ICF (inertial confinement fusion) cryogenic target device and ICF shielding cover opening speed optimization method

A technology for freezing targets and shielding covers, which is applied in the fields of nuclear reactors, nuclear power generation, climate sustainability, etc., can solve the problems of high failure probability, ignition uncertainty, and high cost, so as to improve the probability of one-time success and improve ignition success rate, the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

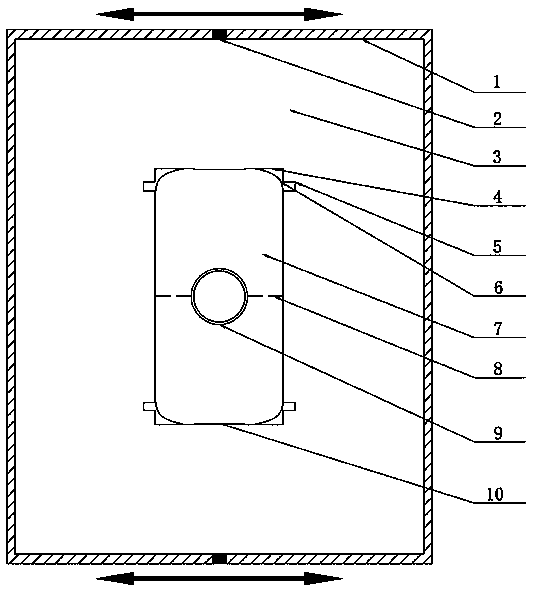

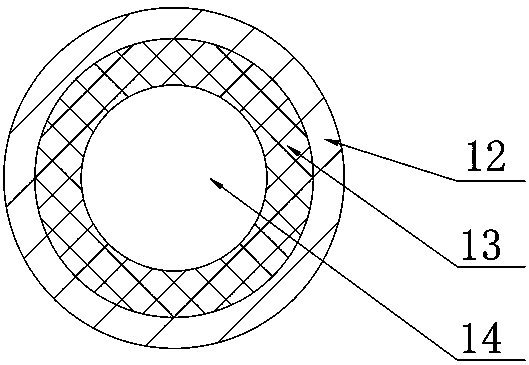

[0025] Embodiment 1: Reference figure 1 , the gold cavity 6 containing the frozen target pellet 9 is located in the thermomechanical structure 4, the laser entrance (LEH) 10 is the window for the laser incident during ignition, the inner diameter of the gold cavity 6 is 5.44mm, the inner height is 10mm, and the thickness is 10μm. The outer side of the gold cavity 6 is a thermomechanical structure 4 made of high-purity aluminum, the material of the outermost shell 12 of the frozen target pellet 9 is hydrocarbon polymer, the outer diameter of the frozen target pellet 9 is 1.16 mm, and the intermediate fuel ice layer 13 is 63 μm thick In the DT ice layer, the innermost fuel gas 14 is DT gas. The frozen target pellet 9 is supported at the center of the structure by a support film 7 made of a polymer film with a thickness of about 0.1 μm. There is a vacuum area 3 between the outer heat radiation shield 1 and the thermomechanical structure 4 , and the heat radiation shield 1 is com...

Embodiment 2

[0032] Embodiment 2: Reference figure 1 , the gold cavity 6 containing the frozen target pellet 9 is located in the thermomechanical structure 4, the laser entrance (LEH) 10 is the window for the laser incident during ignition, the inner diameter of the gold cavity 6 is 5.44mm, the inner height is 10mm, and the thickness is 10μm. The outer side of the gold cavity 6 is a thermomechanical structure 4 made of high-purity aluminum, the material of the outermost shell 12 of the frozen target pellet 9 is hydrocarbon polymer, the outer diameter of the frozen target pellet 9 is 1.16 mm, and the intermediate fuel ice layer 13 is 63 μm thick In the DT ice layer, the innermost fuel gas 14 is DT gas. The frozen target pellet 9 is supported at the center of the structure by a support film 7 made of a polymer film with a thickness of about 0.1 μm. There is a vacuum between the outer heat radiation shield 1 and the thermomechanical structure 4 , and the heat radiation shield 1 is composed o...

Embodiment 3

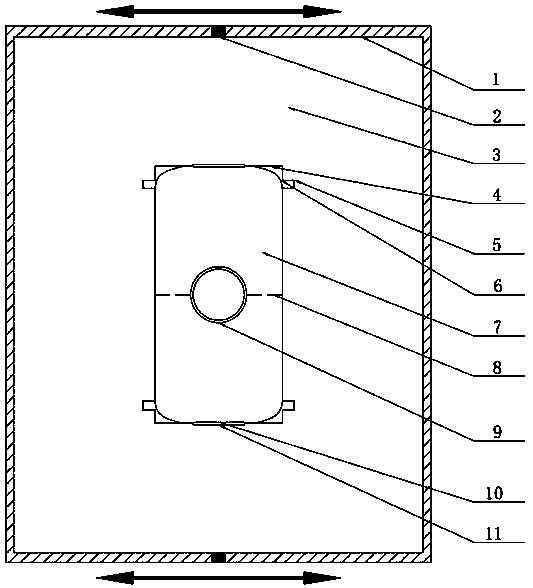

[0039] Embodiment three: reference figure 2 , the gold cavity 6 containing the frozen target pellet 9 is located in the thermomechanical structure 4, the laser entrance (LEH) 10 is the window for the laser incident during ignition, and the absorption rate is 0.9, and there is a storm window 11 outside the laser entrance (LEH) 10, Its absorption rate is 0.9, the inner diameter of the gold cavity 6 is 5.44 mm, the inner height is 10 mm, and the thickness is 10 μm. The outer side of the gold cavity 6 is a thermomechanical structure 4 made of high-purity aluminum, the material of the outermost shell 12 of the frozen target pellet 9 is hydrocarbon polymer, the outer diameter of the frozen target pellet 9 is 1.16 mm, and the intermediate fuel ice layer 13 is 63 μm thick In the DT ice layer, the innermost fuel gas 14 is DT gas. The frozen target pellet 9 is supported at the center of the structure by a support film 7 made of a polymer film with a thickness of about 0.1 μm. There i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Internal height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com