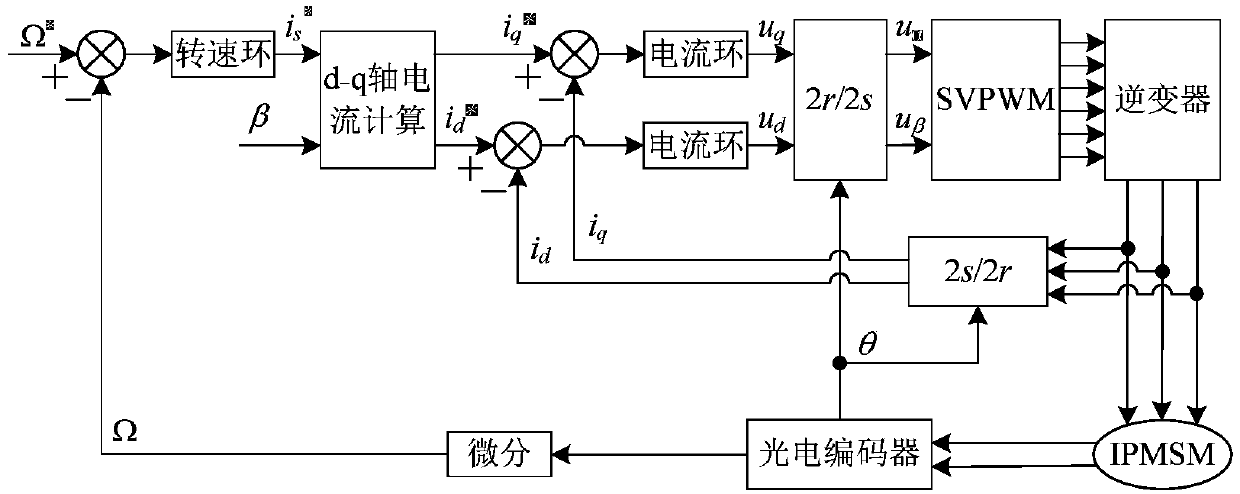

Optimal torque angle control system of built-in permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and control system, applied in control system, vector control system, motor generator control and other directions, can solve problems such as poor control accuracy, and achieve the effect of simple control method, strong robustness and dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

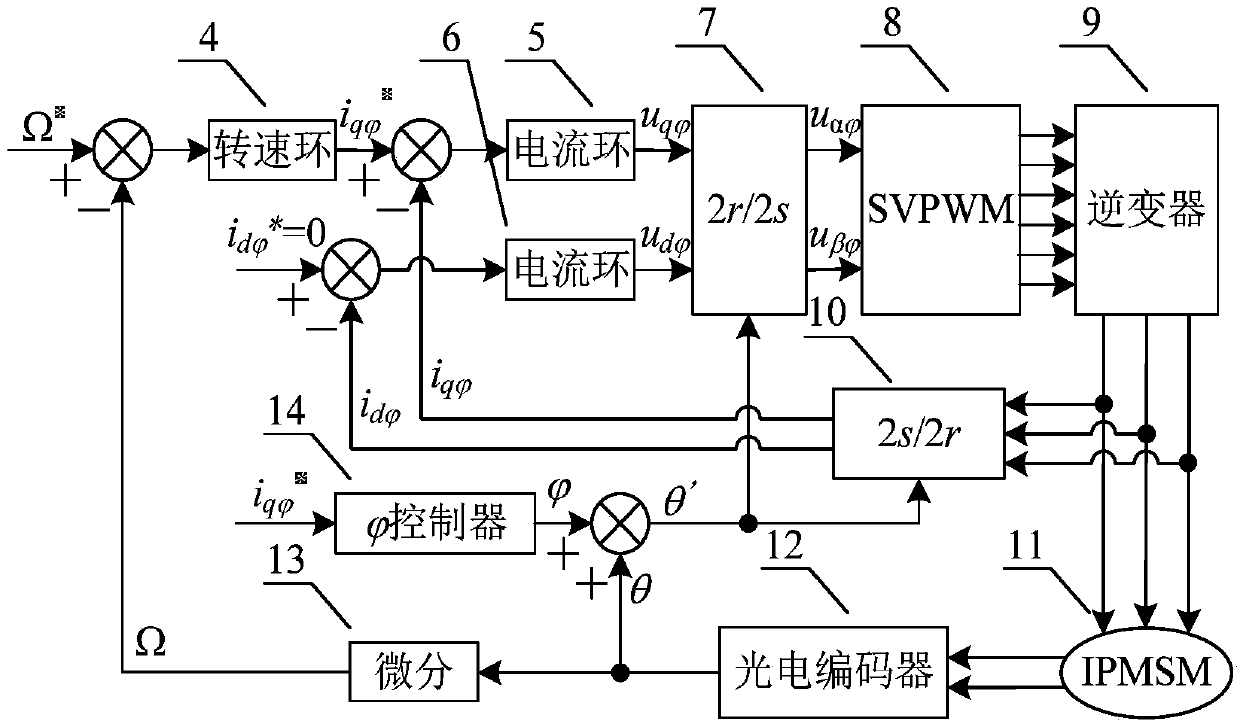

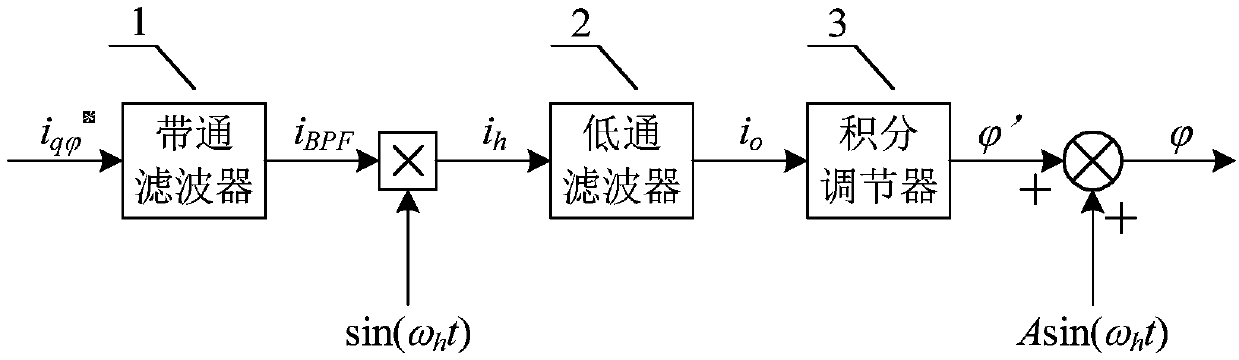

[0034] see figure 2 , the present invention uses the photoelectric encoder module 12 to collect the rotor position angle θ of the built-in permanent magnet synchronous motor 11 . The output terminal of the photoelectric encoder module 12 is connected to the input terminal of the differential module 13 , and the rotor position angle θ is calculated by the differential module 13 to obtain the motor speed Ω. Compare the motor speed Ω with the given speed Ω * For comparison, the comparison difference is input to the speed loop control module 4, and the given current is obtained through the speed loop control module 4 Output connection of speed loop control module 4 The input terminal of the controller 14, the given current input to In the controller 14. given current go through The controller 14 obtains and outputs the optimum torque angle best torque angle Add the output rotor position angle θ of the photoelectric encoder module 12 to obtain the new rotor positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com