Photoinitiator composition, photocurable composition and photocurable product

A technology of photoinitiator and composition, applied in the field of photocuring, can solve the problem of low sensitization effect of combined sensitizer, and achieve the effect of improving sensitization, strong effect and sensitization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

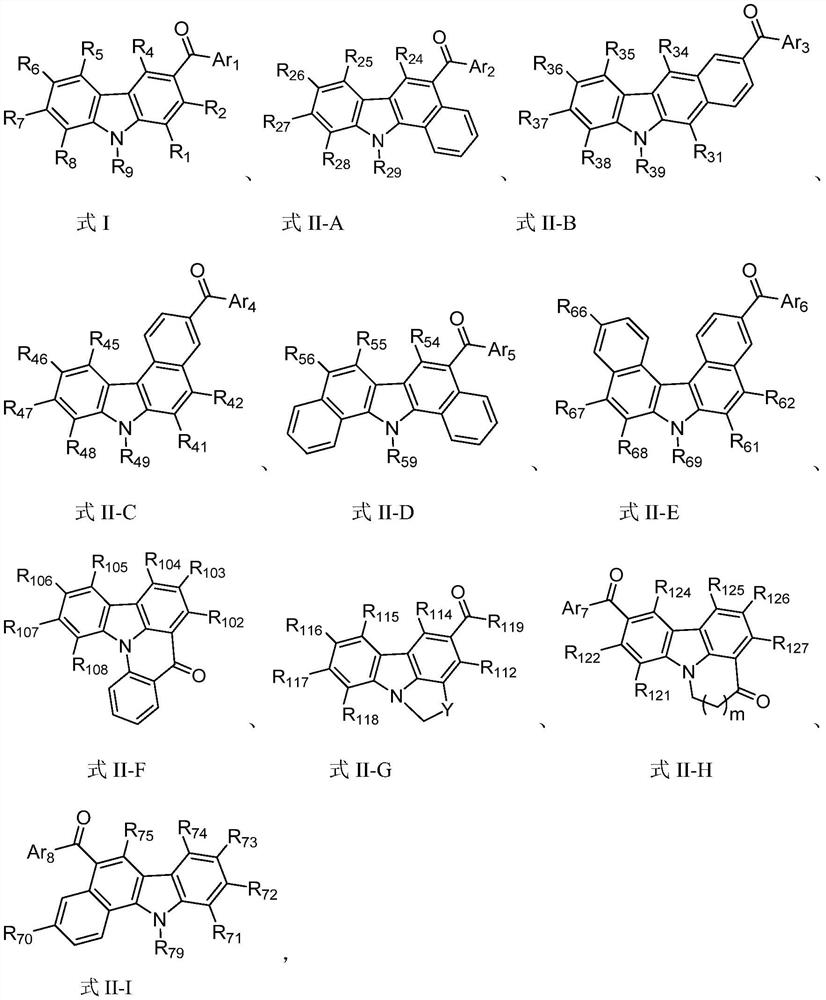

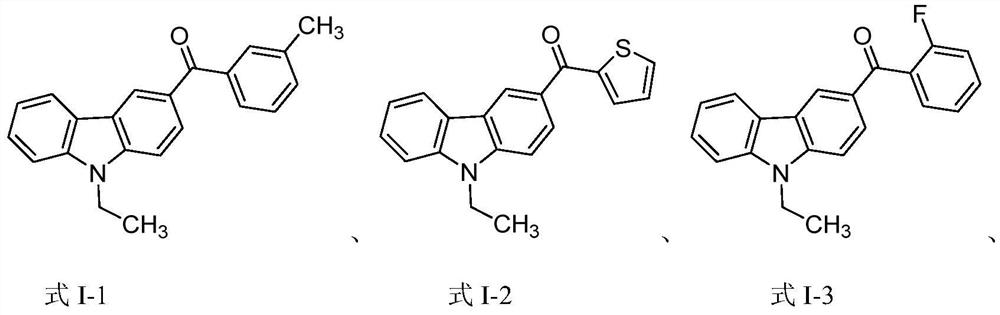

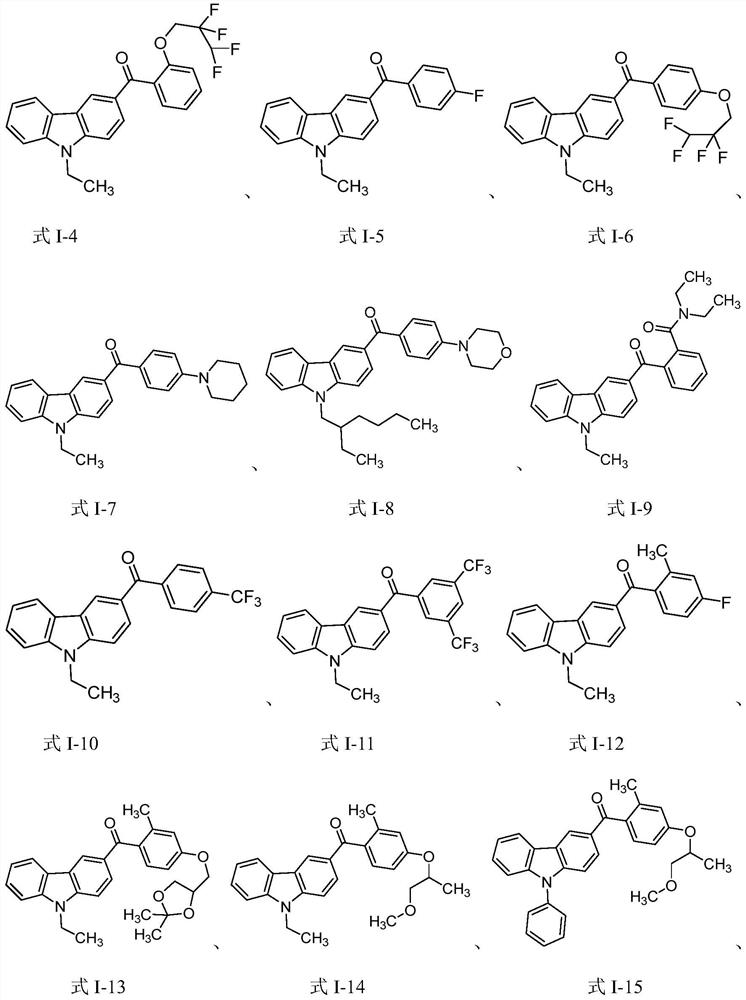

Method used

Image

Examples

preparation Embodiment 1

[0054] Dissolve 19.5g of N-ethylcarbazole in 250mL of dichloroethane, then add 34g of aluminum trichloride, keep it at 0~-5°C, add 40g of p-fluorobenzoyl chloride dropwise to the solution, and then keep the reaction solution React at 0-5°C for 15 hours. The reaction solution was added in batches to 100 mL of 10% HCl solution at 0° C., and stirred for 30 min after the addition was complete. After standing still for 30 minutes, the liquids were separated, and the dichloroethane phase was washed with 50 mL of 2% sodium hydroxide solution for 30 min, and the dichloroethane phase was separated. The dichloroethane solution was distilled under reduced pressure and the dichloroethane was recovered, and 80 mL of ethyl acetate was added to the residue to crystallize to obtain 30.5 g of 9-ethyl-3,6-bis(4-fluorobenzoyl)carbazole product, The white powder content is 98.5%, and the yield is 69.5%.

