Refrigerator rigid polyurethane foam foaming formula and preparation method thereof

A technology for rigid polyurethane foam and refrigerator, applied in the field of polyurethane materials, can solve the problems of insufficient distribution of polyurethane foam, insufficient flow of polyurethane raw materials, affecting the thermal insulation performance of refrigerators, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The composition of each raw material of the polyurethane foaming system of this embodiment by mass is:

[0028] 100 parts of pure white material;

[0029] 13 parts of foaming agent cyclopentane;

[0030] Polymerized MDI 136 parts.

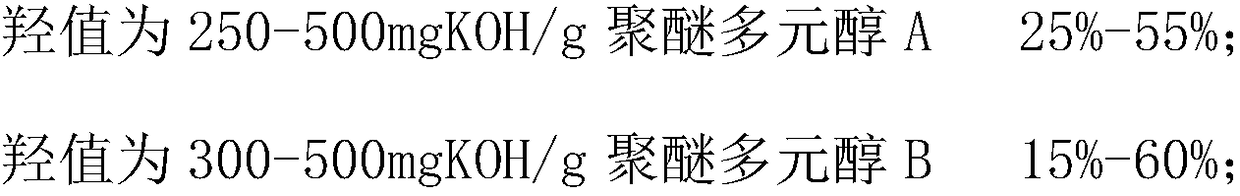

[0031] Wherein the mass fraction of each component of the pure white material is:

[0032]

[0033]

[0034] Described polyether polyol A is the polyether polyol with sorbitol as initiator;

[0035] Described polyether polyol B is the polyether polyol with sucrose and mannitol as initiator;

[0036] The polyether polyol C is an amino polyether polyol with formaldehyde, diethanol and phenol as initiators obtained through the Mann reaction.

[0037] The preparation method comprises the steps of:

[0038] Step 1. Weigh polyether polyol A, polyether polyol B, polyether polyol C, catalyst and surfactant according to the formula and physically mix them into a pure white material;

[0039] Step 2. Mix pure white material and physical bl...

Embodiment 2

[0044] The composition of each raw material of the polyurethane foaming system of this embodiment by mass is:

[0045] 100 parts of pure white material;

[0046] 13 parts of foaming agent cyclopentane;

[0047] Polymerized MDI 136 parts.

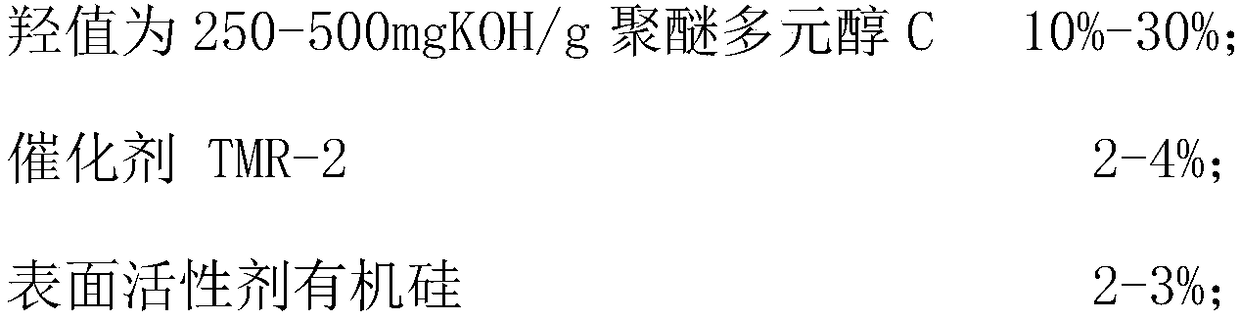

[0048] Wherein the mass fraction of each component of the pure white material is:

[0049]

[0050] Described polyether polyol A is the polyether polyol with sorbitol as initiator;

[0051] Described polyether polyol B is the polyether polyol with sucrose and mannitol as initiator;

[0052] The polyether polyol C is an amino polyether polyol with formaldehyde, diethanol and phenol as initiators obtained through the Mann reaction.

[0053] Utilizing the polyurethane foaming system of this embodiment, the method for manufacturing the heat-insulating rigid polyurethane foam in the refrigerator box is the same as that of Embodiment 1.

[0054] After the foam box was cooled to room temperature, the rigid polyurethane foam in the box was t...

Embodiment 3

[0056] The composition of each raw material of the polyurethane foaming system of this embodiment by mass is:

[0057] 100 parts of pure white material;

[0058] 13 parts of foaming agent cyclopentane;

[0059] Polymerized MDI 136 parts.

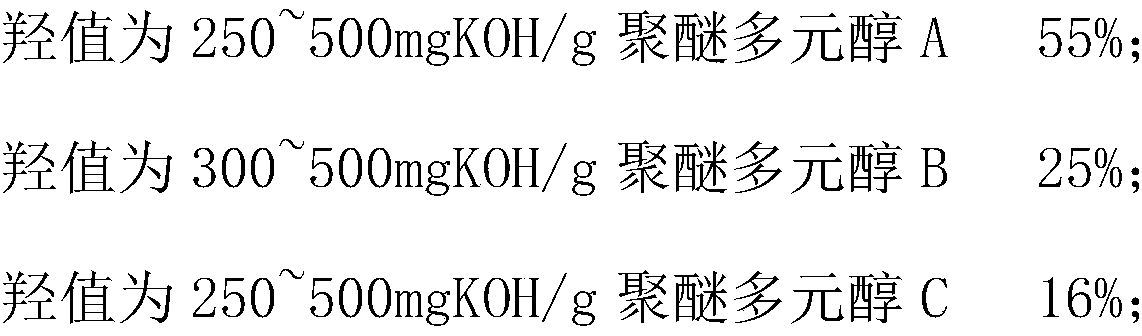

[0060] Wherein the mass fraction of each component of the pure white material is:

[0061]

[0062]

[0063] Described polyether polyol A is the polyether polyol with sorbitol as initiator;

[0064] Described polyether polyol B is the polyether polyol with sucrose and mannitol as initiator;

[0065] The polyether polyol C is an amino polyether polyol with formaldehyde, diethanol and phenol as initiators obtained through the Mann reaction.

[0066] Utilizing the polyurethane foaming system of this embodiment, the method for manufacturing the heat-insulating rigid polyurethane foam in the refrigerator box is the same as that of Embodiment 1.

[0067] After the foam box was cooled to room temperature, the rigid polyurethane foam in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com