Ceramic composite steel pipe

A composite steel pipe and ceramic technology, applied in the field of wear-resistant steel pipe manufacturing, can solve the problems of inconvenient installation and fixation of the wear-resistant pipe, difficult to effectively cover the ceramic lining, and difficulty in heat dissipation of the wear-resistant steel pipe, so as to improve the positioning speed and the connection firmness. , Improve the heat dissipation efficiency in the tube and improve the effect of effective coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

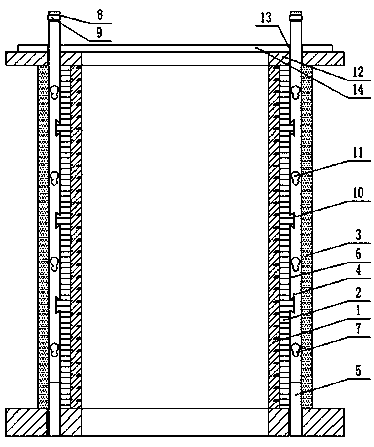

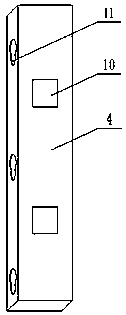

[0020] Such as Figure 1-Figure 2 As shown, the present invention provides a ceramic composite steel pipe, comprising a ceramic inner lining 1, a transition layer 2, and a stainless steel outer pipe 3. The transition layer 2 formed by the ceramic inner lining 1 through the thermite reaction is fixedly connected with the stainless steel outer pipe 3, and the stainless steel outer pipe 3 is fixedly connected. The inner wall of the outer tube 3 is fixed with several convex grooves 4, because the main materials of the corundum ceramic lining 1, the transition layer 2 and the stainless steel outer tube 3 are alumina, iron, and stainless steel respectively, and their thermal conductivity coefficients are high, so it is necessary to pass The convex groove 4 increases the heat exchange area between the outer steel pipe 3 and the transition layer 2, so as to further effectively improve the heat dissipation efficiency; one end of the convex groove 4 protrudes from the side of the stainle...

Embodiment 2

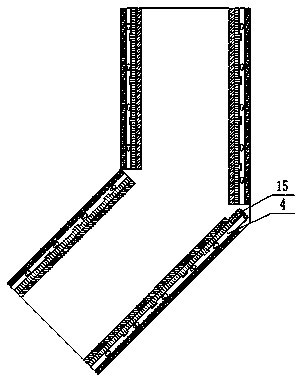

[0024] Such as image 3 As shown, when the present invention is in use, two ceramic composite steel pipes need to be directly welded and fixed at a certain angle. For this non-standard component, there must be a certain inner seam at the connection between the steel pipes, and there is no wear-resistant inner seam on the inner seam. Lining, and the fluid at the corner has a great impact on the inner seam, and the wear degree of the corner is greater, so it is necessary to cover the inner seam with a wear-resistant lining, and arrange the composite pipe below so that the protruding end of the convex groove 4 is upward, Clamp the wear-resistant rubber pad 15 on the protruding end of the convex groove 4, because the thickness of the wear-resistant rubber pad 15 is less than the thickness of the transition layer 2 and the ceramic lining 1, so the installed wear-resistant rubber pad 15 will be stuck in the inner seam, When the upper fluid stays, no matter how the angle of the fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com