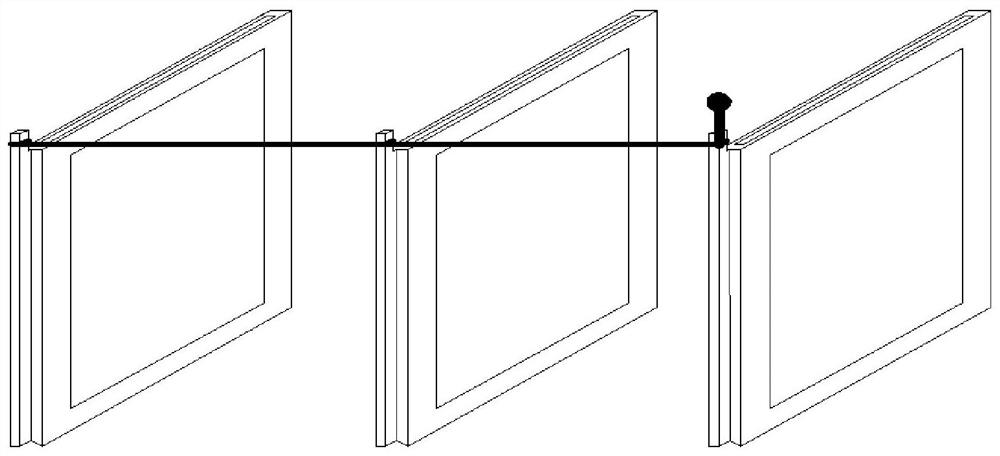

[0023] Wherein, the power supply 5 is connected with the electro-adsorption desalination device box 1 through wires to form a loop. The power supply 5 is an adjustable DC power supply within the voltage range of 0-1.5V. The water pump 6 is a peristaltic pump with an adjustable water inlet flow rate of 0-40mL / min. The conductivity meters 7 and 8 are the same conductivity meters with a measurement range of 0 to 5000 μS / cm. The box body of the electro-adsorption desalination device includes 6 pairs of electrode plates. The electrode plates are flat electrodes with positive and negative electrodes placed opposite each other and form a baffle channel; the materials constituting the electrode plates include ...

Embodiment 2

[0024] Embodiment 2, electric adsorption-regeneration

[0025] Connect the electro-adsorption desalination device box 1 in Example 1 to the power supply 5 through wires and turn on the power supply during the electrification and adsorption stage. The relative conductivity is 3200±100 μS / cm, Cl - The external drainage of landfill leachate with a concentration of 560±20 μS / cm is desalinated, and the adsorption desalination conditions are shown in Table 1.

[0026] Table 1 Electrosorption-regeneration treatment conditions

[0027]

[0028] After completion of desalination, the desalination rate was 42.6%, Cl - The removal rate was 66.7%, Ca 2+ The removal rate is 80.2%, Mg 2+ The removal rate is 73.3%, the desalination rate is 90mg / (L h), and the current density is stable at 2.5-3.0mA / cm during the desalination process 2 . After completion of electrode regeneration, the electrode regeneration rate was 97.3%, and the water production rate was 91.7% after 4 operating cycles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com