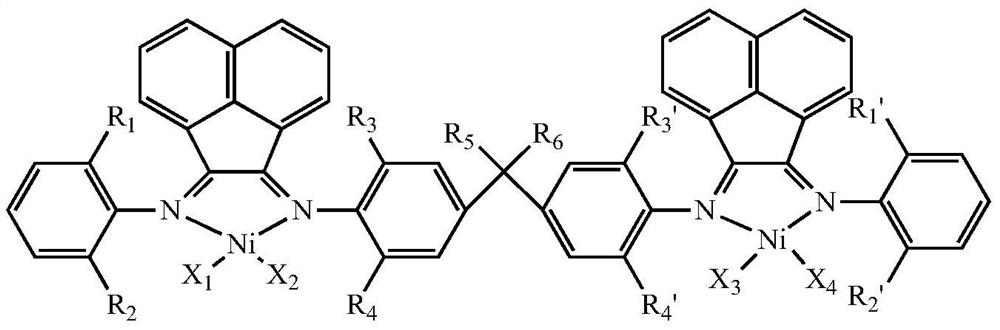

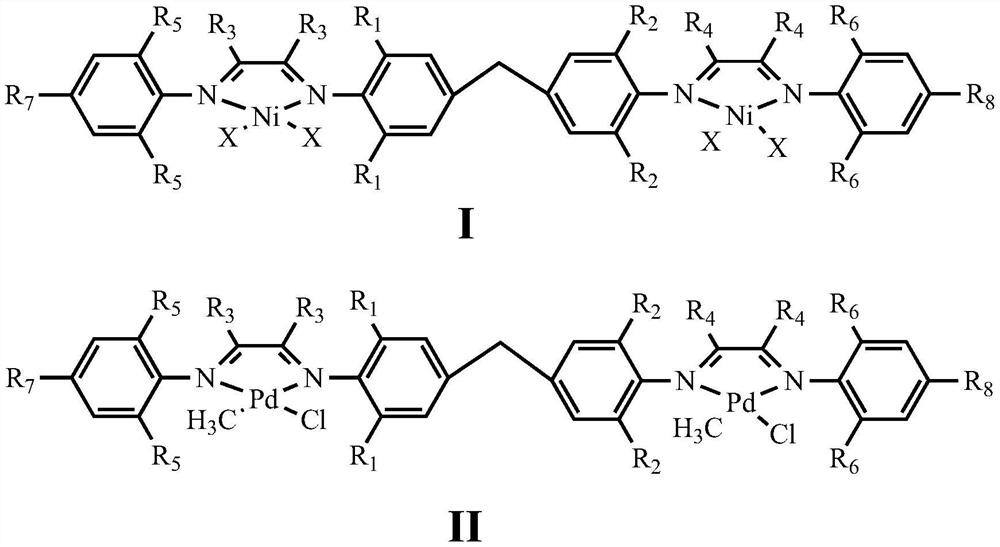

A kind of dinuclear (α-diimide) nickel/palladium olefin catalyst, preparation and application

A technology of olefin catalyst and diimine, which is applied in the field of dual-nuclear nickel/palladium olefin catalyst and its preparation, can solve the problems of single catalyst and single molecular structure, and achieve the effect of diversification of molecular structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

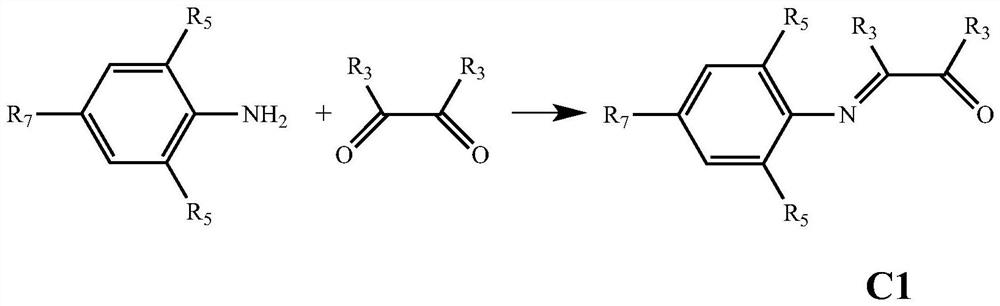

[0045] Synthesis of Ligand L1

[0046] The chemical structural formula of ligand L1 is as follows:

[0047]

[0048] Under nitrogen atmosphere and 85°C, add 2mmol of acenaphthoquinone into a three-necked flask containing 80mL of acetonitrile, add 15mL of acetic acid after half an hour, stir and dissolve for two hours, then add 2mmol of 4-nitro-2,6-di Cumyl aniline (dissolved in 20 mL of acetonitrile in advance) was added dropwise into the three-necked flask. After 24 hours, stop the reaction, let it stand, cool naturally, and the product precipitates out. The precipitate was washed with 5×50 mL of n-heptane, and then dried under vacuum at 70° C. for 48 hours. The product C1-10.515g was obtained with a yield of 75%.

[0049] Under nitrogen atmosphere and 85°C, add 2mmol of acenaphthylquinone into a three-necked flask containing 80mL of acetonitrile, half an hour later, add 15mL of acetic acid, stir and dissolve for two hours, then add 2mmol of 4-(N,N-dimethyl ) Amino-2,6...

Embodiment 2

[0054] Synthesis of Ligand L2

[0055] The chemical structural formula of ligand L2 is as follows:

[0056]

[0057] Under nitrogen atmosphere and 85°C, add 2mmol 2,3-butanedione into a three-necked flask containing 80mL acetonitrile, add 15mL acetic acid after half an hour, stir and dissolve for two hours, then add 2mmol 4-trifluoroform Base-2,6-diisopropylaniline (dissolved in 20 mL of acetonitrile in advance) was added dropwise into the three-necked flask. After 24 hours, stop the reaction, let it stand, cool naturally, and the product precipitates out. The precipitate was washed with 5×50 mL of n-heptane, and then dried under vacuum at 70° C. for 48 hours. 0.353 g of the product C1-2 was obtained with a yield of 72%.

[0058] Under nitrogen atmosphere and 85°C, 2mmol 2,3-butanedione was added to a three-necked flask filled with 80mL acetonitrile. Half an hour later, 15mL acetic acid was added, stirred and dissolved for two hours, and 2mmol 4-(N, N-dimethyl)amino-2,6...

Embodiment 3

[0063] Synthesis of Ligand L3

[0064] The chemical structural formula of ligand L3 is as follows:

[0065]

[0066] Under nitrogen atmosphere and 85°C, add 2mmol glyoxal into a three-neck flask containing 80mL acetonitrile, add 15mL acetic acid after half an hour, stir and dissolve for two hours, then add 2mmol 4-bromo-2,6-di Cumyl aniline (dissolved in 20 mL of acetonitrile in advance) was added dropwise into the three-necked flask. After 24 hours, stop the reaction, let it stand, cool naturally, and the product precipitates out. The precipitate was washed with 5×50 mL of n-heptane, and then dried under vacuum at 70° C. for 48 hours. The product C1-30.326g was obtained with a yield of 75%.

[0067] Under nitrogen atmosphere and 85°C, add 2mmol glyoxal into a three-necked flask filled with 80mL acetonitrile. After half an hour, add 15mL acetic acid, stir and dissolve for two hours, then add 2mmol 4-(N,N-dimethyl Base) amino-2,6-diisopropylaniline (dissolved in 20 mL of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com