A compact projector light source

A technology with a compact structure and projectors, which is applied in the field of projector light sources, can solve the problems of complex optical paths of light sources, large occupied volume, and many lens components, and achieve the effects of high output luminous flux, small occupied volume, and few lens components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

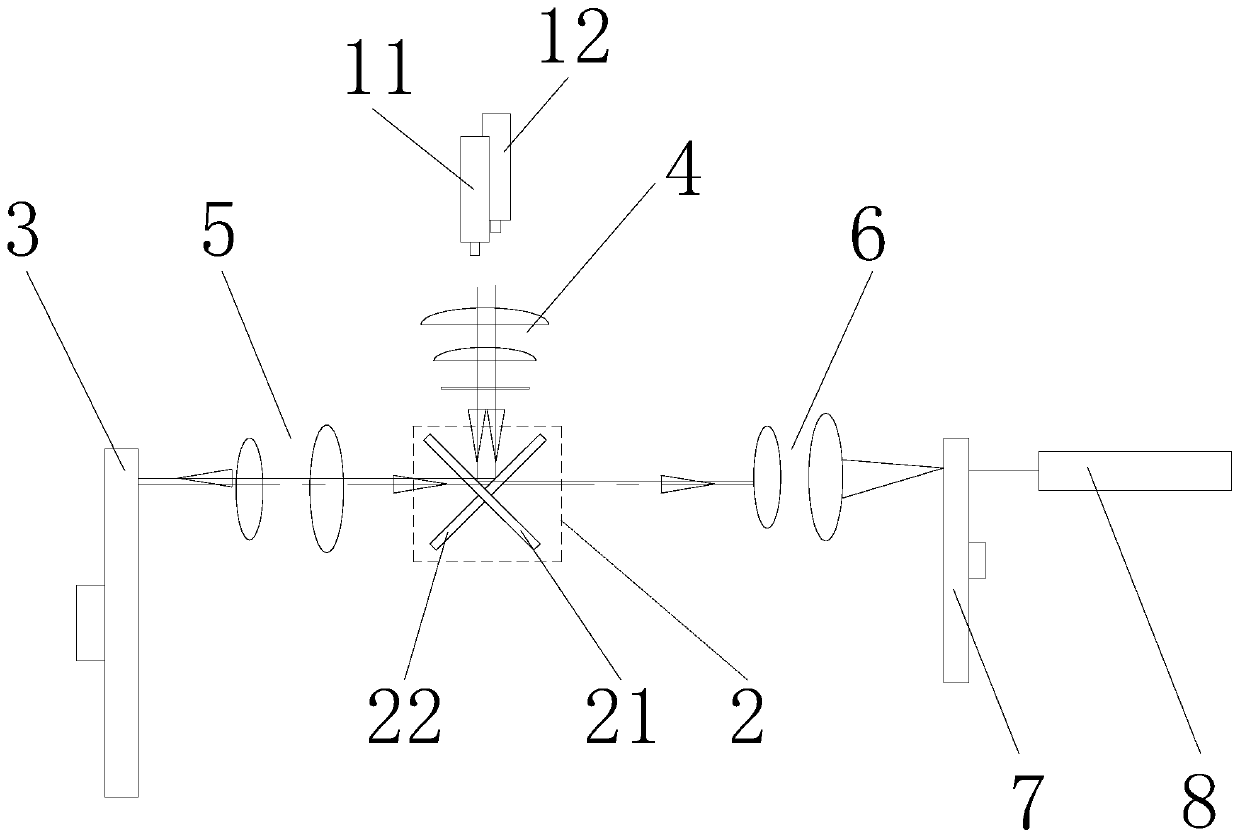

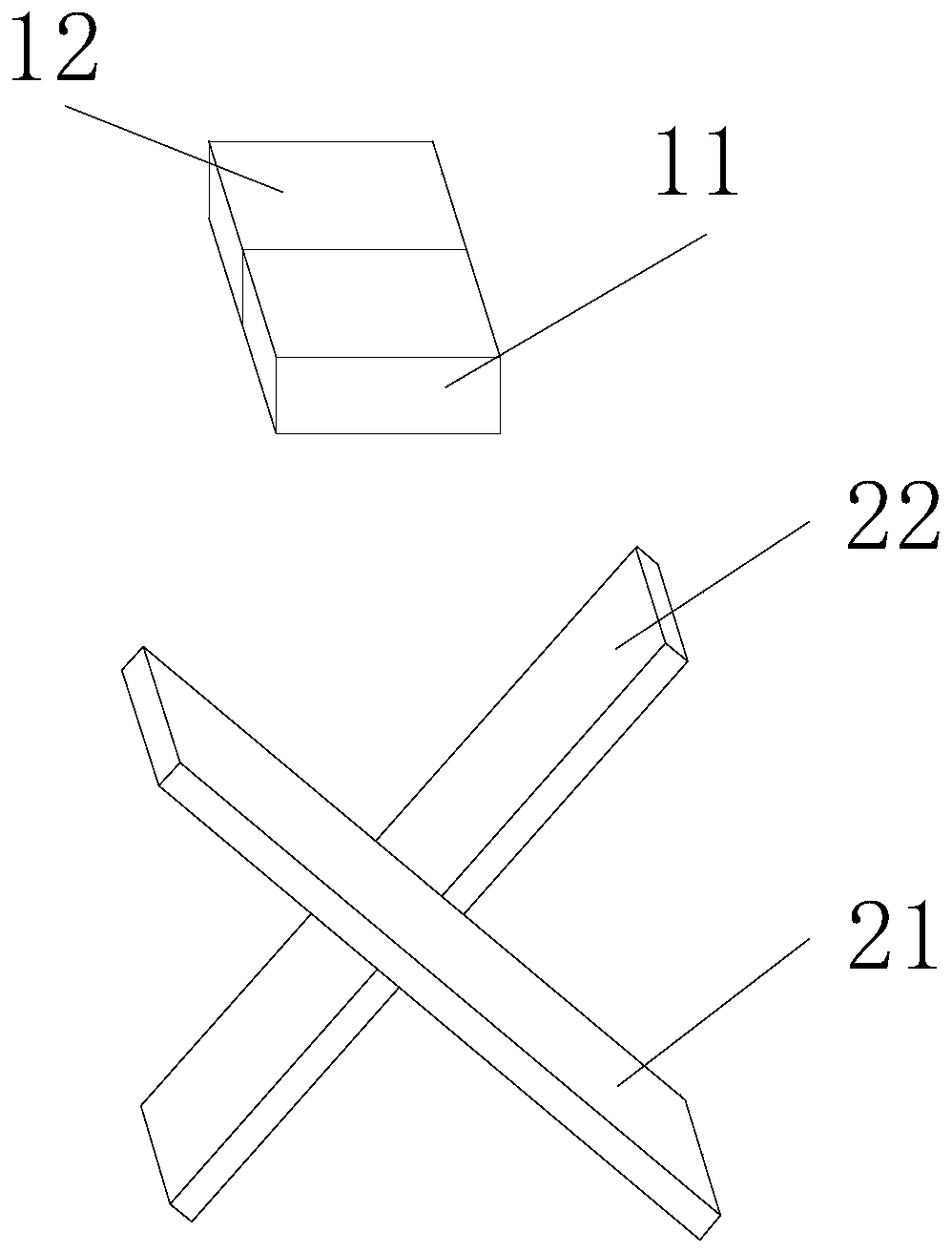

[0032] Such as figure 1 with figure 2 As shown, light source one 11 and light source two 12 all adopt blue lasers, preferably light source one 11 is a blue laser with a main wavelength of 460nm, and light source two 12 is a blue laser with a main wavelength of 445nm; in order to improve structural compactness, light source one 11, The second light source 12 is arranged side by side and the light emitted is in the same direction and parallel. The first lens 21 and the second lens 22 are respectively located on the light path of the light emitted by the first light source 11 and the second light source 12. The first lens 21 is located on the side of the second lens 22, and the second lens The first 21 and the second lens 22 intersect to form an X shape at a certain angle. In this embodiment, the first lens 21 and the second lens 22 are perpendicular to each other, and the second lens 22 reflects blue and transmits other colors. The light emitted by the first light source 11 and...

