Portable dust removal equipment for textile production workshop

A technology for production workshops and dust removal equipment, applied in the field of textile production, can solve the problems of cumbersome installation, easy clogging of filters by impurities, high power consumption of dust removal equipment, etc., and achieves the effect of solving cumbersome installation, reducing production costs, and convenient and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

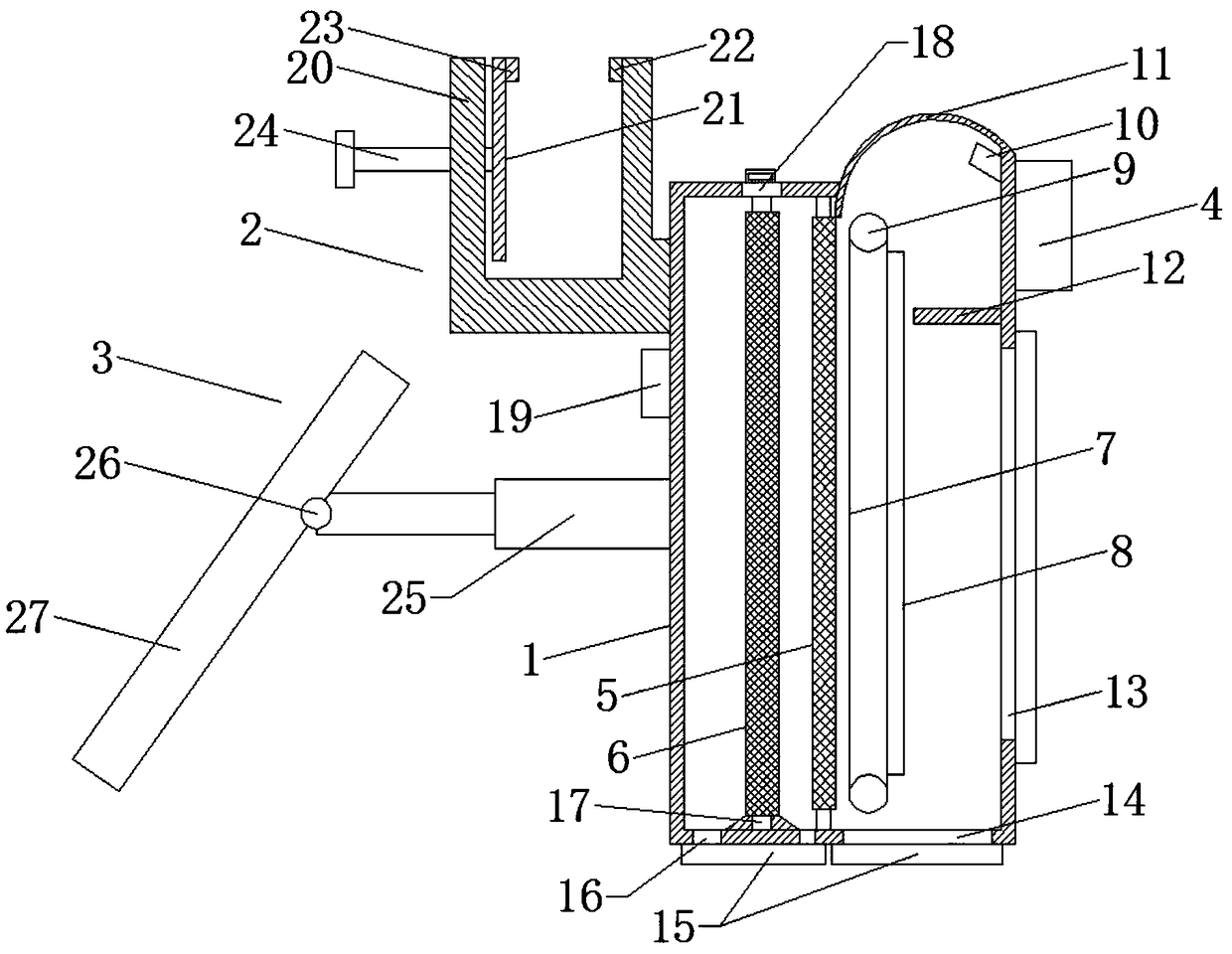

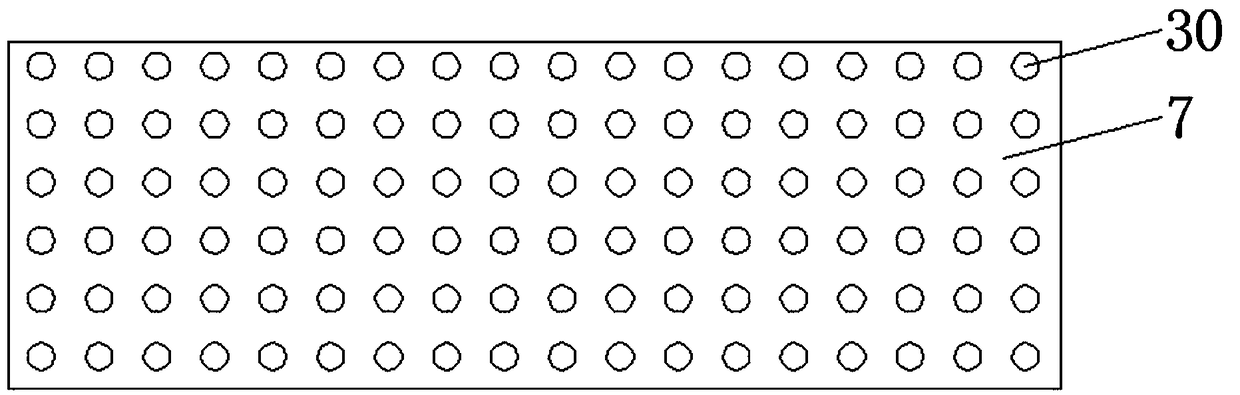

[0016] see figure 1 , in an embodiment of the present invention, a portable and installed dust removal equipment for textile production workshops, including a housing 1, a fixed structure 2, a fan 4, an electrostatic dust removal plate 5 and a filter screen plate 6; the fixed structure 2 is fixed on the housing 1 outside (for figure 1 The left side of the middle), the fan 4 is installed on the inner side of the housing 1, the outer side of the housing 1 faces the outdoors, and the inner side faces the workshop, and the electrostatic precipitator plate 5 is fixedly installed in the housing 1 to perform electrostatic dust removal on the passing air. The outer side of the dust removal plate 5 is provided with a detachable filter screen plate 6, the bottom of the housing 1 corresponding to the lower end of the filter screen plate 6 is provided with a draw-in groove 17, the filter screen plate 6 is inserted into the draw-in slot 17, and the upper end is fixed with a 1 The sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com