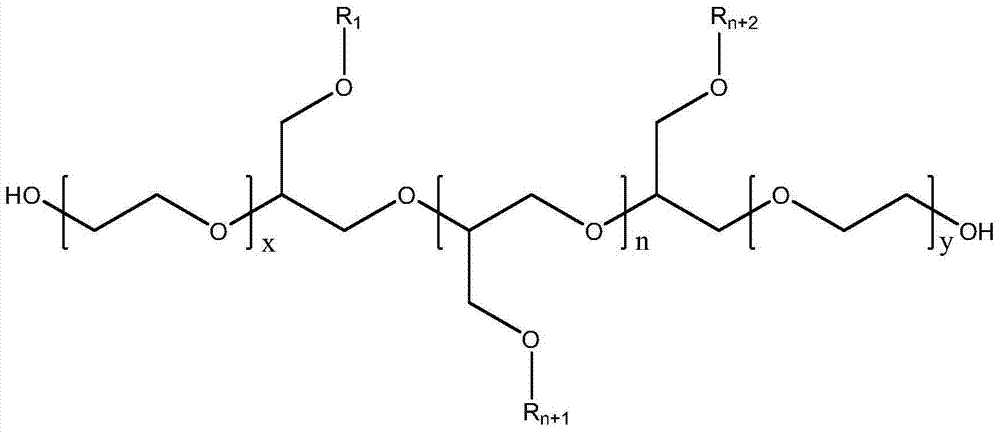

A kind of oligoglycerol ester/ether derivative and its synthesis method

A technology of oligoglycerol ester and synthesis method, which is applied in the field of oligoglycerol ester/ether and its synthesis, oligomer type nonionic surfactant, can solve problems such as application field limitations, and achieve wide application and low CMC concentration , the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Therefore, the preparation method of the derivative of oligoglycerol ester / ether of the present invention comprises the following steps:

[0063] 1) Put the monoglyceride / ether containing tertiary carbonyl or alkyl group into the reaction kettle as the base material, start stirring, put in the catalyst, replace the air in the reaction kettle with nitrogen, and raise the temperature to 110-180°C;

[0064] 2) Add the glycidyl ester / ether containing tertiary carbonyl or alkyl group dropwise into the reaction kettle, and the dropwise addition is completed within 4 to 12 hours;

[0065] 3) Steam the unreacted glycidyl ester / ether and refine to obtain oligoglycerol ester / ether.

[0066] In a further solution, the molar ratio of the monoglyceride / ether to glycidyl ester / ether of the present invention is 1.0:1.0-5.0.

[0067] In the present invention, the inventor has studied the selection of catalysis, and found in the research process that: when using inorganic bases such as...

Embodiment 1

[0102] The preparation of catalyst, concrete steps are as follows:

