Light-colored solvent-resistant natural rubber vulcanized rubber and preparation method thereof

A natural rubber and solvent-resistant technology, applied in the field of organic solvent-resistant rubber, can solve the problem that the overall performance is inferior to natural rubber, etc., and achieve the effect of improving the organic solvent-resistant performance and reducing the penetration space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

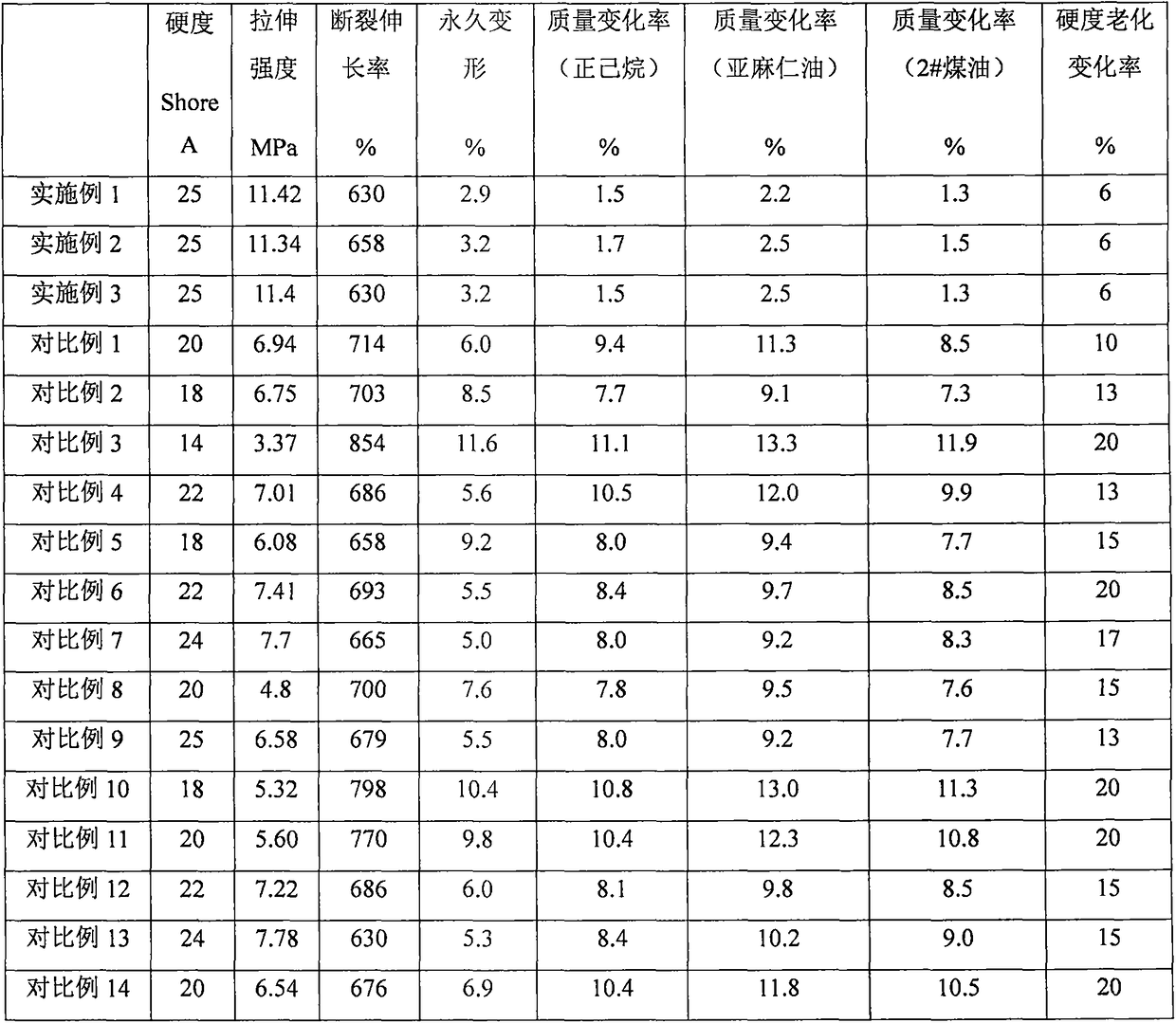

Examples

preparation example Construction

[0014] A preparation method of light-colored solvent-resistant natural rubber vulcanizate, comprising the following steps:

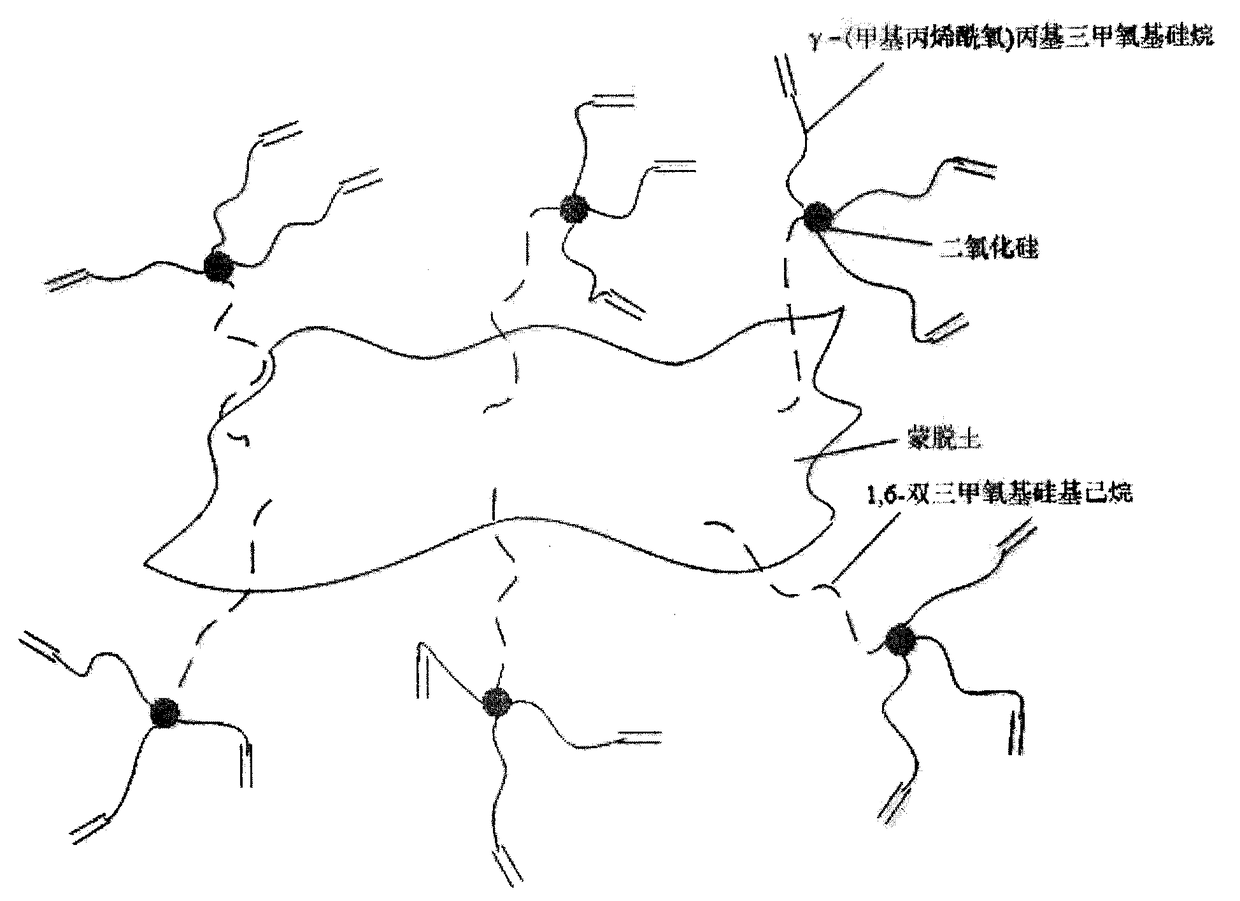

[0015] Step 1: Dissolve 4-6g of 1,6-bistrimethoxysilylhexane in 500mL ethanol solution, add 50g of montmorillonite, stir and reflux in a water bath at 70-90°C for 2-4h, add 25g of silicon dioxide, 60 Reflux in a water bath at -80°C for 2-4h, add 1-2g of γ-(methacryloyloxy)propyltrimethoxysilane dropwise, reflux in a water bath at 50-70°C for 4-6h, cool, filter, and wash with absolute ethanol 3 times, Vacuum drying at 60°C and grinding to obtain a functional hybrid filler, wherein the average aspect ratio of montmorillonite is 30-100, the average particle size is 1-20 μm, and the average particle size of silica is 100-300nm;

[0016] Step 2: Roll 100 parts by mass of natural rubber on an open mill, add 2 parts by mass of stearic acid, 5 parts by mass of zinc oxide, 1.5 parts by mass of anti-aging agent 264, and 75-100 parts by mass of the functional compl...

Embodiment 1

[0031] Step 1: Dissolve 4g of 1,6-bistrimethoxysilylhexane in 500mL ethanol solution, add 50g of montmorillonite, stir and reflux in a water bath at 90°C for 2h, add 25g of silicon dioxide, reflux in a water bath at 60°C for 4h, drop Add 2g of γ-(methacryloyloxy)propyltrimethoxysilane, reflux in a water bath at 50°C for 6 hours, cool, filter, wash with absolute ethanol three times, dry in vacuum at 60°C, and grind to obtain a functional hybrid filler. The average length-to-diameter ratio of desoiled soil is 30, the average particle size is 20 μm, and the average particle size of silica is 100 nm. The structure diagram of the functional hybrid filler is shown in figure 1 ;

[0032] Step 2: Roll 100 parts by mass of natural rubber on an open mill, and add 2 parts by mass of stearic acid, 5 parts by mass of zinc oxide, 1.5 parts by mass of anti-aging agent 264, and 75 parts by mass of the functional hybrid filler obtained in step 1 , 50 parts by mass of naphthenic oil, 1.5 parts...

Embodiment 2

[0035] Step 1: Dissolve 6g of 1,6-bistrimethoxysilylhexane in 500mL ethanol solution, add 50g of montmorillonite, stir and reflux in a water bath at 70°C for 4h, add 25g of silicon dioxide, reflux in a water bath at 80°C for 2h, drop Add 1g of γ-(methacryloyloxy)propyltrimethoxysilane, reflux in a water bath at 70°C for 4 hours, cool, filter, wash with absolute ethanol three times, dry in vacuum at 60°C, and grind to obtain a functional hybrid filler. The average aspect ratio of desoiling is 100, the average particle size is 1μm, and the average particle size of silica is 300nm;

[0036] Step 2: Roll 100 parts by mass of natural rubber on an open mill, and add 2 parts by mass of stearic acid, 5 parts by mass of zinc oxide, 1.5 parts by mass of anti-aging agent 264, and 100 parts by mass of the functional hybrid filler obtained in step 1 , 60 parts by mass of naphthenic oil, 0.5 parts by mass of accelerator M, 1.2 parts by mass of sulfur, to obtain rubber compound;

[0037] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com