Embodiment 2

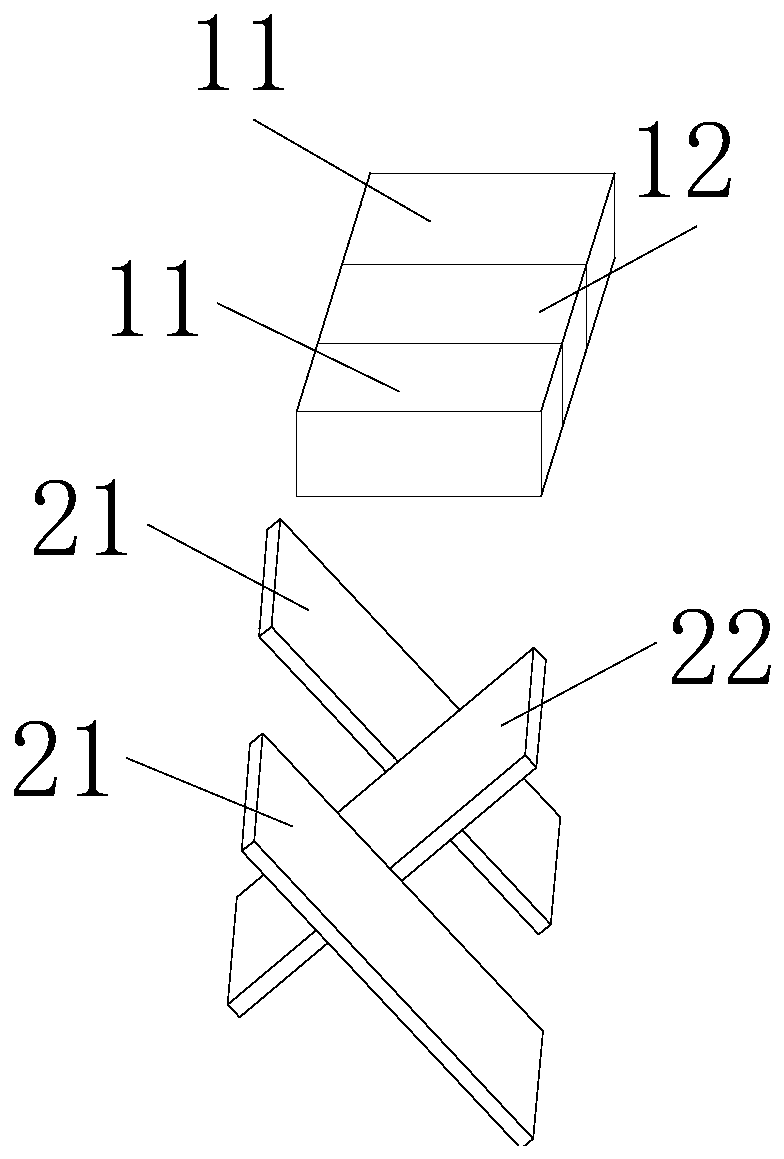

[0046] Such as image 3 As shown, the difference from the first embodiment is that the first light source 11 is arranged symmetrically on both sides of the second light source 12. According to the white balance, the number of lasers on one side of the first light source 11 is half of that of the first light source 11 in the first embodiment. Both sides of 22 are symmetrically provided with lens 1 21, so that the blue laser light in the final output beam is located on both sides of the radiation fluorescence, which solves the problem of no blue light in a part of the area when displayed on the screen in Embodiment 1, and improves the overall picture. uniformity.

Embodiment 3

[0048] Such as Figure 4 As shown, the difference from the first embodiment is that the second lens 22 transmits blue light and reflects other colors;

[0049] The generation process of the blue light part in the output light beam is the same as that of Embodiment 1;

[0050] The red light, green light and yellow light in the output light beam are slightly different from the first embodiment. The light source two 12 emits blue laser light, and after passing through the focus shaping component one 4, it irradiates on the lens two 22 and transmits it to the focus shaping component two. 5. After the blue laser passes through the focusing and shaping component 25, it is irradiated on the fluorescent wheel 3, and the fluorescent wheel 3 rotates at a high speed, thereby exciting and producing radiant fluorescence of various colors;

[0051] When the fluorescent wheel 3 rotates to the red fluorescent powder area and is irradiated by the blue laser light emitted by the light source 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com