Automatic production equipment for graphene far-infrared electrothermal film

A kind of production equipment, graphene technology, applied in the field of graphene electrothermal film processing equipment, can solve the problems of slow reaction speed, long response time of process adjustment, increased labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

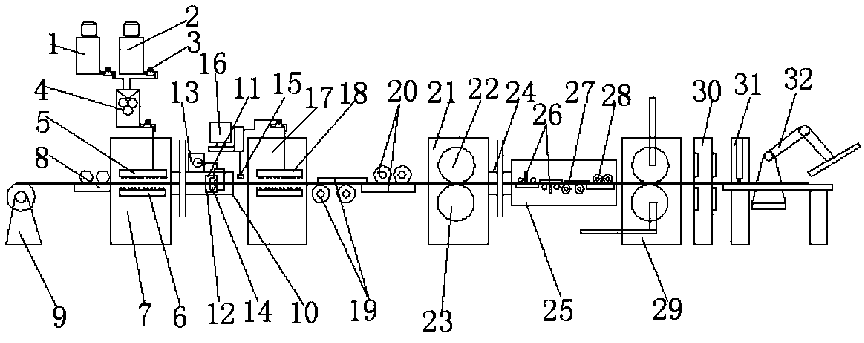

[0016] Such as figure 1The shown graphene far-infrared electrothermal film automatic production equipment is used to store the first mixing hopper 1 for stirring graphene slurry, and the first mixing hopper fully mixes and disperses graphene and its ingredients according to the proportion, and is used for storing The second mixing hopper 2 that stirs the far-infrared slurry, the second mixing hopper fully mixes and disperses the far-infrared material and its ingredients, and the output ends of the first mixing hopper 1 and the second mixing hopper 2 are respectively connected by a metering pump 3 The roller-type grinding chamber 4 is precisely metered by the metering pump, and then grinds, mixes and disperses through the grinding chamber to make it more detailed and mix more uniformly; the output end of the roller-type grinding chamber 4 is connected to the An upper coating pipe 5 and a lower coating pipe 6, a plurality of spraying nozzles are installed at intervals on the opp...

Embodiment 2

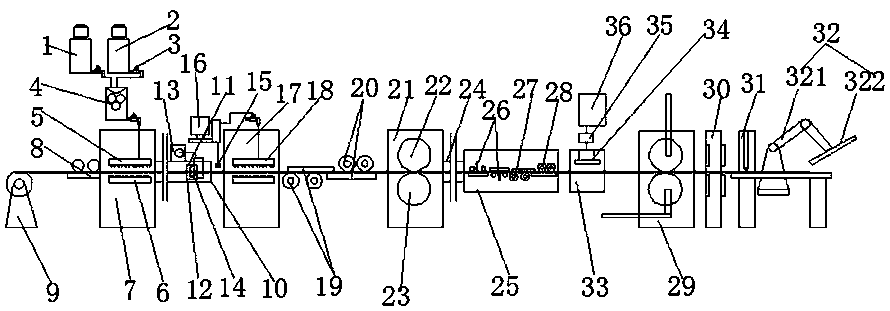

[0021] Such as figure 2 The shown graphene far-infrared electrothermal film automatic production equipment is used to store the first mixing hopper 1 for stirring graphene slurry, and the first mixing hopper fully mixes and disperses graphene and its ingredients according to the proportion, and is used for storing The second mixing hopper 2 that stirs the far-infrared slurry, the second mixing hopper fully mixes and disperses the far-infrared material and its ingredients, and the output ends of the first mixing hopper 1 and the second mixing hopper 2 are respectively connected by a metering pump 3 The roller-type grinding chamber 4 is precisely metered by the metering pump, and then grinds, mixes and disperses through the grinding chamber to make it more detailed and mix more uniformly; the output end of the roller-type grinding chamber 4 is connected to the An upper coating pipe 5 and a lower coating pipe 6, a plurality of spraying nozzles are installed at intervals on the o...

Embodiment 3

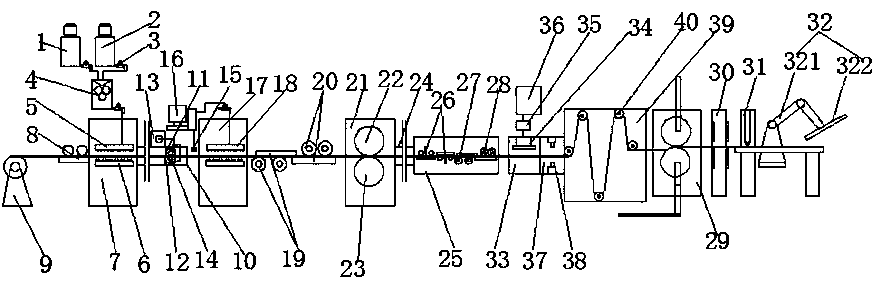

[0023] Such as image 3 The shown graphene far-infrared electrothermal film automatic production equipment is used to store the first mixing hopper 1 for stirring graphene slurry, and the first mixing hopper fully mixes and disperses graphene and its ingredients according to the proportion, and is used for storing The second mixing hopper 2 that stirs the far-infrared slurry, the second mixing hopper fully mixes and disperses the far-infrared material and its ingredients, and the output ends of the first mixing hopper 1 and the second mixing hopper 2 are respectively connected by a metering pump 3 The roller-type grinding chamber 4 is precisely metered by the metering pump, and then grinds, mixes and disperses through the grinding chamber to make it more detailed and mix more uniformly; the output end of the roller-type grinding chamber 4 is connected to the An upper coating pipe 5 and a lower coating pipe 6, a plurality of spraying nozzles are installed at intervals on the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com