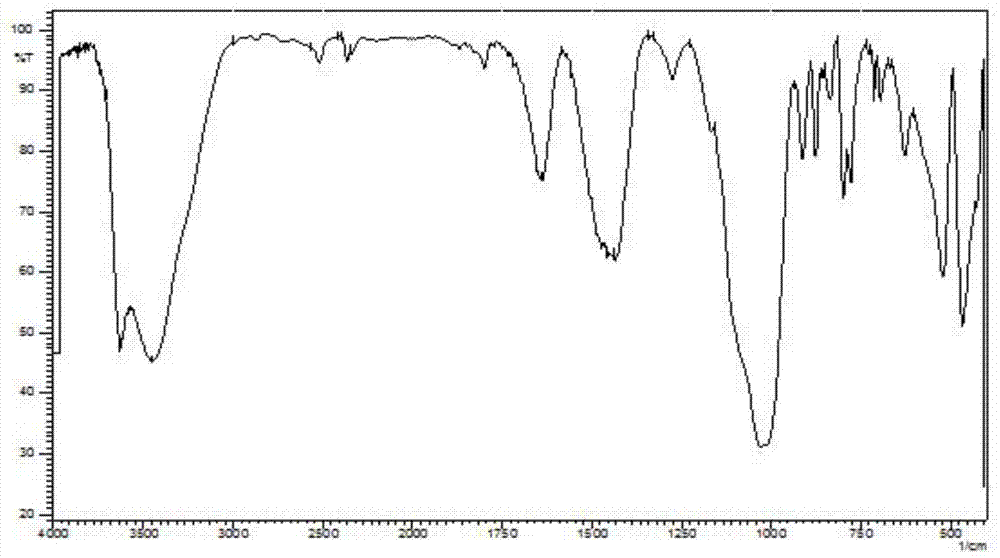

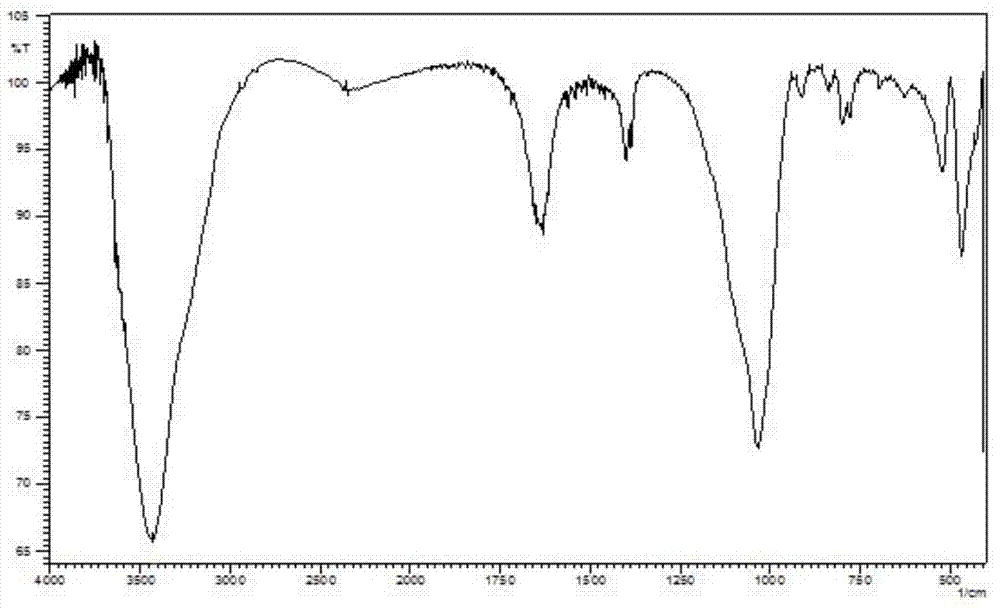

[0103] 1) Acidified modified bentonite: Weigh 600g of sodium-based bentonite (infrared spectrogram as attached figure 2 , 1434cm -1 The place is the absorption peak of carbonate), put it into a 5000mL large beaker with 4000mL deionized water in batches, stir until it is completely dispersed; put 400g of 1+1 hydrochloric acid in batches (200g hydrochloric acid dissolved in 200mL deionized water ), to no longer emit air bubbles in the system, the measured pH value is 6, stop stirring, and place overnight. Remove the salt-containing clear liquid in the upper layer, centrifuge the product in the lower layer, wash twice with deionized water, and centrifuge again to obtain a modified bentonite with a moisture content of about 50%; take part of the acidified modified bentonite and dry it at 120 ° C for 24 hours, crush it, and measure it by infrared spectrum, get figure 2 The infrared spectrum shown, 1434cm -1 ...

Embodiment 2

[0108] A kind of oligomeric neodecanoin, the synthetic method is as follows:

[0109] 1) Preparation of monoglyceride neodecanoate: Glycidyl neodecanoate was used as raw material, and hydrolyzed under the action of a hydrolysis catalyst; for the catalyst prepared in Catalyst Example 1, the addition amount of the hydrolysis catalyst in the reaction was 5%; 1250g glycidyl neodecanoate was put into a 2000mL four-neck flask, stirred, and 62.5g hydrolysis catalyst was added. Nitrogen gas was introduced to replace the air, the temperature was gradually raised to 120°C, and deionized water was added dropwise, and the temperature was maintained at 118-122°C for 12 hours. The end point of the reaction is that the epoxy value of the system is ≤0.01. The content of neodecanoin monoglyceride obtained by centrifugation and refining is ≥60%, and the rest is oligomeric neodecanoin glyceride;

[0110] 2) Synthesis of oligomeric neodecanoic acid glycerides: 750 g of neodecanoic acid monoglyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com