Double-reflecting surface antenna with special shape guided wave dielectric rod feeding

A special shape, double reflector technology, applied in antenna, antenna grounding switch structure connection, circuit, etc., can solve the problem of reducing antenna efficiency, high cross-plan and beam tilt, affecting high-order mode sidelobe level and cross-polarization, etc. problem, to achieve the effect of symmetrical structure, small size and low impedance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

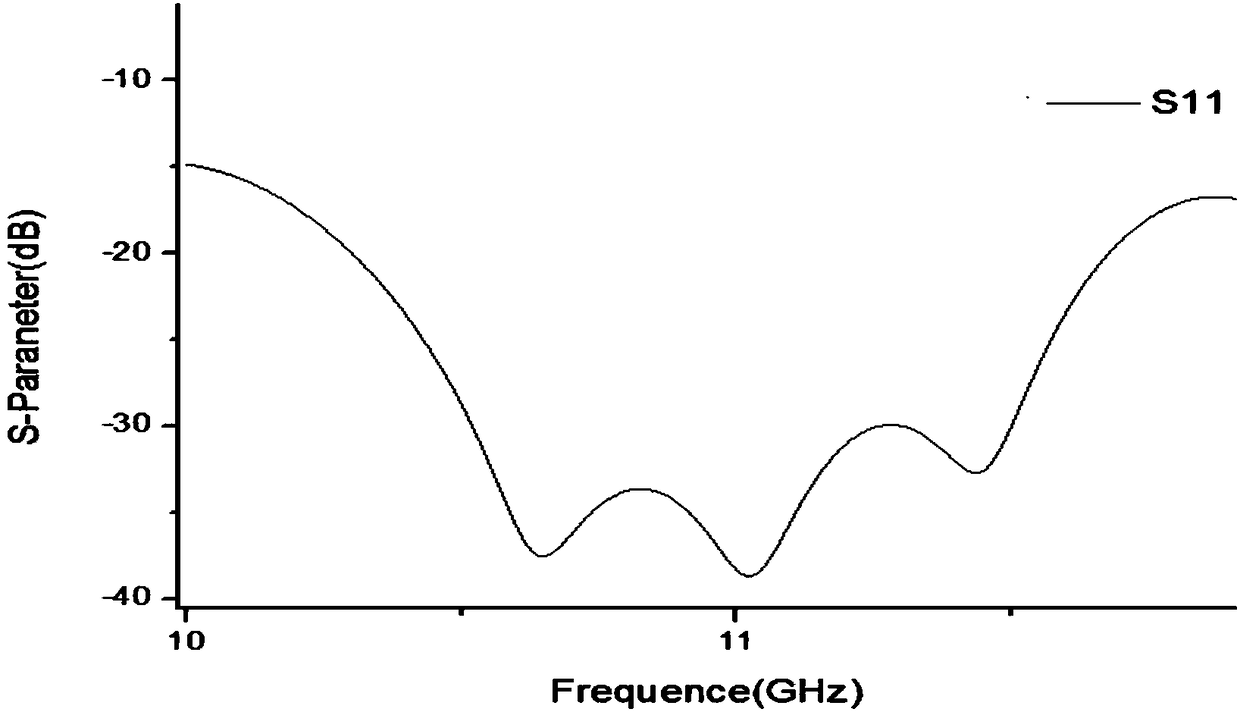

[0033] Before giving the entire parabolic reflector antenna, we give the design and optimization of the matching feed: the antenna works at 10.40GHz to 11.33GHz.

