High energy beam welding quality determining method, quality determining device using determining method, and welding management system using determining method

A high-energy beam and judgment method technology, which is applied in the direction of charging system, welding equipment, laser welding equipment, etc., to achieve the effect of improving judgment accuracy and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

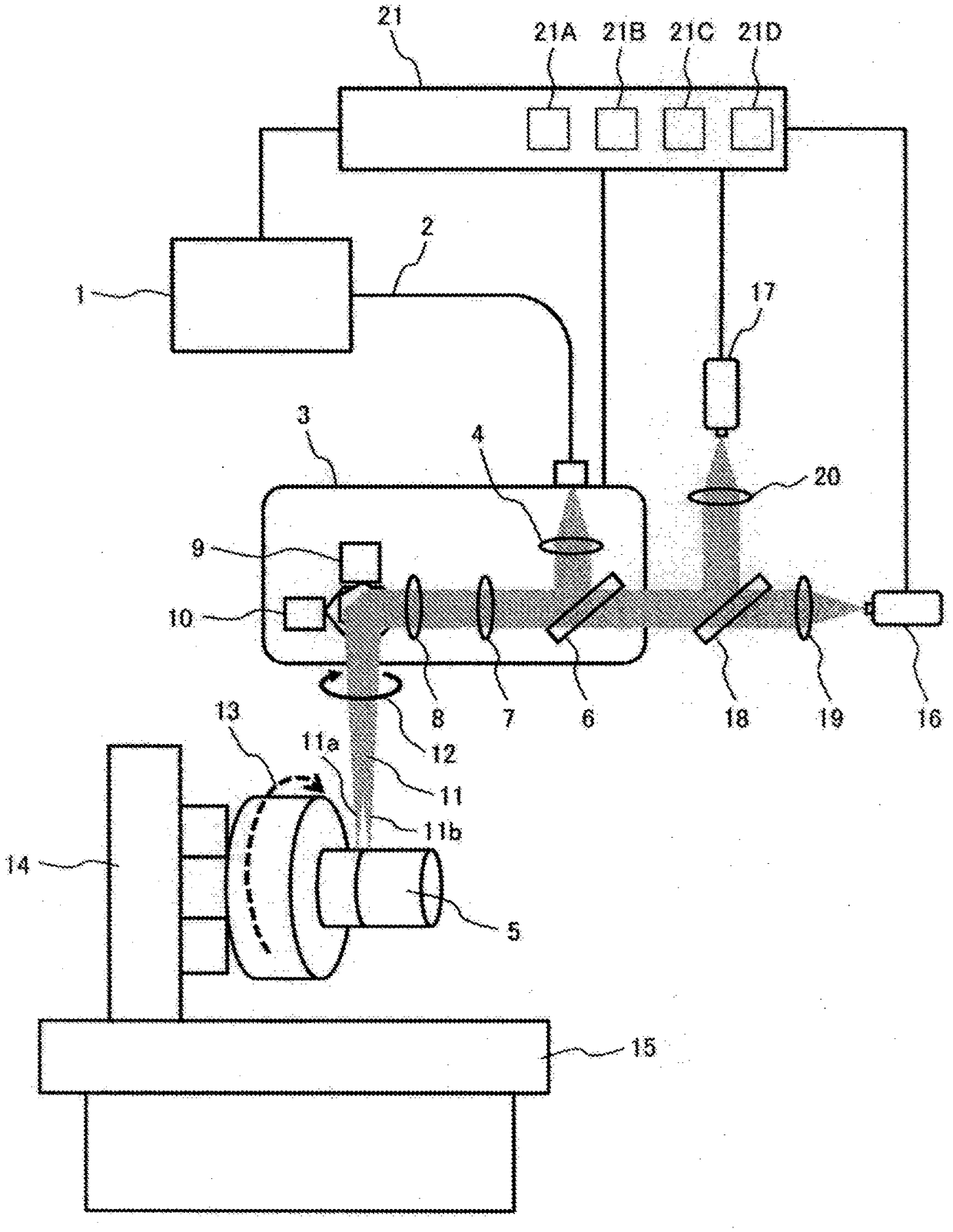

[0050] figure 1 is a schematic diagram of the laser welding apparatus of the first embodiment.

[0051] 11 represents a laser, 16 represents a camera, and 17 represents a welding light sensor. 1 indicates a laser oscillator, 2 indicates an optical fiber for laser, 3 indicates a Galvana scanner (processing head), 4 indicates a collimator lens that expands the beam width in a Galvana scanner, 5 indicates a welding object, and 6 indicates the The light emitted from the welding object 5 is transmitted to the camera 16 and the welding optical sensor 17 through a partial wavelength reflector, 7 represents the Z-axis control lens for controlling the Z-axis position of the laser 11, and 8 represents the laser that makes the beam width wider 11 focuses on the objective lens of the welding object 5, 9 represents the X-axis control Galvano mirror for controlling the X-axis position of the laser 11, 10 represents the Y-axis control Galvano mirror for controlling the Y-axis position of th...

no. 2 example

[0109] Figure 12 is a flowchart of the feedback control of the second embodiment. It should be noted that the same symbols as those in the first embodiment are used for the same or the same structural components as those in the first embodiment.

[0110] This second embodiment can be implemented using the same laser welding device as the first embodiment. In addition, the predicted value of the depth of penetration is obtained by the method described in the first embodiment. That is, it has a structure different from that of the first embodiment in the flow of feedback control.

[0111] In step 61 , when the welding time exceeds the start time Ts90 of the feedback control section 90 , the flow of the feedback control starts. In step 62, it is determined whether or not the predicted value of penetration is within the upper and lower limits (SH3, SH2). In the case of YES, the welding condition is maintained in step 63 , and it is determined in step 64 whether or not the wel...

no. 3 example

[0118] Figure 13 is a schematic diagram of the laser welding apparatus of the third embodiment.

[0119] The same symbols as in the first embodiment are used for the same structural components as in the first embodiment. For the same structural components as those of the first embodiment, explanations are omitted.

[0120] In the present third embodiment, the welding target 5A is different from the first embodiment. Others are the same as the first embodiment. The welding object 5A is a fuel injection fitting. The welding joint of the welding object 5A is a lap welding structure.

[0121] In the present third embodiment, although lap welding is applied, the weld joint structure is not limited thereto. In addition, in the third embodiment, the type of laser to be used, the material to be welded, and the laser welding conditions are not limited thereto.

[0122] In addition, the feedback control described in the second embodiment can also be applied in this third embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com