A modification method of Radix Astragali polysaccharide and application of the modified Radix Radix Polysaccharide

A modification method and technology of heptostilbene polysaccharide are applied in the directions of medical preparations containing active ingredients, pharmaceutical formulas, allergic diseases, etc., which can solve the problems of difficulty in later purification, low solubility, and low extraction rate, and achieve good application and development. Prospects, the effect of improving biological activity, improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

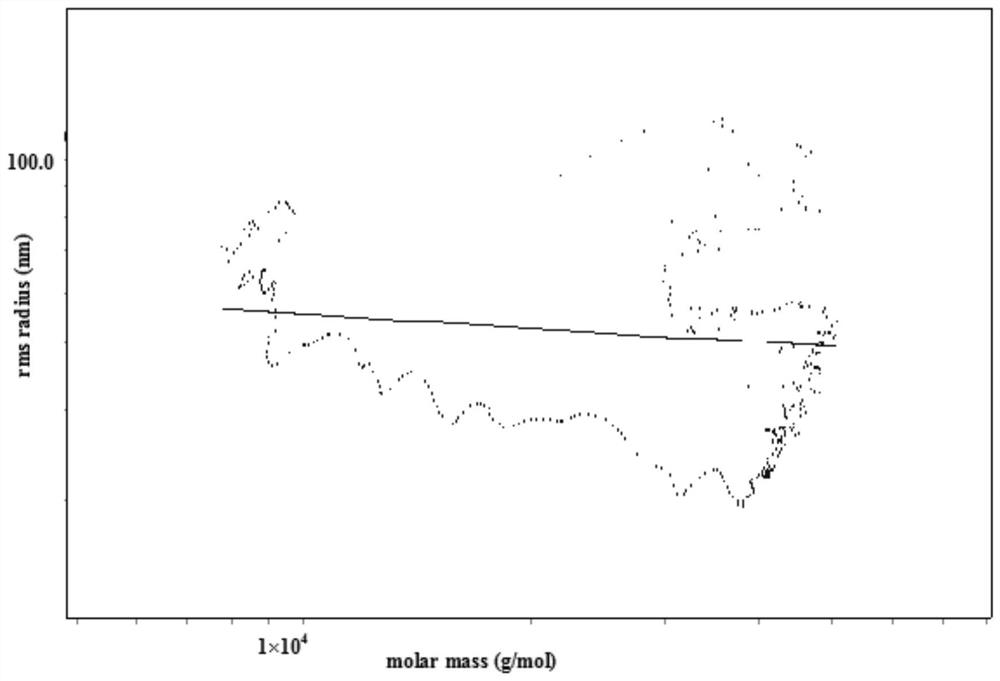

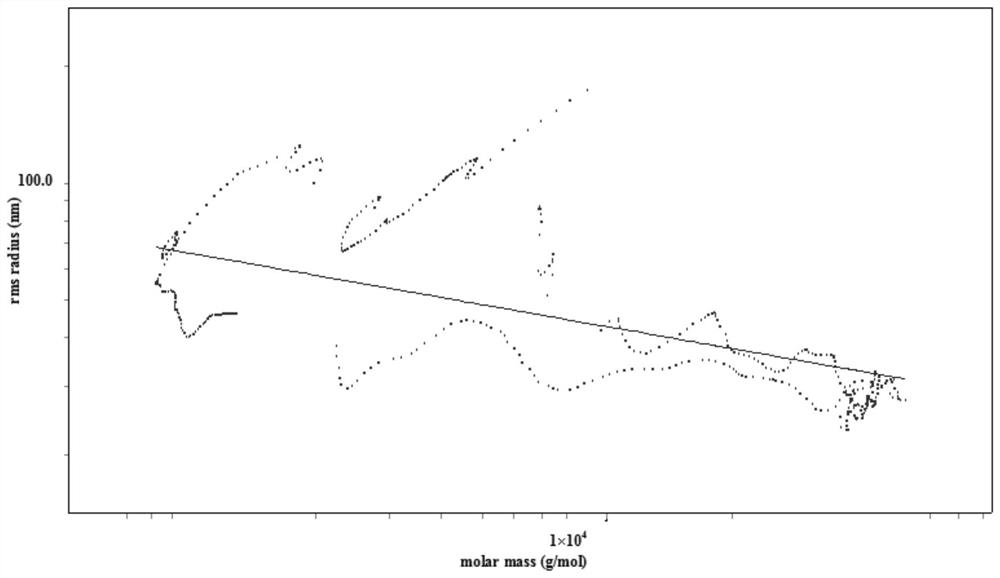

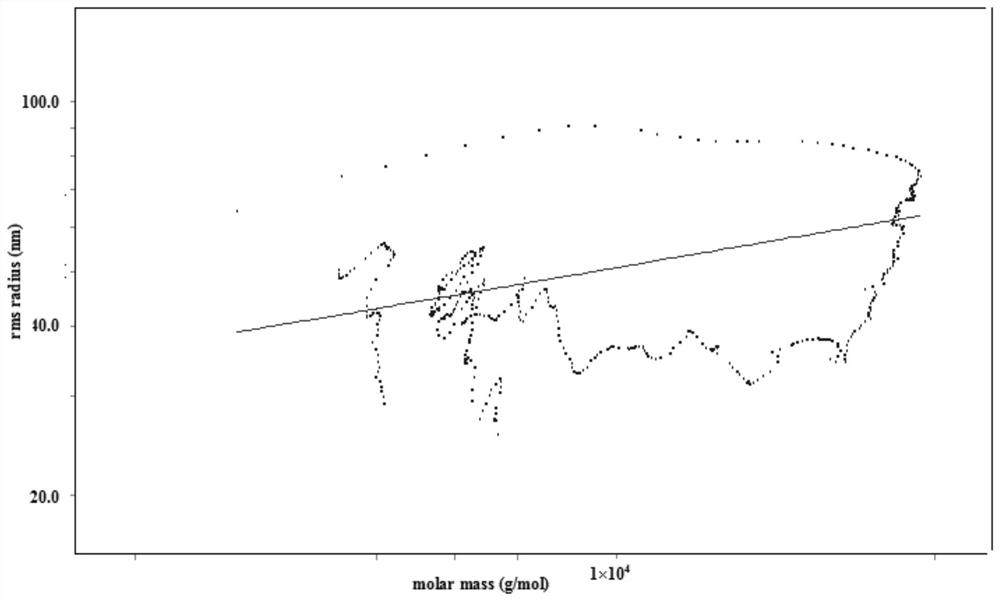

Image

Examples

Embodiment 1

[0065] The modification method of Radix Astragali polysaccharide specifically comprises the following steps:

[0066] (1) Radix Astragali, washed, crushed through an 80-mesh sieve, degreased once with 3 times the amount of ethyl acetate and 85% ethanol, 0.5h each time, and dried.

[0067] (2) Weigh 1.0 g of defatted Radix Radix Radix Dry Powder, add 10 mL of tap water, add citric acid-sodium citrate buffer to adjust pH=5, and perform enzymolysis with a compound enzyme, the amount of which is 1.0% of the mass of Radix Radix Radix %, the enzymatic hydrolysis temperature is 45°C, the enzymatic hydrolysis time is 1h, and no inactivation is required after enzymatic hydrolysis; the compound enzyme is composed of cellulase and papain, and the mass ratio of the two is 2:1.

[0068] (3) After enzymatic hydrolysis with complex enzymes, ultrasonication is performed, ultrasonic temperature is 60°C, ultrasonic power is 40W, ultrasonic time is 30min, ultrasonic treatment is performed once, ...

Embodiment 2

[0069] Example 2 Preparation of Astragalus Polysaccharides by Traditional Hot Water Extraction and Combined Enzyme Combined with Ultrasonic Modification of Astragalus Polysaccharides