[0055] Dissolve 30g of 9-ethyl-3,6-bis(4-fluorobenzoyl)carbazole, 25g of 2,2,3,3-tetrafluo...

preparation Embodiment 2

[0057] Add 2.0g of 11-(2-ethylhexyl)-11H-benzo[a]carbazole into a 50mL single-necked bottle, add 20mL of dichloroethane to dissolve, add 0.2g of zinc chloride, 2.3g of o-fluorobenzoyl chloride , stirred at 80°C for 10 hours. After cooling down, the reaction solution was washed twice with 20 mL of water, and the dichloroethane solution was concentrated to dryness under reduced pressure to obtain 11-(2-ethylhexyl)-5,8 bis(4-fluorobenzoyl)-11H-benzene And [a] carbazole brown viscous.

[0058]Dissolve 4.0g of 11-(2-ethylhexyl)-5,8bis(4-fluorobenzoyl)-11H-benzo[a]carbazole in 20mL of pyridine in a 50mL one-necked bottle, then add tetrafluoropropanol 2.2 g and 1.2 g sodium hydroxide, heated to 80°C and stirred for 5 hours. The reaction solution was added dropwise to 100 mL of water, then stirred with 100 mL of dichloroethane for 1 h, and then left to separate layers. The separated dichloroethane solution was concentrated to dryness under reduced pressure to obtain 4.7 g of a brow...

preparation Embodiment 3

[0065] Take 6g of Omnicat 270 and 13.2g of the compound shown in formula I-30 and put them in a mortar for grinding and mixing to obtain a light yellow powder, which is a sample with a molar ratio of sensitizer to cationic photoinitiator active group of 2.85.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com