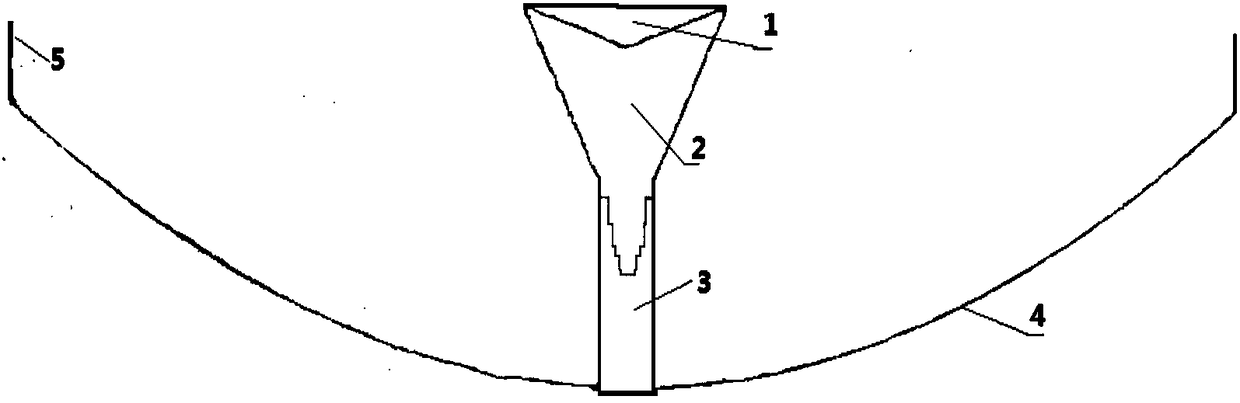

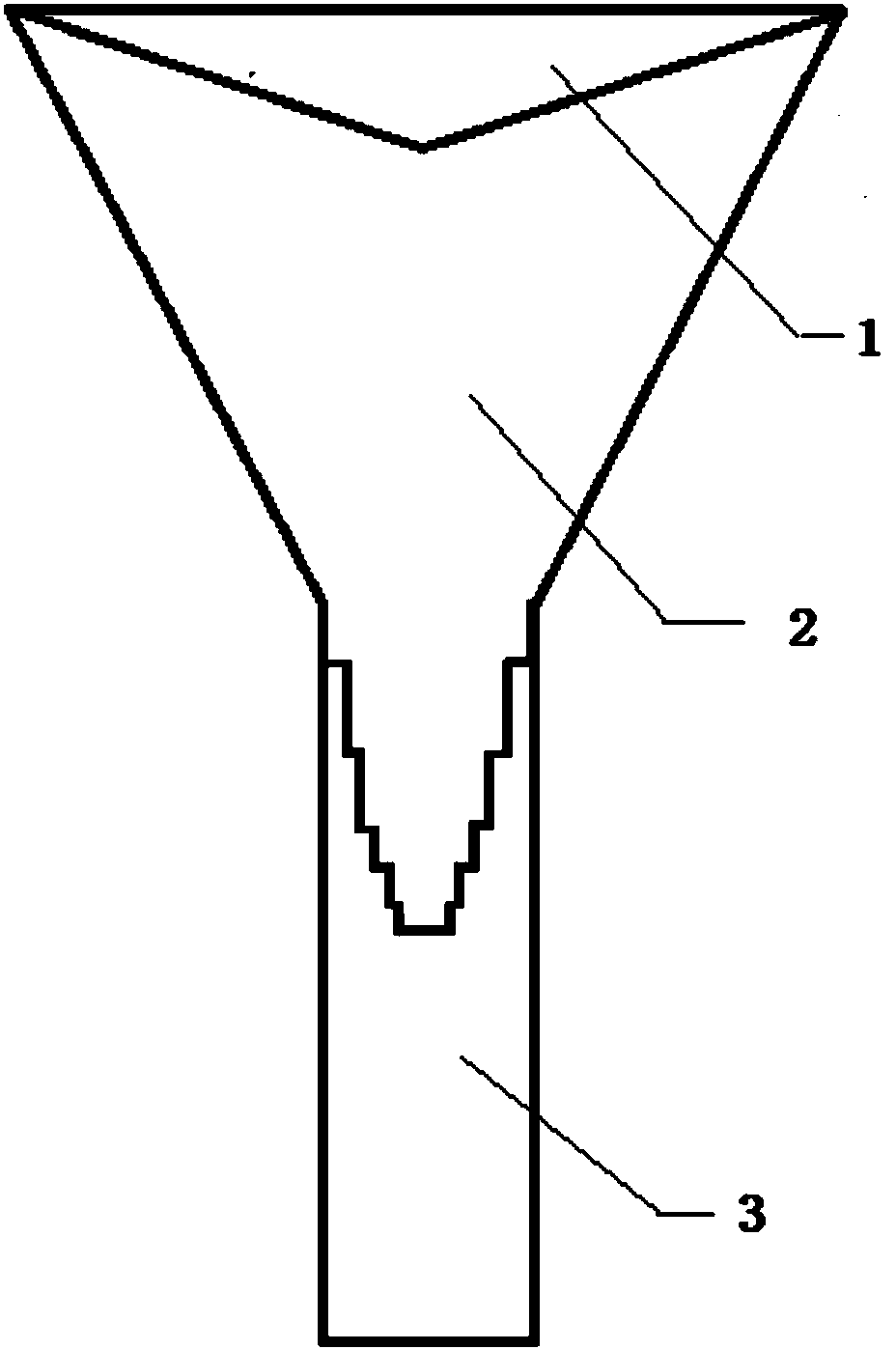

[0034] In the example design made, the size of the selected double reflector antenna is 600mm in diameter, the operating frequency of the double reflector antenna is 10.40GHz-11.33GHz, the inner diameter of the circular waveguide is 12.5mm, the length is 89mm, and the secondary reflector Dimensions: the diameter of the circular platform is 100mm, and the height is 17.5mm; its center is located near the focus of the paraboloid. By adjusting the value of the distance t between the vertex of the parabolic reflector 4 and the conical secondary reflector 1 , the phase center of the feed can be moved to the focal point of the paraboloid reflector 4 .

[0035] The ground diameter of the dielectric circular table is 100mm and the upper table diameter is 12.5mm. The height of the circular table just connects the circular wav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com