A mud squeezing device for rectification of pipe jacking machine and rectification method thereof

A pipe jacking machine and thick mud technology, applied in vertical well equipment, earthwork drilling, wellbore lining, etc., can solve the problems of limited jacking force, high cost of deviation correction cylinder, inability to carry out accurate deviation correction, etc., so as to enhance the reaction force and structure. Simple and compact, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

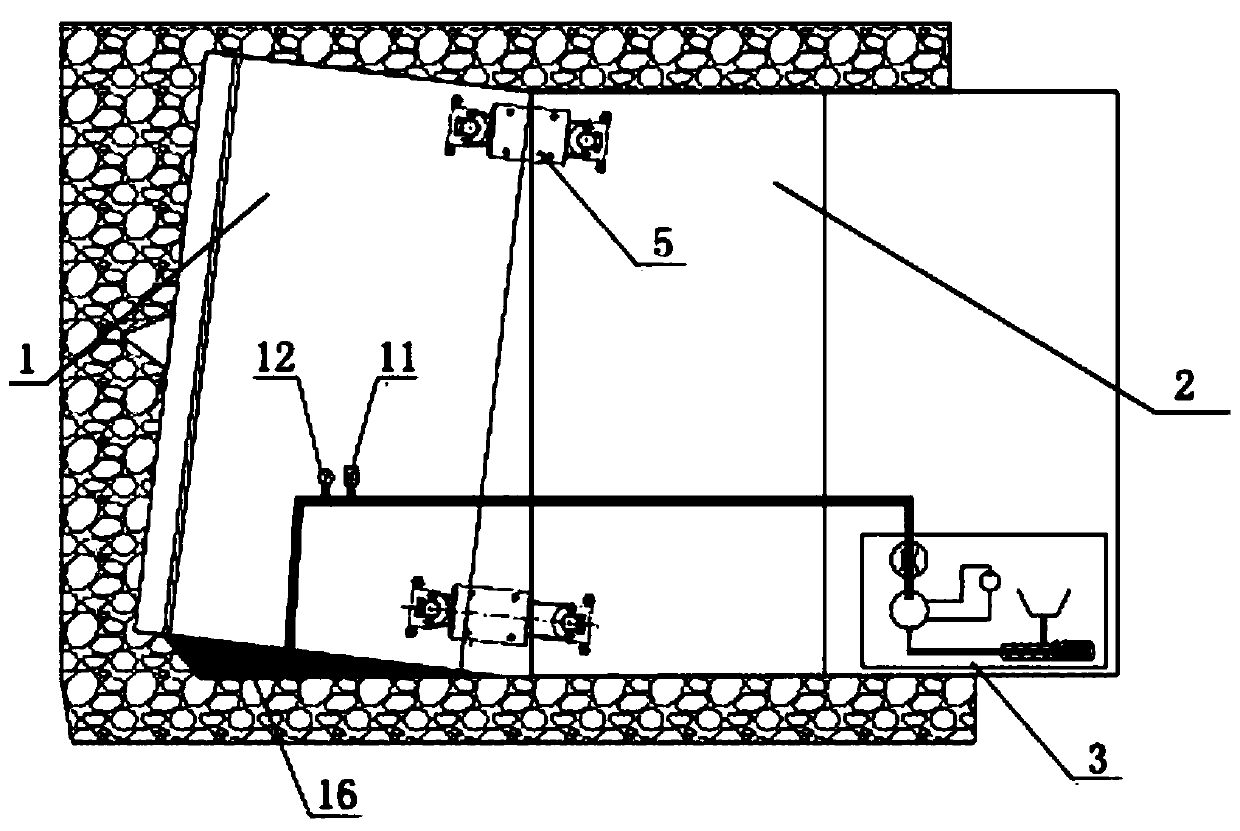

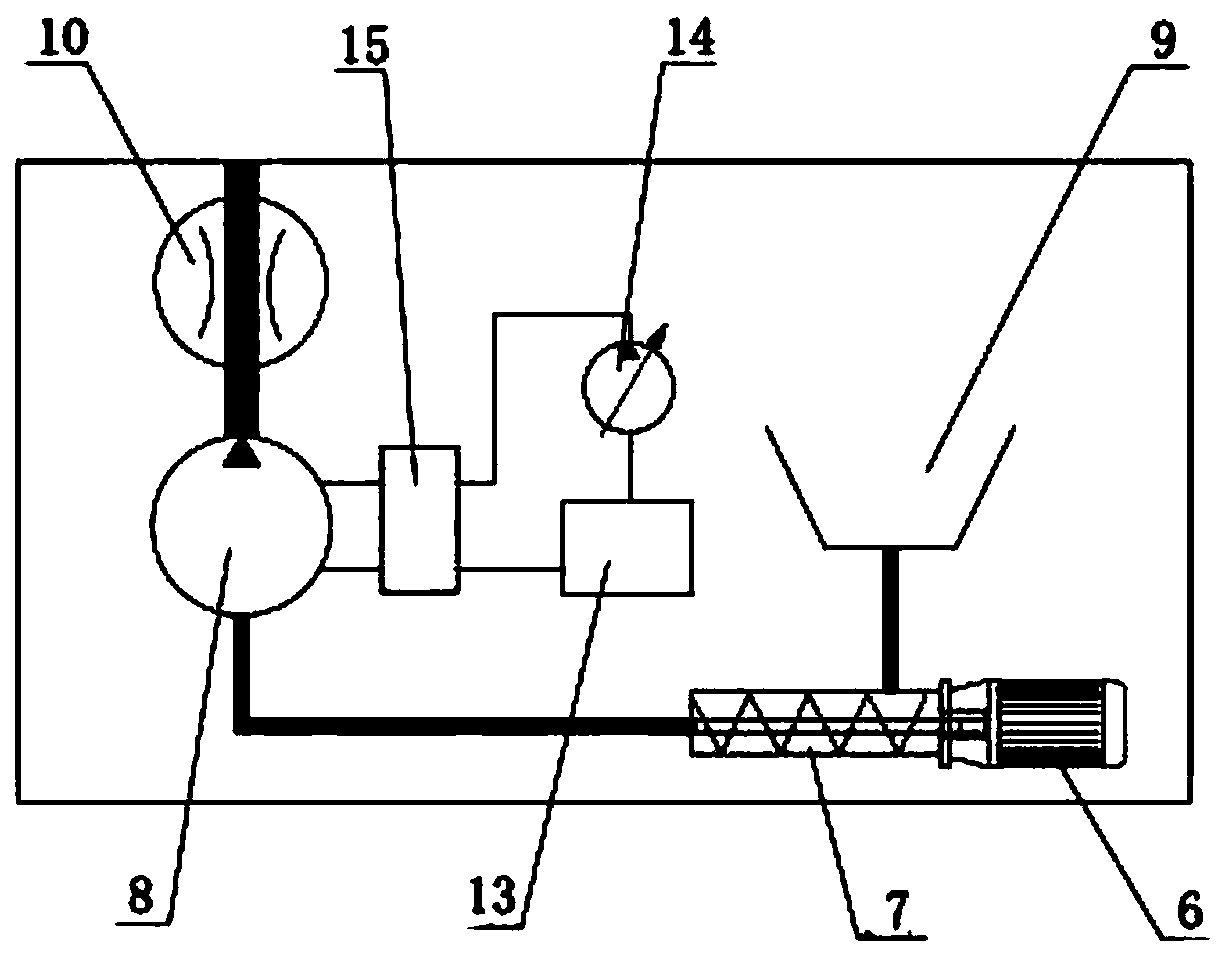

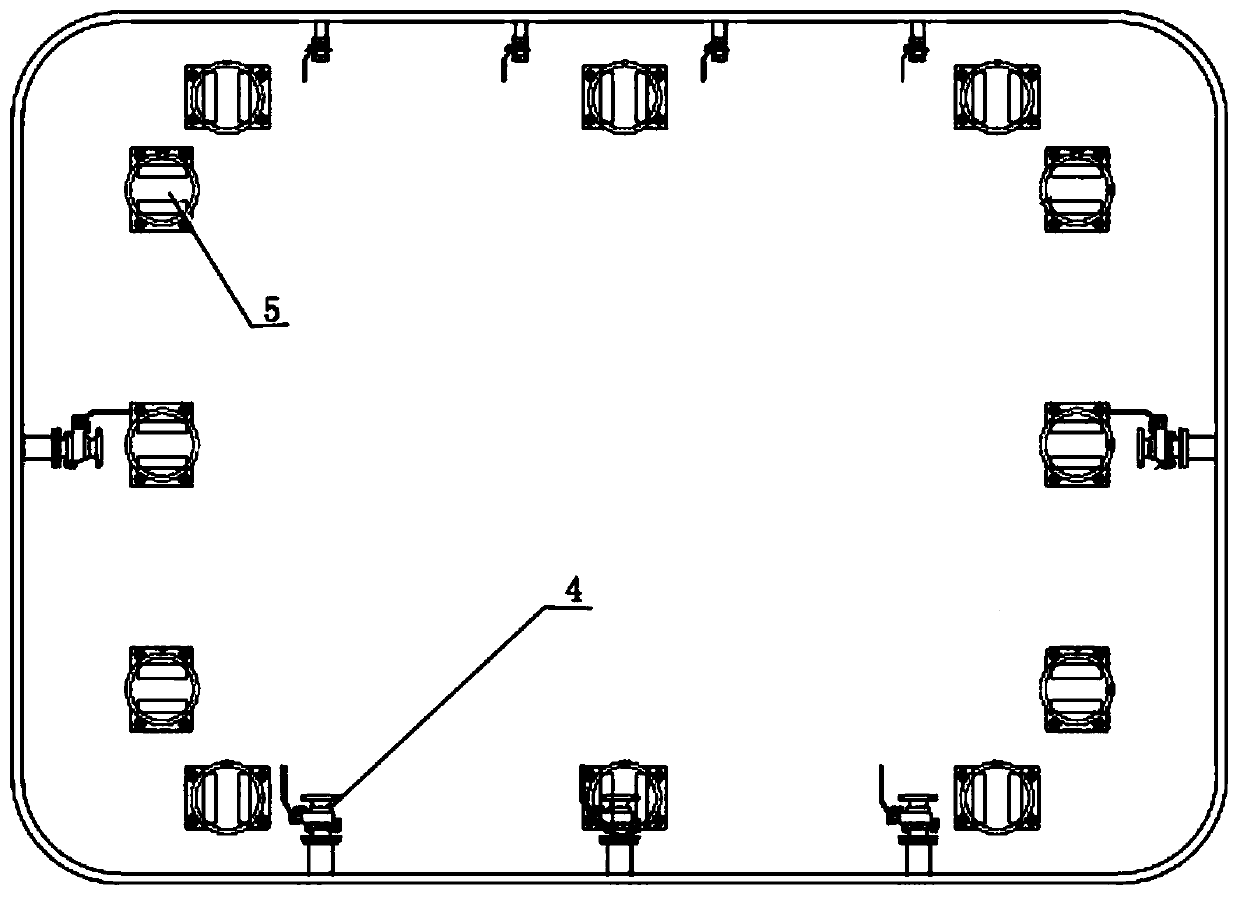

[0027] Such as figure 1 , figure 2 As shown, a mud squeezing device for correcting deviation of a pipe jacking machine includes a front shield 1, a back shield 2, a dredging pump system 3, a mud injection port 4 and a hinged device 5, and the mud pumping system 3 includes a motor 6, Stirring screw pump 7, thick mud delivery pump 8 and mud hopper 9, the mud outlet of described mud hopper 9 is connected with stirring screw pump 7 through pipeline, and the stirring shaft of described stirring screw pump 7 is connected with motor 6, and the mixing The mud outlet of the screw pump 7 is connected to the thick mud delivery pump 8 through a pipeline, and the mud outlet of the thick mud delivery pump 8 is connected to a plurality of mud injection ports 4 through a pipeline respectively, and the plurality of mud injection ports 4 are respectively set On the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com