N-type pbse-pbs based thermoelectric material and preparation method thereof

A thermoelectric material, n-type technology, applied in the direction of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc., can solve problems such as difficulty in individual regulation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

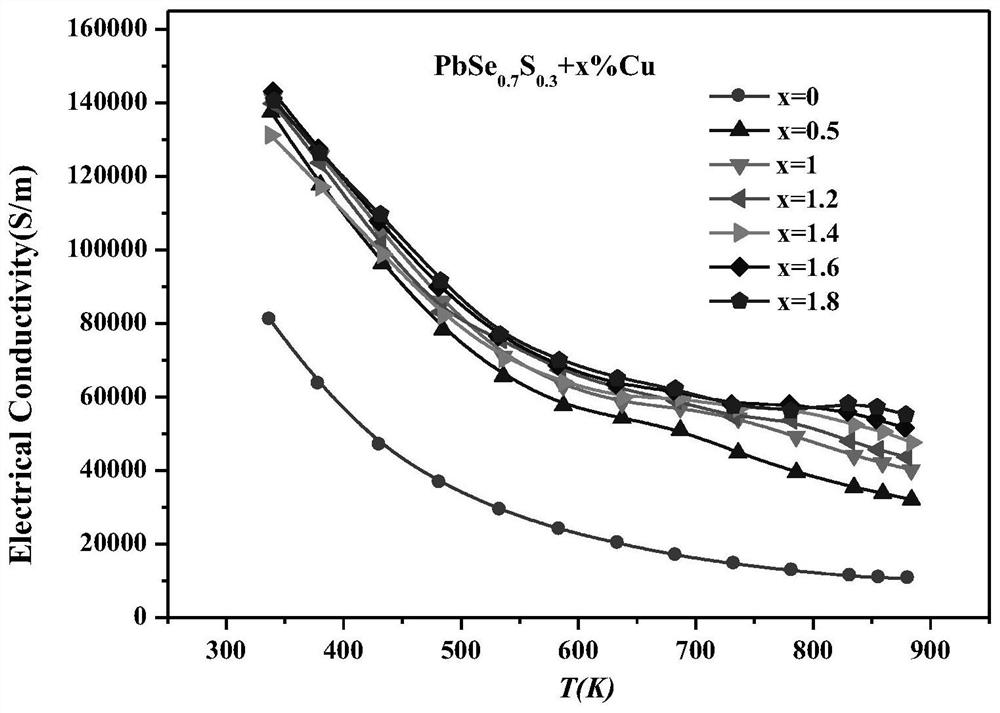

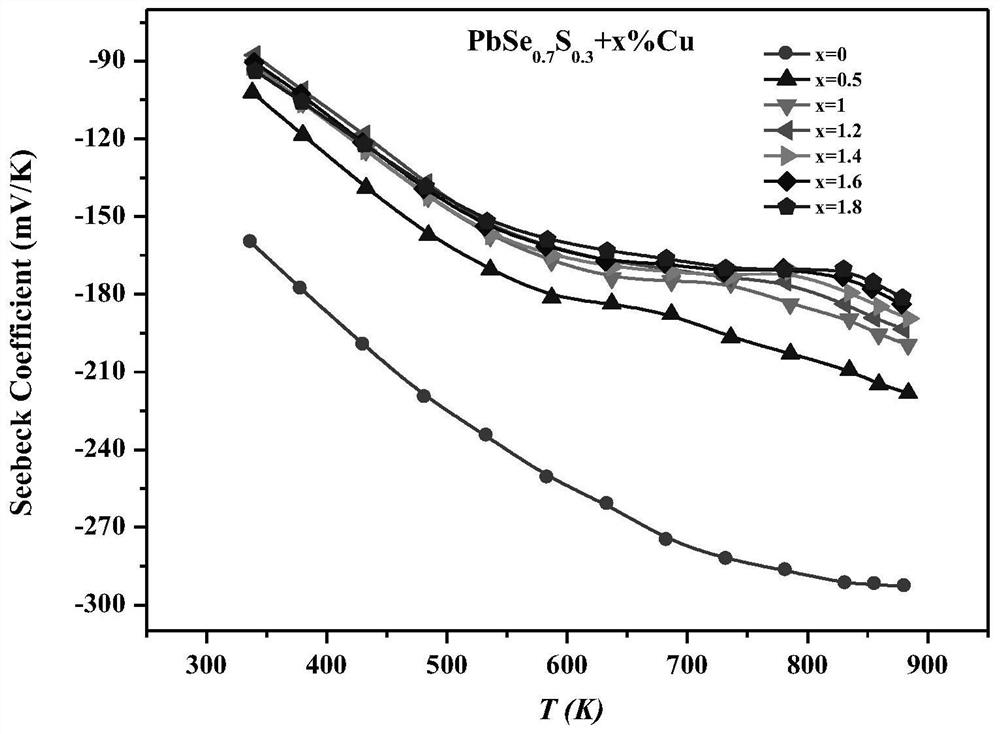

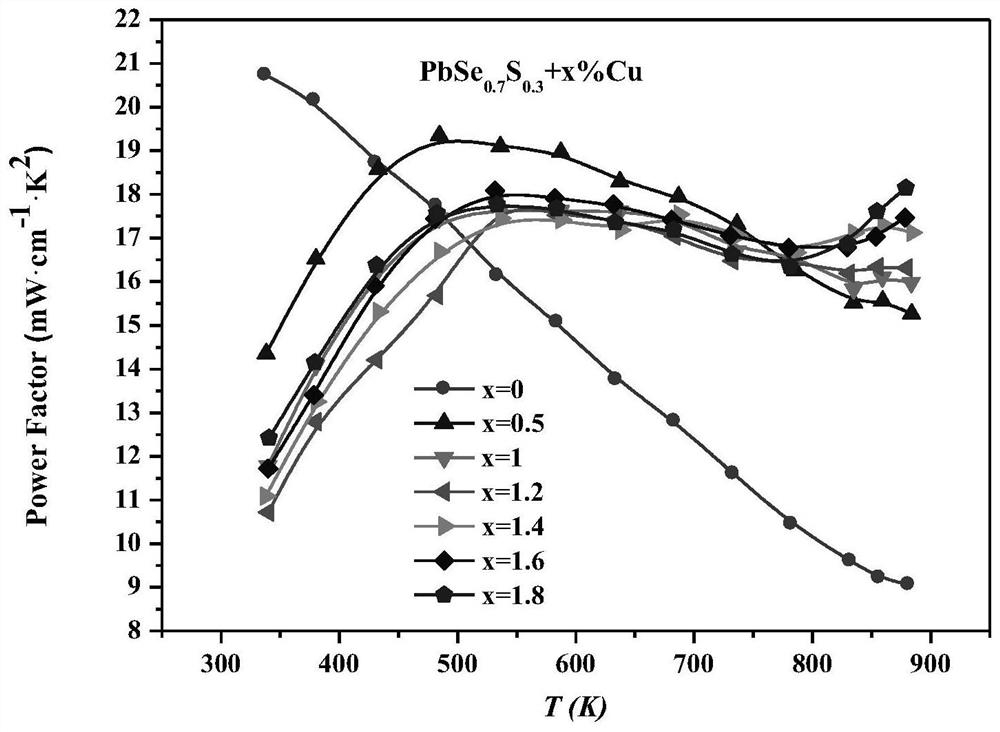

[0032] In this embodiment, an n-type PbSe-PbS based thermoelectric material, the chemical formula of which is PbSe 0.7 S 0.3 Cu x , x are 0, 0.005, 0.01, 0.012, 0.014, 0.016, 0.018 respectively, that is, in this embodiment, an n-type PbSe-PbS based thermoelectric material has the chemical formula PbSe 0.7 S 0.3 , PbSe 0.7 S 0.3 Cu 0.005 , PbSe 0.7 S 0.3 Cu 0.01 , PbSe 0.7 S 0.3 Cu 0.012 , PbSe 0.7 S 0.3 Cu 0.014 , PbSe 0.7 S 0.3 Cu 0.016 , PbSe 0.7 S 0.3 Cu 0.018 a series of materials.

[0033] In this embodiment, a method for preparing an n-type PbSe-PbS-based thermoelectric material includes the following steps:

[0034] a. In a glove box filled with Ar gas, use Pb grains, Se powder, S powder and Cu powder with a purity of 99.99% as raw materials, and prepare the target material according to the chemical formula PbSe 0.7 S 0.3 Cu x Weigh 6g of each raw material component in total, prepare the raw materials with Pb, Se, S and Cu in a molar ratio of 1:0.7...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this embodiment, an n-type PbSe-PbS based thermoelectric material, the chemical formula of which is PbSe 0.7 S 0.3 Cu x , x are 0, 0.005, 0.01, 0.012, 0.014, 0.016, 0.018 respectively, that is, in this embodiment, an