Prefabricated reinforced concrete building

A reinforced concrete and prefabricated technology, which is applied in the direction of architecture and building construction, can solve the problems of poor reliability of node connections, high construction and maintenance costs, and restrictions on market promotion, so as to improve building assembly rate, improve construction efficiency, Effect of improving earthquake resistance and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

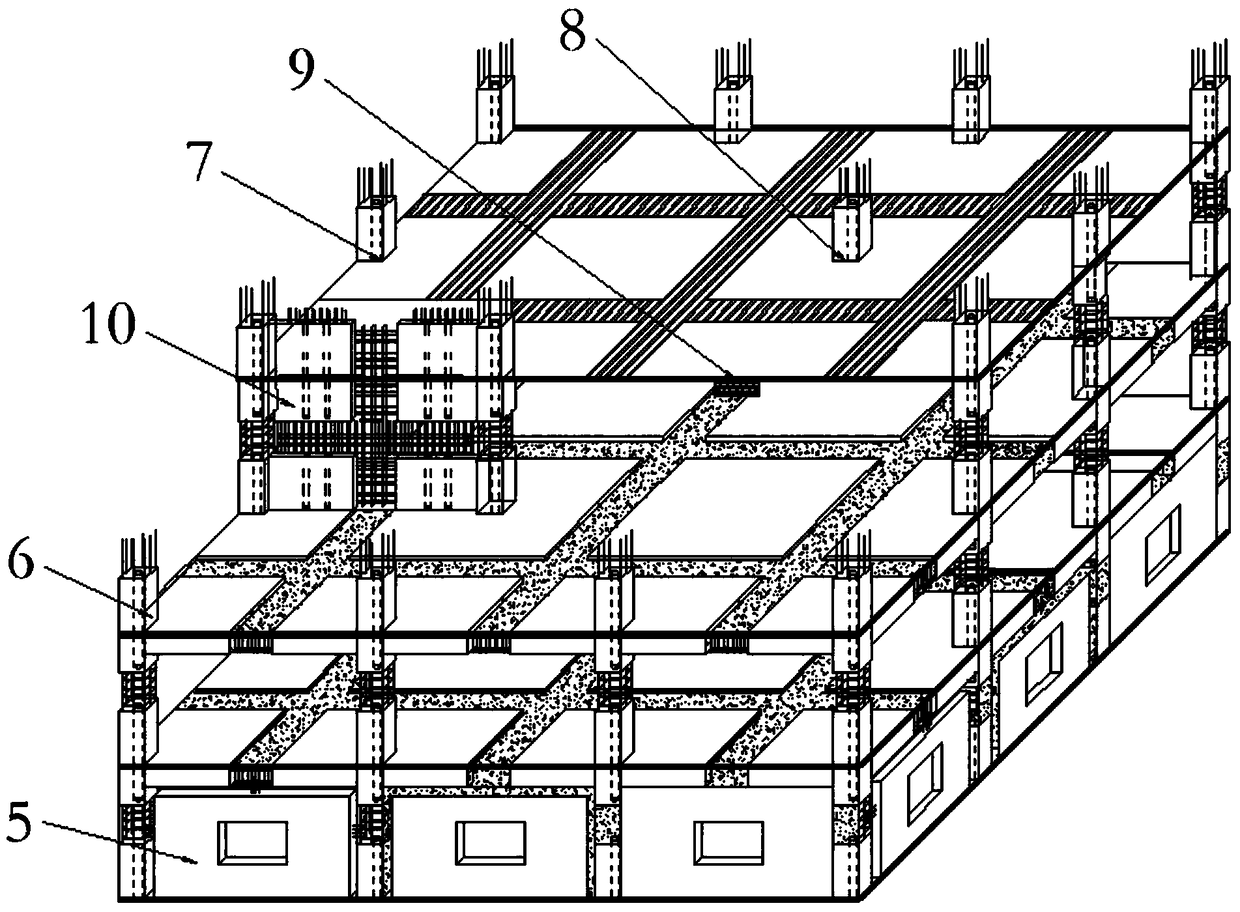

[0040] Embodiment 1, see Figure 1-Figure 11 , a prefabricated reinforced concrete building, comprising a wall 5, a corner column combination 6, a side column combination 7, a central column combination 8, a plate beam combination 9 and a shear wall combination 10, wherein: the wall 5 includes an outer wall 5-1 and an inner wall Wall 5-2, the outer wall 5-1 can be provided with a window opening 11, and the inner wall 5-2 can be provided with a door opening;