[0070] (1) Traditional hot water extraction method: Take 1.0g of defatted medicinal powder, add 10mL of tap water, warm soak at 60°C for 3 times, each time for 1h, filter, combine the filtrate, concentrate the filtrate to 1 / 3 of the volume of the filtrate, add ethanol to make The volume concentration of ethanol is 70%, standing overnight at 4° C., centrifuging to obtain a precipitate, and vacuum freeze-drying the precipitate to obtain hot-water-extracted Heqi polysaccharide (HPS-R). The polysaccharide yield was 6%, and the polysaccharide content was 80%.

[0071] (2) Preparation of Heqi polysaccharide (HPS-MC1) and Heqi polysaccharide (HPS-MC2) by compound enzyme combined with ultrasonic modification of Heqi polysaccharide:

[0072] The preparation method of step (1) and step (2) is identical w...

Embodiment 11

[0114] The modification method of Radix Astragali polysaccharide specifically comprises the following steps:

[0115] (1) Radix Astragali, washed, crushed through a 50-mesh sieve, degreased twice with 5 times the amount of ethyl acetate and 95% ethanol, 2 hours each time, and dried.

[0116] (2) Weigh 1.0 g of defatted Radix Radix Dry Powder, add 30 mL of tap water, add citric acid-sodium citrate buffer solution to adjust pH=3, and carry out enzymolysis with compound enzyme, the amount of compound enzyme added is 6.0% of the mass of Radix Radix Radix %, the enzymatic hydrolysis temperature is 40°C, the enzymatic hydrolysis time is 2 hours, and no inactivation is required after enzymatic hydrolysis; the compound enzyme is composed of cellulase and papain, and the mass ratio of the two is 5:1.

[0117] (3) After enzymatic hydrolysis with complex enzymes, ultrasonication is performed, ultrasonic temperature is 30°C, ultrasonic power is 60W, ultrasonic time is 50min, ultrasonic tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com