n-type PbSe-PbS based thermoelectric material has the chemical formula PbSe 0.7 S 0.3 , PbSe 0.7 S 0.3 Cu 0.005 , PbSe 0.7 S 0.3 Cu 0.01 , PbSe 0.7 S 0.3 Cu 0.012 , PbSe 0.7 S 0.3Cu 0.014 , PbSe 0.7 S 0.3 Cu 0.016 , PbSe 0.7 S 0.3 Cu 0.018 a series of materials. The n-type PbSe-PbS based thermoelectric material of this embodiment is the same as that of Embodiment 1, only the process conditions of the preparation method are different.

[0046] In this embodiment, a method for preparing an n-type PbSe-PbS-based thermoelectric material includes the following steps:

[0047] a. This step is the same as in Embodiment 1;

[0048] b. This step is the same...

Embodiment 3

[0053] This embodiment is basically the same as the previous embodiment, and the special features are:

[0054] In this embodiment, an n-type PbSe-PbS based thermoelectric material, the chemical formula of which is PbSe 0.7 S 0.3 Cu x , x are 0, 0.005, 0.01, 0.012, 0.014, 0.016, 0.018 respectively, that is, in this embodiment, an n-type PbSe-PbS based thermoelectric material has the chemical formula PbSe 0.7 S 0.3 , PbSe 0.7 S 0.3 Cu 0.005 , PbSe 0.7 S 0.3 Cu 0.01 , PbSe 0.7 S 0.3 Cu 0.012 , PbSe 0.7 S 0.3 Cu 0.014 , PbSe 0.7 S 0.3 Cu 0.016 , PbSe 0.7 S 0.3 Cu 0.018 a series of materials. The n-type PbSe-PbS based thermoelectric material of this embodiment is the same as that of Embodiment 1, only the process conditions of the preparation method are different.

[0055] In this embodiment, a method for preparing an n-type PbSe-PbS-based thermoelectric material includes the following steps:

[0056] a. This step is the same as in Embodiment 1;

[0057] b....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com