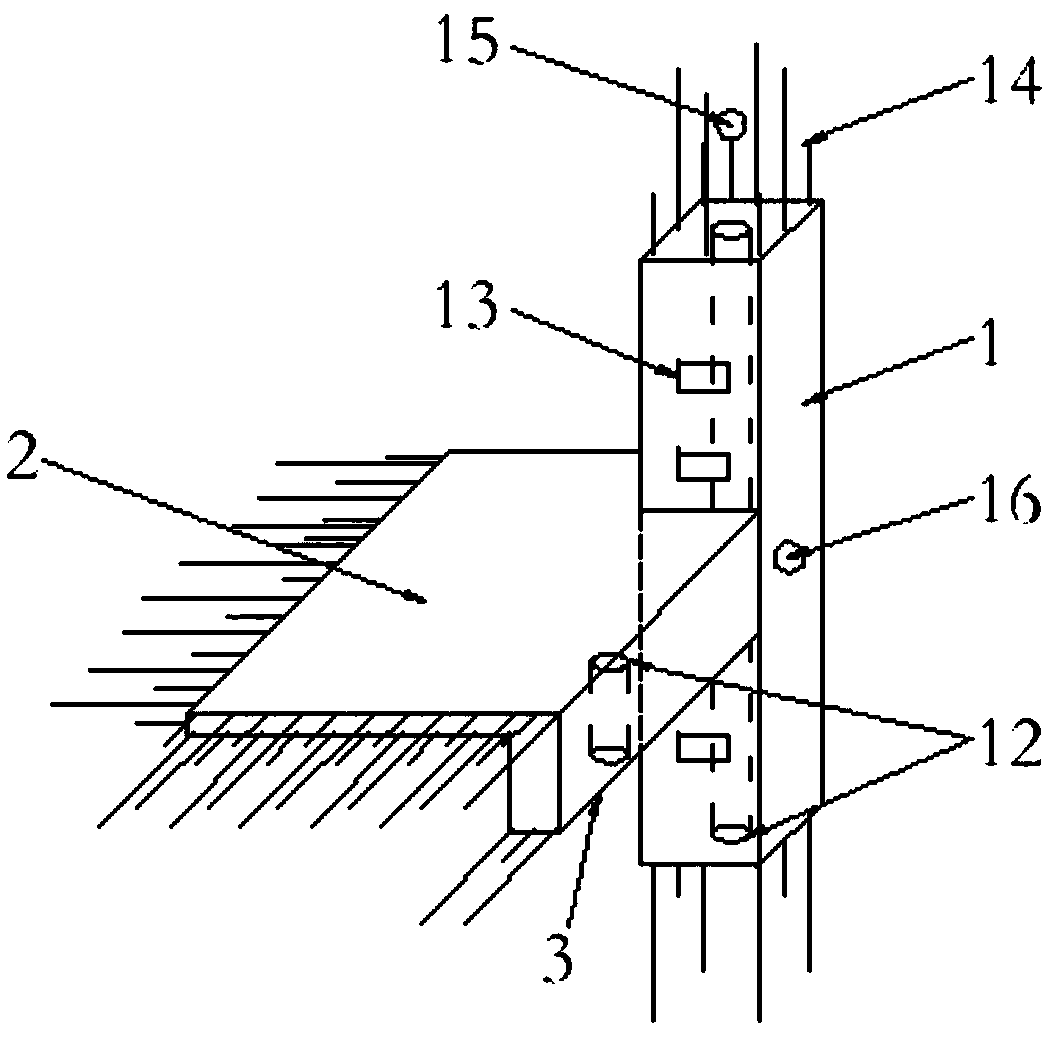

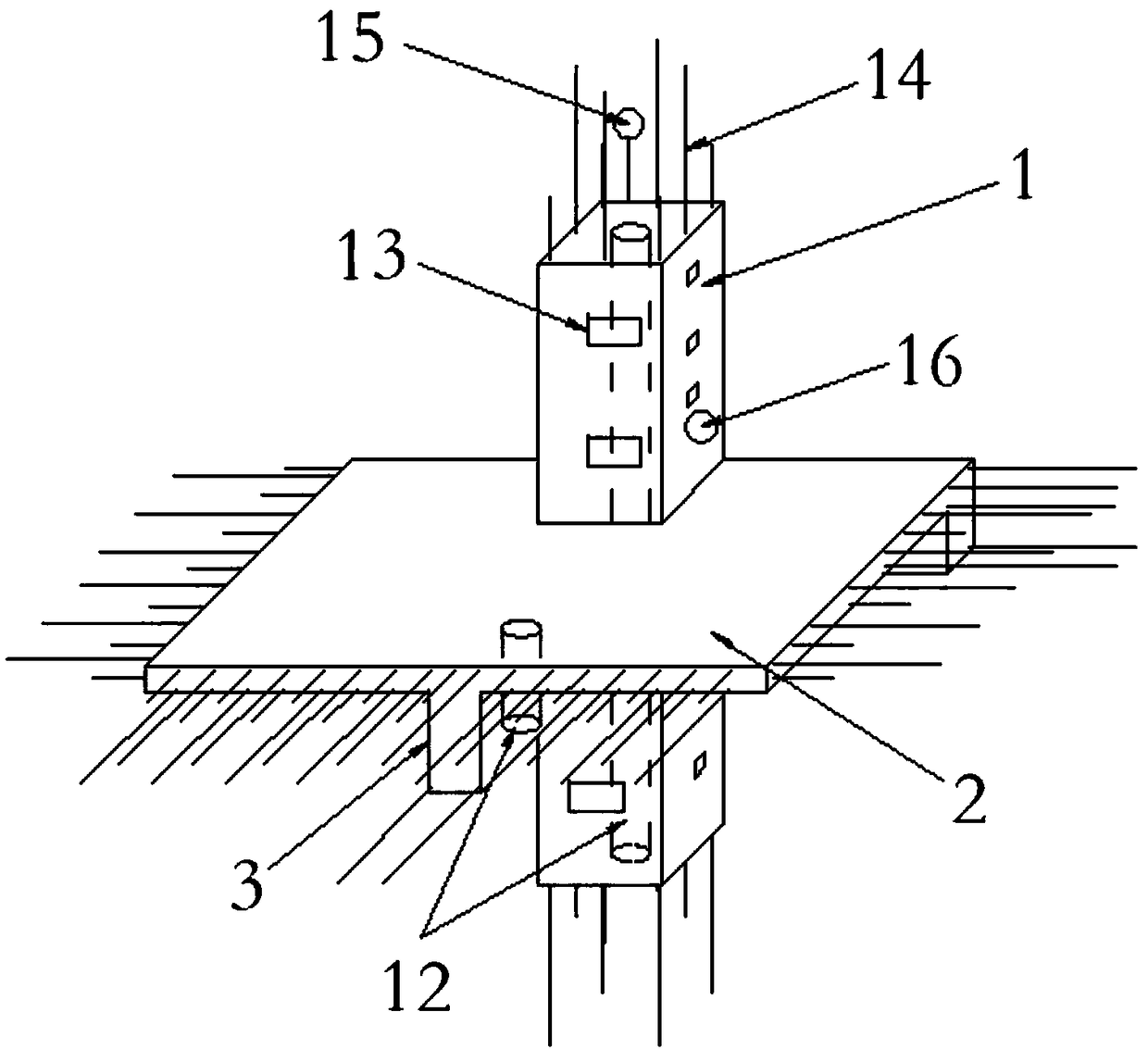

[0041] The corner column combination 6 includes a column 1, a floor 2 and a beam 3, the column 1 is fixedly installed at the junction of the two sides of the floor 2, and the bottom of the two sides of the floor 2 is provided with a beam 3;

[0042] The side column combination 7 includes a column 1, a floor 2 and a beam 3, the column 1 is fixed in the middle of one side of the floor 2, the bottom of the floor 2 is provided with a beam 3, and one end of the beam 3 is fixedly connected to the column 1;

[0043] The central...

Embodiment 2

[0048] Embodiment 2. A prefabricated reinforced concrete building, wherein: the cross-section of the column 1 and the beam 3 can be designed as rectangle, I-shape, T-shape, cross-shape, L-shape or circle. All the other are with embodiment 1.

Embodiment 3

[0049] Example 3, see Figure 7-Figure 11 , a prefabricated reinforced concrete building, wherein: the exterior wall 5-1 and the interior wall 5-2 use integral formwork to make an integrated interior and exterior wall without painting, and the exterior wall 5-1 and interior wall 5-2 include detailed The stone concrete sandwich panel 5-3 and the insulation layer 5-5, the fine stone concrete sandwich panel 5-3 passing through the insulation layer 5-5 are evenly provided with reliable connectors 5-4 to form a whole, which can effectively reduce the engineering cost, improve the seismic performance and Fire resistance, energy saving and environmental protection while ensuring the structural strength of the building. All the other are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap